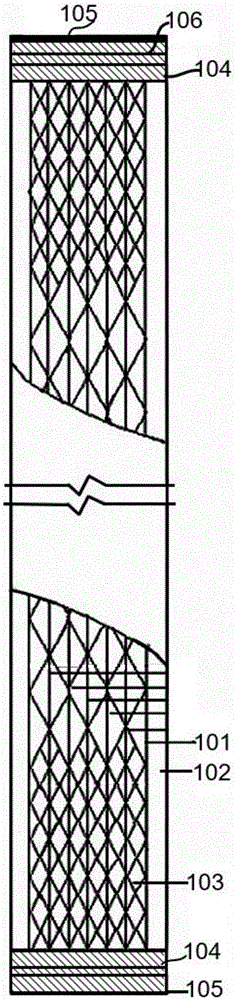

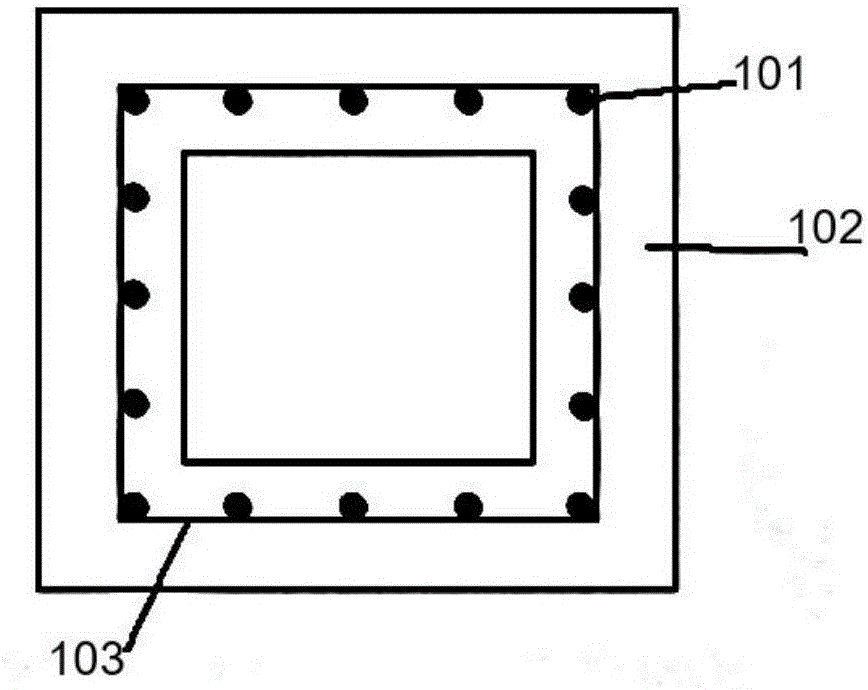

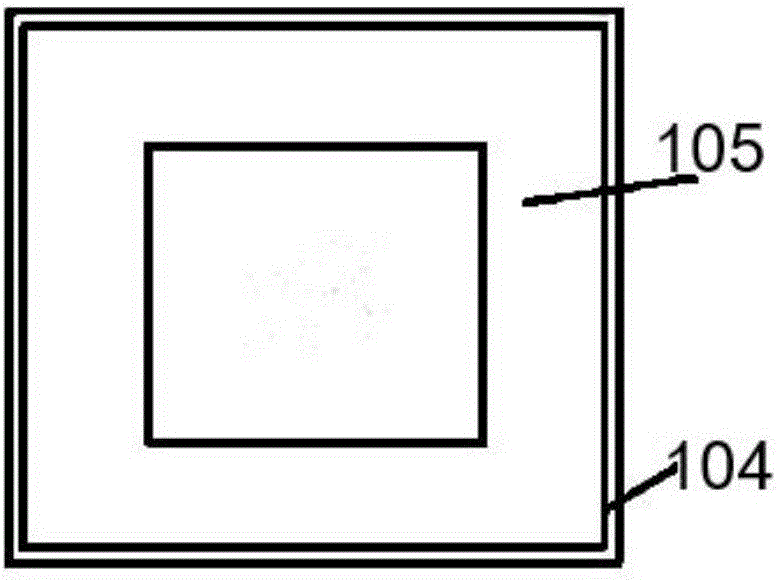

Prestressed concrete precast pile in form of mesh reinforcements

A technology of concrete prefabricated piles and concrete piles, which is applied in sheet pile walls, buildings, and foundation structure engineering, etc. It can solve the problems of less research on the anti-seismic performance of prestressed high-strength concrete pipe piles, and achieve convenient purchase, convenient material acquisition, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 5

[0041] Embodiment five, pipe pile performance test

[0042] Experiment 1~Experiment 6

[0043]

[0044]

[0045] In embodiment N1 to embodiment N7, N is 1 to 5, and the other components of each embodiment in N1 are the same, and the proportions of additives are different.

[0046] When N is 1 to 5, the proportions of additives are as follows:

[0047] Water reducer 6.1, rust inhibitor (RI steel rust inhibitor) 4.5, retarder (molasses retarder) 0.3, EVA6.5.

[0048] Water reducer 9.2, rust inhibitor (sodium benzoate) 3.2, retarder (hydroxy carboxylic acid) 0.1, EVA7.5.

[0049] Water reducing agent 5.1, rust inhibitor (RI steel rust inhibitor) 5.1, retarder (molasses retarder) 0.2, EVA8.5.

[0050] Water reducer 7.3, rust inhibitor (sodium benzoate) 2.2, retarder (lignosulfonate retarder) 0.4, EVA5.5.

[0051] Water reducer 10.3, rust inhibitor (JK-H2O compound amino alcohol) 6.2, retarder (lignosulfonate retarder) 0.5, EVA10.5.

[0052] The experimental result of em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com