Novel vibration reduction road structure and construction method thereof

A road structure and a new type of technology, applied to roads, roads, on-site paved condensate pavement, etc., can solve the problems of unsatisfactory vibration reduction effect and limited life, so as to improve the overall stability, reduce structural vibration, improve Effects on Pavement Structural Life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

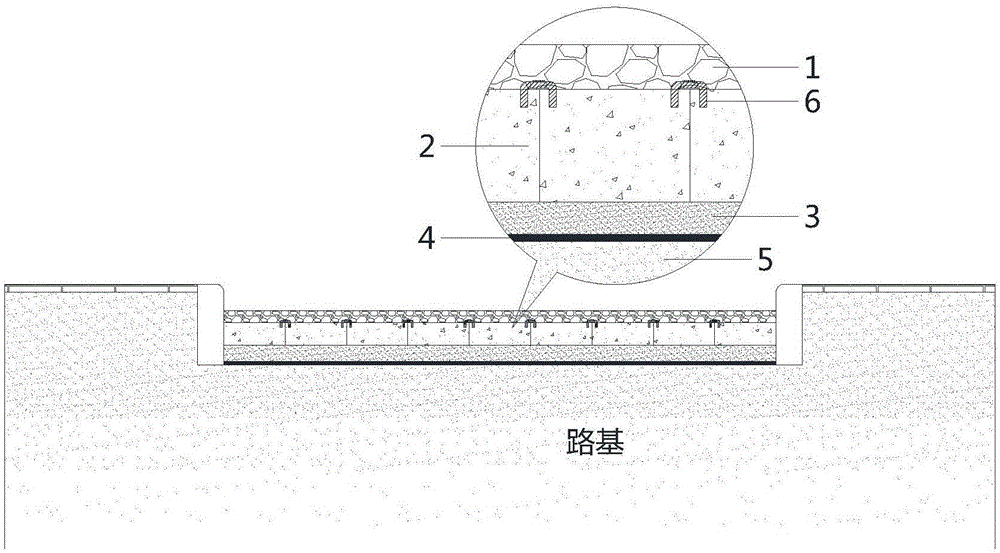

[0041] see figure 1 , image 3 , Figure 4 , the damping road structure of the present embodiment comprises asphalt mixture pavement layer 1, precast concrete road slab 2 and roadbed 5 from top to bottom, and a vibration isolation wall is arranged between the precast concrete road slab 2 and roadbed 5 CA mortar layer 3, a waterproof layer 4 is set between the CA mortar layer 3 and the roadbed 5; the CA mortar layer 3 and the waterproof layer 4 are naturally separated, the asphalt mixture pavement layer 1 and the precast concrete road slab The 2 are connected by the permeable layer oil and the sticky layer.

[0042] Wherein, the asphalt mixture pavement layer 1 includes an open graded anti-skid wear layer (OGFC) and a densely graded asphalt mixture (AC) as a road surface layer, and the preferred layer thickness and label are 30mm thick from top to bottom. OGFC- 10. 40mm thick AC-10.

