Aviation diesel engine piston combustion chamber and combustion system

A combustion system and combustion chamber technology, applied to pistons, mechanical equipment, engine components, etc., can solve the problems of prolonging fuel injection time, affecting aviation flight mileage, increasing fuel consumption rate, etc., achieving low engine weight requirements and avoiding severe fuel consumption Hit the wall and burn efficiently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

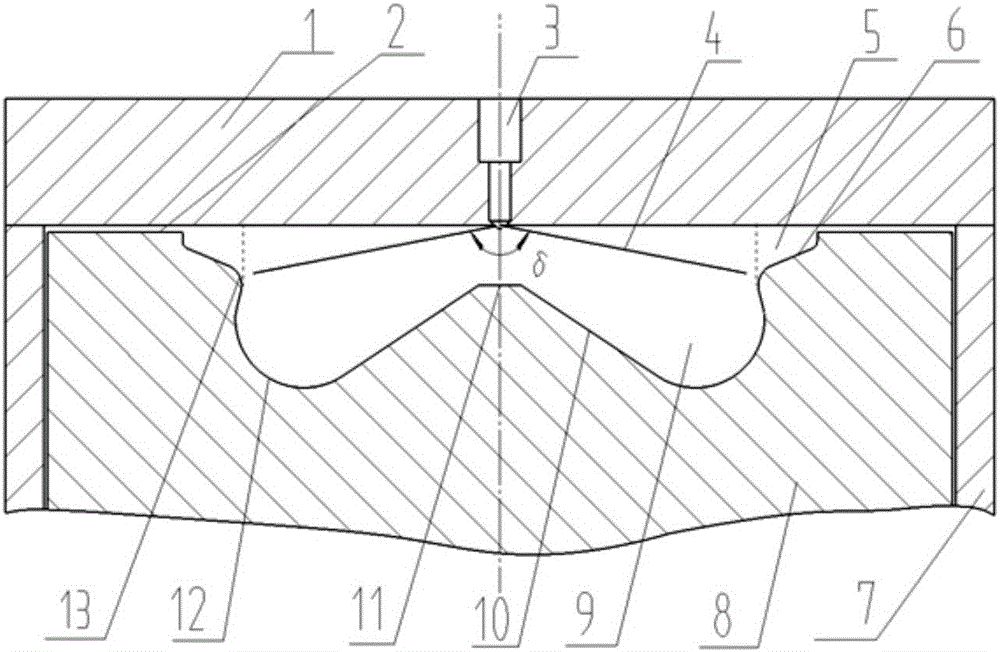

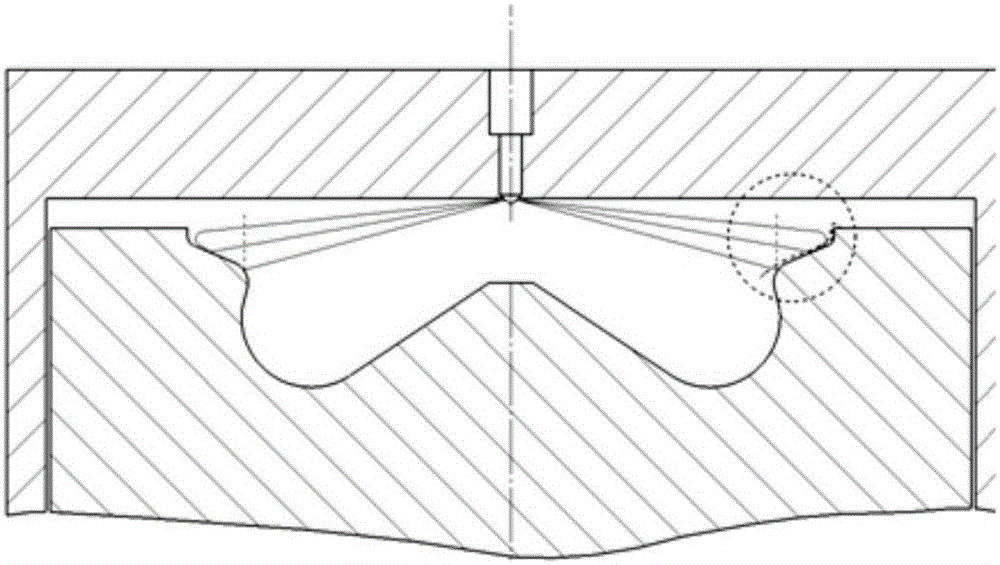

[0026] Such as Figure 1 to Figure 5 As shown, the piston combustion chamber and the combustion system of the aviation diesel engine include a cylinder head 1 and a cylinder barrel 7, a piston 8 is arranged in the cylinder barrel 7, a cavity of the combustion chamber is formed between the top of the piston and the cylinder head, and a combustion chamber is arranged on the top of the piston. Chamber pit 9, the top of the piston on the edge of the combustion chamber is provided with a groove 5, the groove is located outside the pit of the combustion chamber, and the cylinder head 1 is provided with an injector 3.

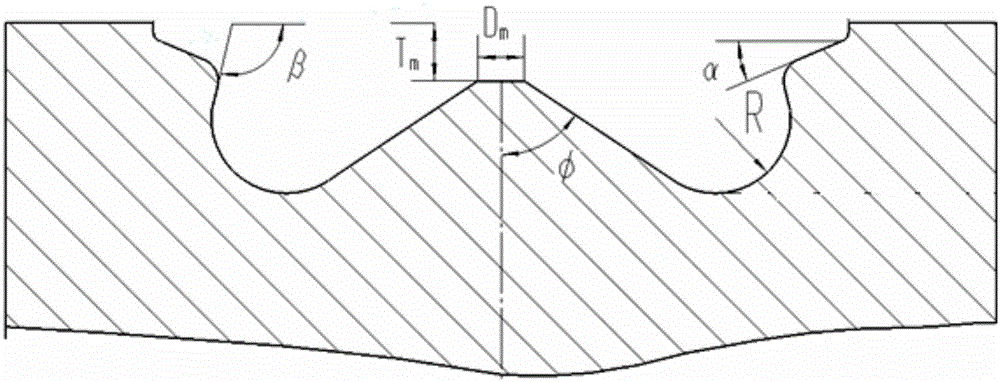

[0027] The combustion chamber pit 9 is located at the piston head, and the combustion chamber pit is an ω-shaped pit. The entire combustion chamber pit is symmetrical about the piston ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com