Distribution circuit steel pipe and composite material mixing electric pole

A technology of composite materials and distribution lines, applied in the field of electric poles, can solve the problems of small elastic modulus and large deformation of composite materials, and achieve the effects of large bearing capacity, reasonable bearing capacity and strong wind resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

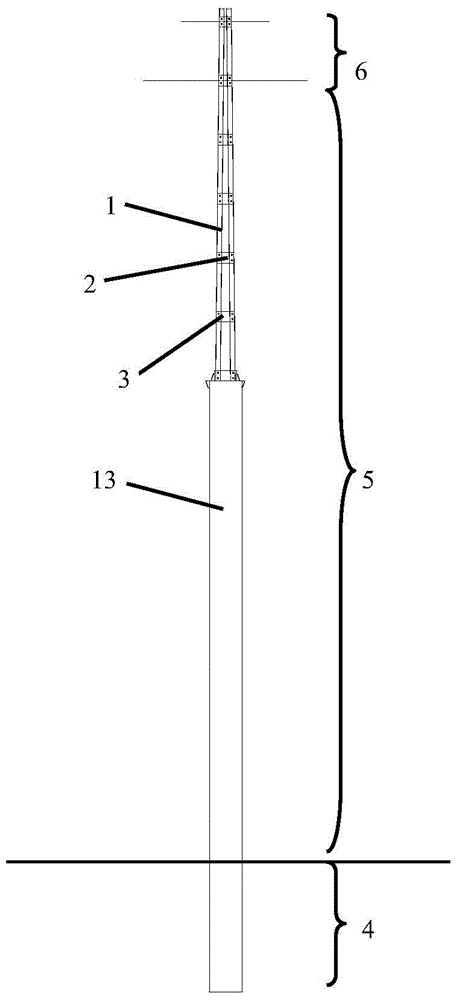

[0049] A composite rod is composed of a column 1 and a panel 2 made of composite materials including carbon fiber and reinforced resin, and the surfaces of the column 1 and the panel 2 are respectively coated with a coating including a coloring agent and an anti-aging additive. The composite rod and the steel pipe 13 Connected into poles through flanges.

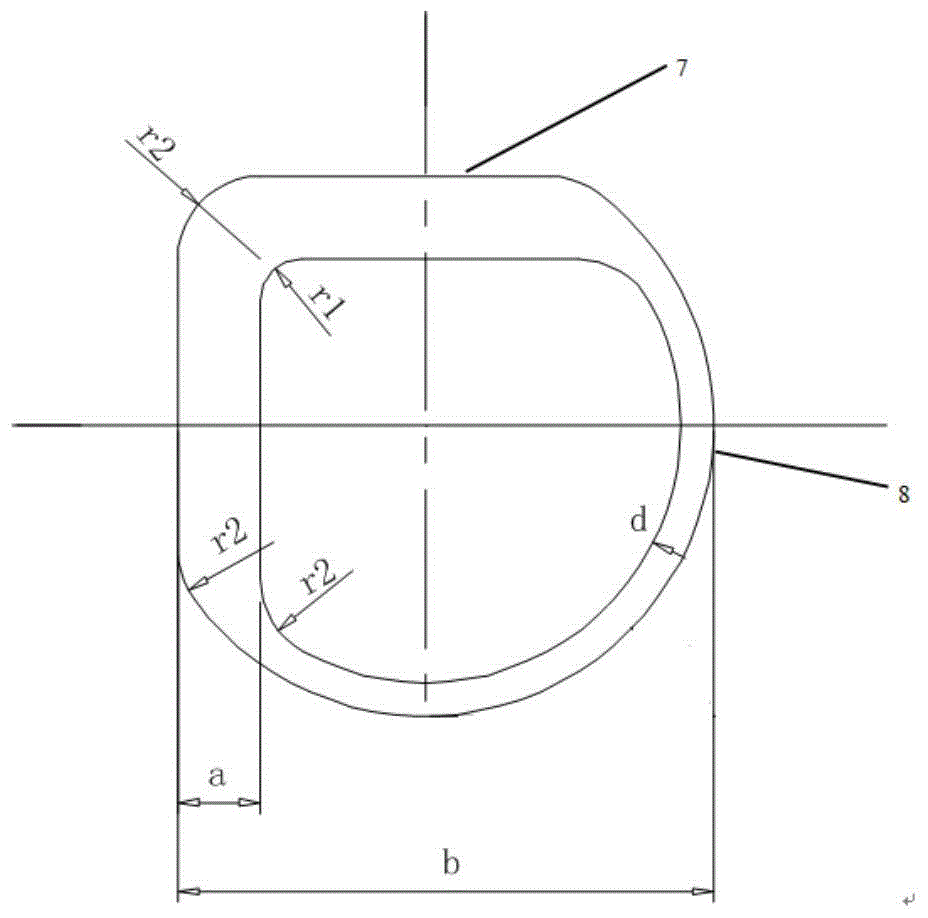

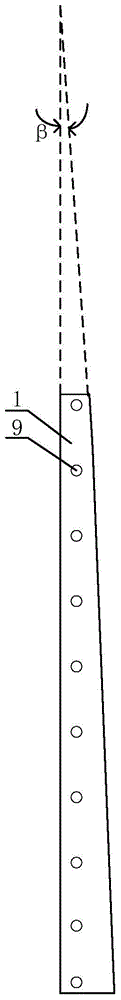

[0050] The column 1 is a D-shaped tube with a "D" shape in cross section. The thickness of the side wall 7 is 20 mm, and the thickness of the arc wall 8 is 7 mm. The angle between the two side walls 7 is 90°. The radius of the outer wall chamfer at the place is equal to 20mm, the radius of the inner wall chamfer is 8mm, the radius of the screw hole 9 is 12mm, the radius of the through hole 10 is 15mm, and the shrinkage angle β of the D-shaped tube is 0.38°. The panel 2 has a thickness of 28mm, a length of 400mm, and a width of 180mm.

[0051] Arrange the four columns 1 at the four corners of the composite rod with a square ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com