Spray lance for side-blown submerged combustion bath metallurgical furnace and metallurgical furnace having it

A technology for submerged combustion and metallurgical furnaces, applied in the field of metallurgical furnaces, can solve problems such as reduced production efficiency, clogging of pulverized coal channels, and inconvenient maintenance, and achieves the effect of ensuring normal operation and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

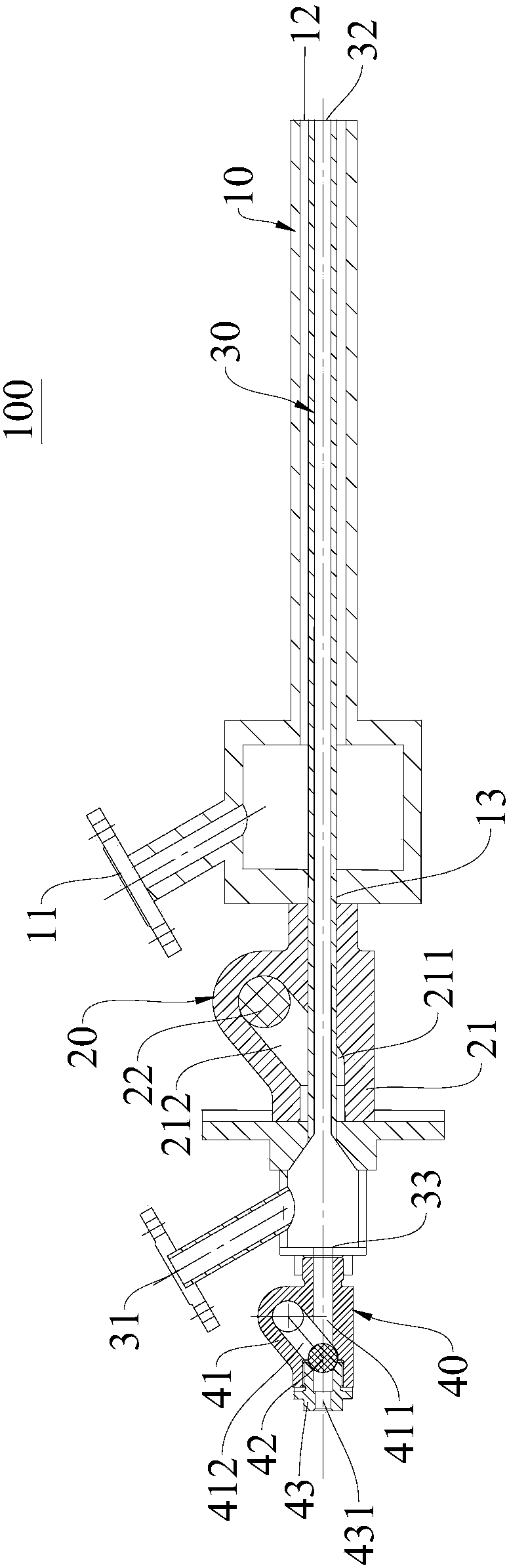

[0030] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

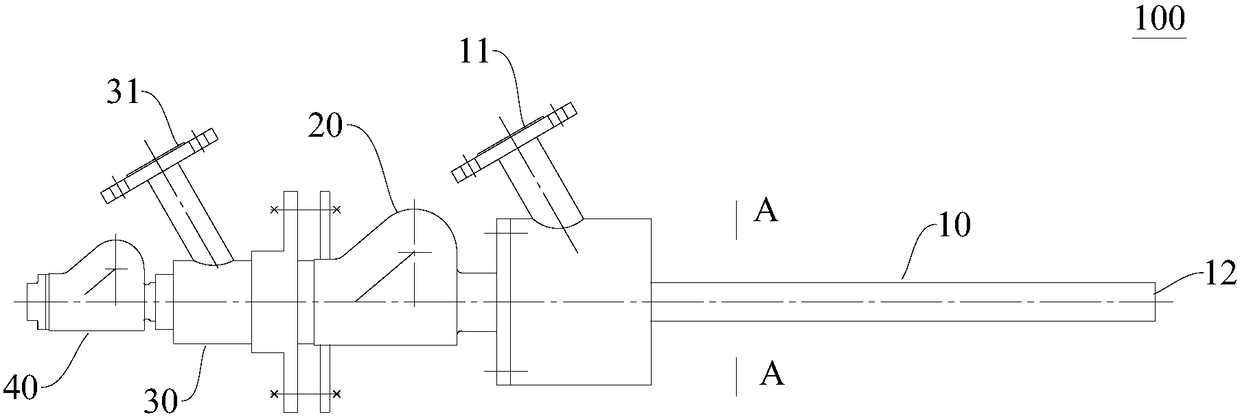

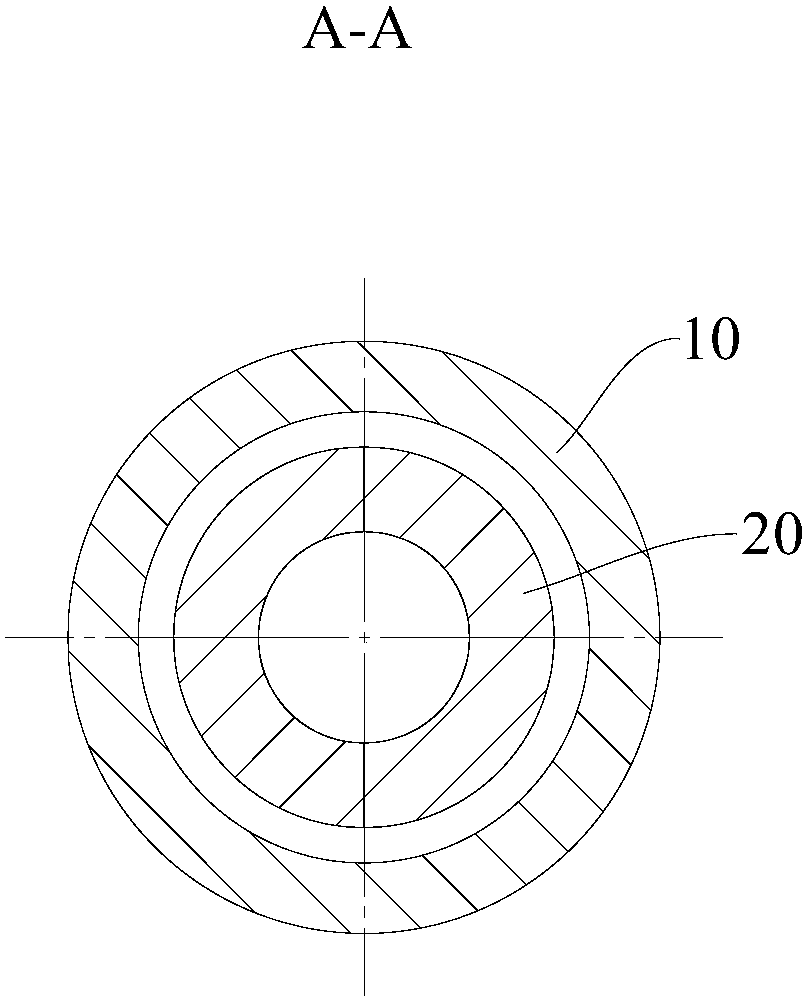

[0031] Refer below Figure 1 to Figure 4 A lance 100 for a side-blown submerged combustion bath metallurgical furnace and a metallurgical furnace 1000 having it are described in detail according to an embodiment of the present invention.

[0032] Such as figure 1 As shown, the spray gun 100 for the side-blown submerged combustion bath metallurgical furnace according to the embodiment of the first aspect of the present invention includes: an outer nozzle 10 , a plug-in self-locking part 20 , an inner nozzle 30 , and a blocking part 40 .

[0033] The outer spray pipe 10 has a gas-supporting inlet 11 , a gas-supporting outlet 12 and a socket 13 . The plug-in self...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com