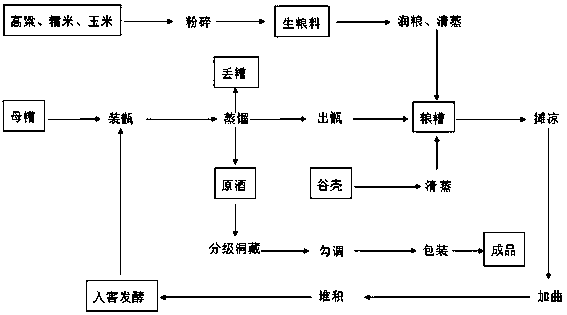

Pure, mellow, soft, harmonious and palatable Yu-flavor liquor production technology

A production process, Yuxiang type technology, applied in the field of Yuxiang type liquor production technology, can solve the problem of unscientific storage time and other problems, and achieve the effects of easy cooking, improving steam penetration efficiency, and mellow and sweet liquor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Take 700kg of sorghum, 200kg of glutinous rice, and 100kg of corn that are clean, free of impurities, and dust-free. The water content is controlled at 12%. Shell 200kg, water content controlled at 11%, steamed for 1 hour, quick-dried and cooled for later use; put the grain in the air-drying bed, add 500kg of hot water at 50°C, mix evenly and pile up the grain, moisten the grain 2 hours in advance, divide Moisturize the grain twice, add 300kg of water for the first time, after the water is fully absorbed, add 200kg of water to make the grain fully absorb water, mix in 50kg of spare rice husk, mix evenly, put on the steamer, and keep the air in the steamer when it is on the steamer. Layer and evenly put on the retort. After the retort is put on, cover and steam the grains under normal pressure for 1 hour, uncover the pot lid, add 400kg of hot water at 85°C, stir the grain while splashing water, so that the grain can fully and evenly absorb the water, and then cover the po...

Embodiment 2

[0041] Take 720kg of sorghum, 180kg of glutinous rice, and 110kg of corn that are clean, free of impurities, and dust-free through air sifting. The water content is controlled at 13%. The shell is 240kg, the water content is controlled at 9%, steamed for 1.2 hours, and quickly aired and cooled for later use; put the grain in the drying bed, add 550kg of hot water at 55°C, mix and evenly pile up the moist grain, so that the grain can fully absorb water, Stir in 60kg of spare rice husks, stir evenly, and put on the steamer. When putting on the steamer, keep seeing gas, layering, and evenly steam the rice. Mix the grain while splashing water, so that the grain can fully and evenly absorb the water, then cover the pot and steam the grain for more than 40 minutes, fully steam the grain, take it out for use; take 1000kg of fermented mature grains, add 40kg of spare grain After the shell is mixed evenly, put it into the retort, and install the grains while exploring the steam to ensu...

Embodiment 3

[0043] Take 1300kg of sorghum, 360kg of glutinous rice, and 180kg of corn that are clean, free of impurities, and dust-free. The water content is controlled at 14%. The shell is 450kg, the water content is controlled at 13%, steamed for 1 hour, and quickly dried and cooled for later use; put the grain in the drying bed, add 900kg of hot water at 60°C, mix and evenly pile up the grain, moisten the grain 2 hours in advance, divide Moisturize the grain twice, add 500kg of water for the first time, after the water is fully absorbed, add 400kg of water to make the grain fully absorb water, mix in 400kg of spare rice husks, mix evenly, put on the retort, and keep the gas and separate when putting on the retort Layer and evenly put on the retort. After putting on the retort, cover and steam the grains under normal pressure for 1 hour, uncover the pot lid, add 700kg of hot water at 90°C, stir the grain while splashing water, so that the grain can fully and evenly absorb the water, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com