Far infrared food dryer

A far-infrared, dryer technology, applied in dryers, drying, food preservation and other directions, can solve the problems of inability to quickly dry food, high energy consumption, low production efficiency, etc., to improve the drying effect and processing. Efficiency, improve drying speed, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

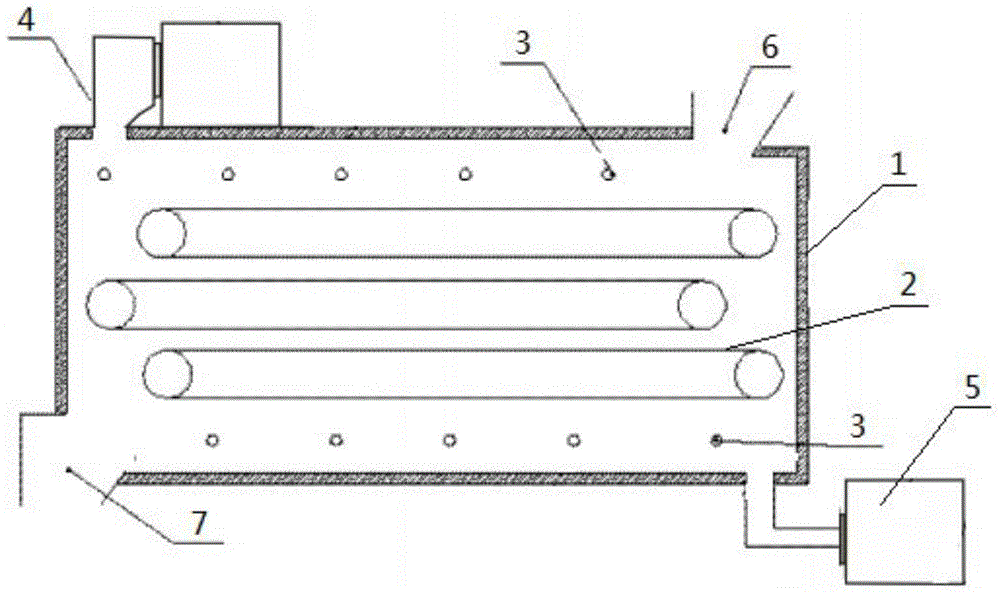

[0017] Such as figure 1 As shown, a far-infrared food dryer includes a box body 1, a conveyor belt 2, a far-infrared heating pipe 3, an aspirator 4 and a circulation fan 5, and is characterized in that: the box body 1 is a rectangular cavity structure, and the box body 1 is provided with three conveyor belts 2 from bottom to top, and the adjacent conveyor belts 2 run in opposite directions. Five far-infrared heating tubes 3 are arranged above and below the conveyor belt 2, and an aspirator 4 is connected to the left side of the top of the box body 1. The bottom of the right side of the body 1 is also connected with a circulating fan 5, and the right side of the top of the box body 1 is provided with a feed inlet 6, which is located at the starting position of the conveyor belt 2, and the left side of the bottom of the box body 1 is provided with a discharge port 7. The feed port 7 is located at the end position of the conveyor belt 2, and the box body 1 is a sandwich structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com