Flameproof submersible electric pump for dual-cooling efficient mining

A submersible electric pump and explosion-proof technology, which is applied to components of pumping devices for elastic fluids, pumps, pump devices, etc., can solve the problem of high motor protection level requirements, difficult product performance guarantees, and reduced reliability and life. and other problems, to achieve the effect of solving liquid flow disturbance, sewage pumping thoroughly, and reducing heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

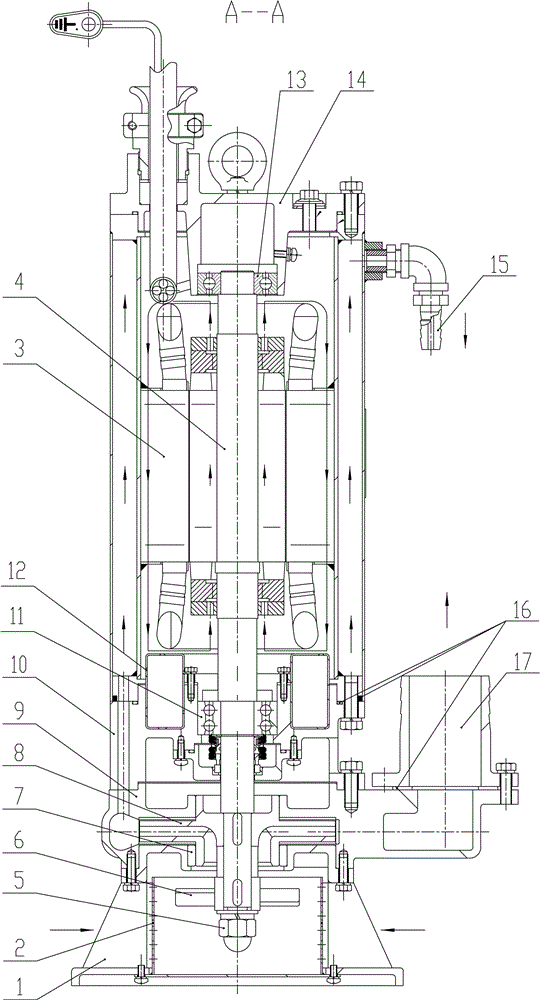

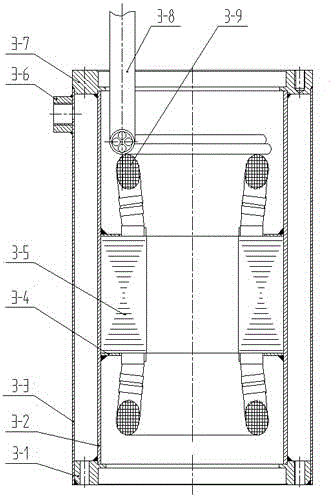

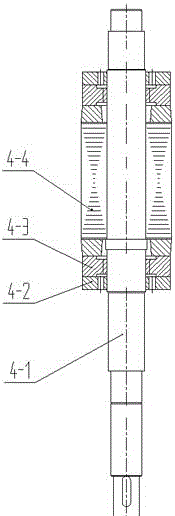

[0029] The following is attached Figure 1-4 The present invention is further described in detail.

[0030] as attached figure 1 , 2 , 3 and 4, a dual-cooling high-efficiency mining explosion-proof submersible pump, which includes a base 1, a pump volute 9, a lower bearing assembly 10, a stator assembly 3, a rotor assembly 4 and an upper bearing assembly 14 , the pump volute 9 is provided with a water outlet 17, the base 1 is connected to the water inlet filter 2 by bolts, the stator assembly 3 includes a stator core, an outgoing cable 3-8 and a winding 3-9, the The stator core is welded by the lower frame ring 3-1, the stator inner sleeve 3-2, the stator outer sleeve 3-3, the stator tooth pressure plate 3-4, the stator punching plate 3-5 and the upper frame ring 3-7. As a result, the outer cavity of the motor is formed between the stator inner sleeve 3-2 and the stator outer sleeve 3-3. The base 1, the pump volute 9, the lower frame ring 3-1 and the upper frame ring 3-7 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com