Antiproton rocket engine

A rocket engine and antiproton technology, which is applied in the direction of rocket engine devices, machines/engines, mechanical equipment, etc., can solve problems such as impact, engine use condition restrictions, harmful substance emissions, etc., to achieve high efficiency, increase payload quality, and space The effect of high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will be described in more detail below in conjunction with the accompanying drawings.

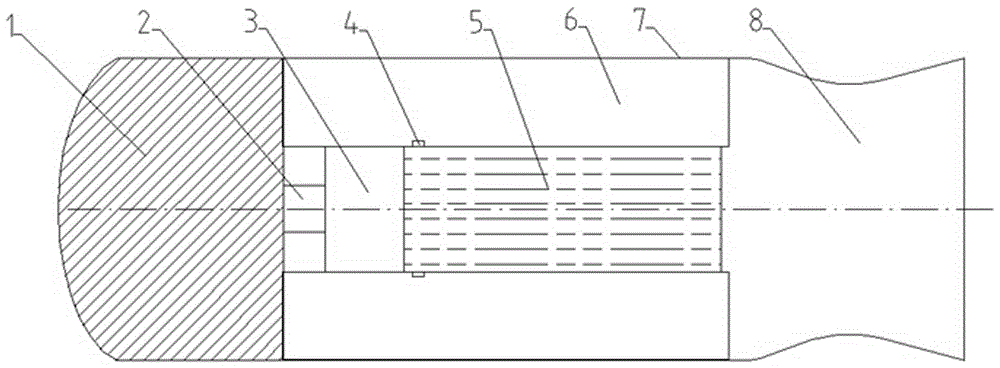

[0016] See attached figure 1 , an antiproton rocket engine, comprising an engine casing 7, an antiproton generator 1 is installed at the front end of the engine casing 7, a nozzle assembly 8 is arranged at the tail, and the middle section includes an antiproton extraction pipeline 2 and an annihilation device 3 , the heat conversion chamber 5 and the air storage box 6; the air storage box 6 is fixedly installed on the inner wall surface of the engine housing 7; one side of the air storage box 6 has an air-introduction hole 4, and a valve is installed on the air-induction hole 4 Hydrogen is stored in the gas storage box 6; an annihilation device 3 is provided on one side of the gas storage box 6, and one end of the annihilation device 3 is connected to the antiproton generator 1 through an antiproton extraction pipeline 2, The other end is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com