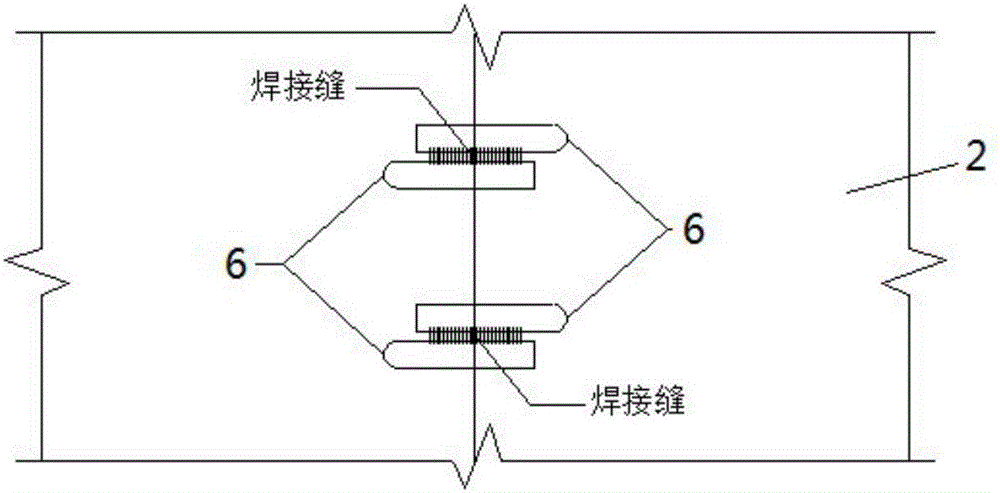

[0043] Wherein, the prefabricated concrete road slab 2 has a thickness of 180mm, and an up...

Embodiment 2

[0055] The damping road structure of the present embodiment and the construction method thereof are basically the same as the first embodiment, and their difference is that in the present embodiment, the road surface layer of the asphalt pavement layer 1 preferably adopts asphalt horseshoe grease macadam ( SMA), the preferred layer thickness is 60mm, and the label is SMA-13.

Embodiment 3

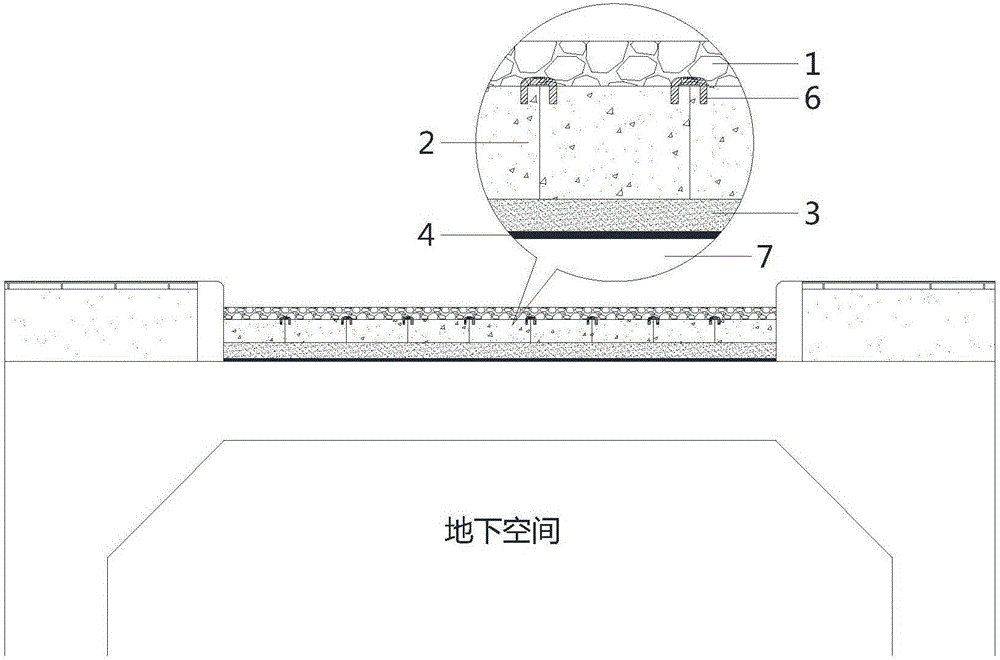

[0057] see figure 2 , image 3 , Figure 4 , the damping road structure of the present embodiment comprises asphalt pavement layer 1, precast concrete road slab 2 and underground space roof 7 from top to bottom, and the precast concrete road slab 2 and underground space roof 7 are arranged between the Based on the vibration-isolated CA mortar layer 3, the asphalt mixture pavement layer 1 and the precast concrete road slab 2 are connected through a penetrating oil layer and an adhesive layer.

[0058] The construction method of the damping road structure, its paving sequence is as follows:

[0059] (1) Prefabricate concrete road slabs in the factory, and pre-embed steel bars 6 on the concrete road slabs;

[0060] (2) The upper surface of the underground space roof 7 is roughened or chiseled, and applied as a waterproof layer;

[0061] (3) paving the CA mortar layer 3 on the top surface of the rough underground space roof 7;

[0062] (4) Before the CA mortar layer 3 is ful...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com