Large-torque large-deflection-angle universal coupling testing stand

A universal coupling and test bench technology, which is applied in the testing of machine/structural components, machine gear/transmission mechanism testing, instruments, etc., can solve problems such as high manufacturing cost, complicated manufacturing process, and restrictions on popularization and application, and achieve operational Convenience, simple structure, and the effect of ensuring test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

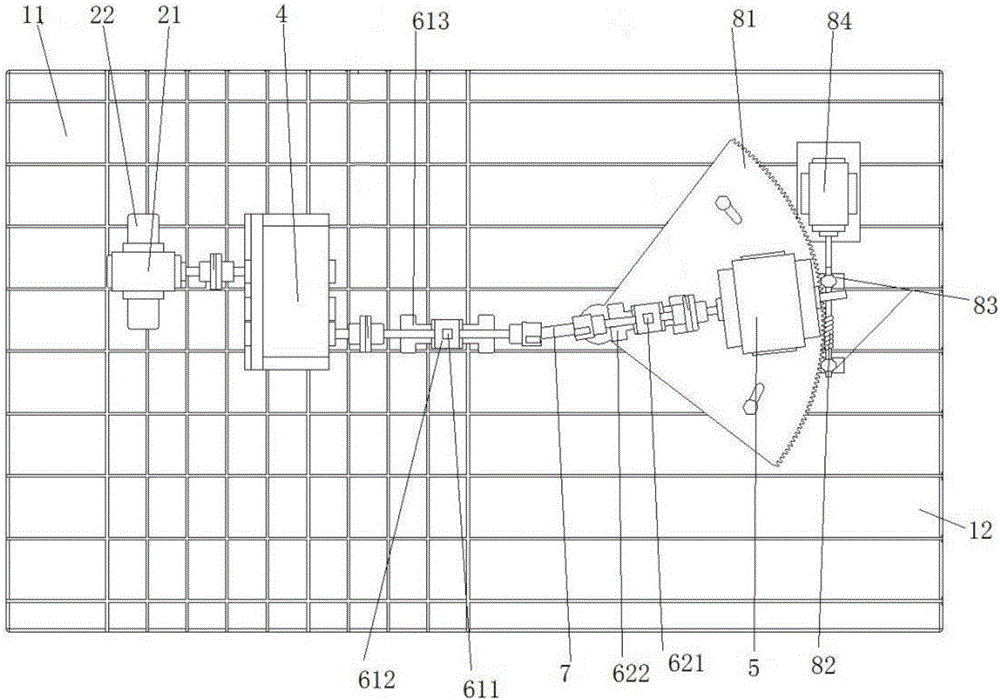

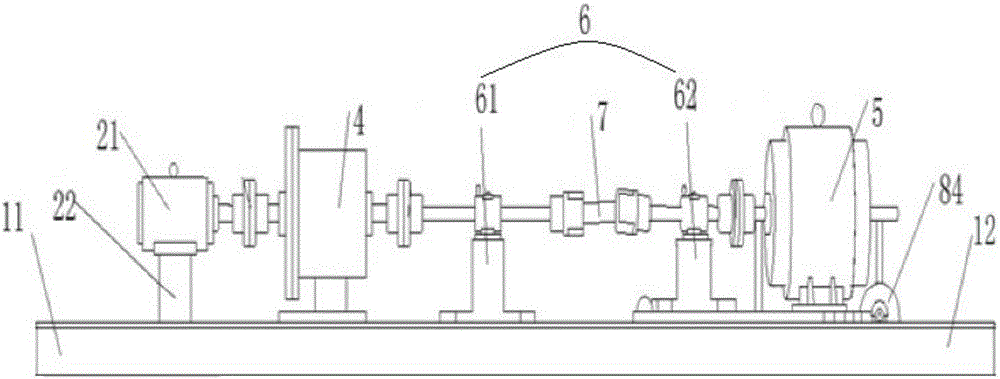

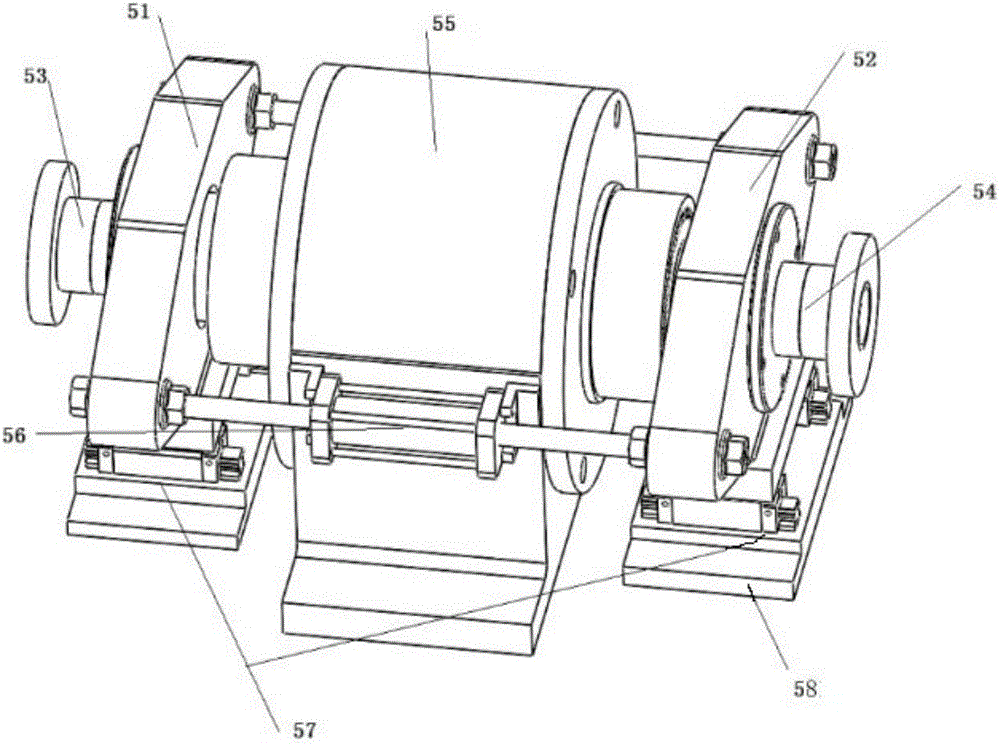

[0020] Such as figure 1 , 2 , 3, a large torque large deflection angle universal coupling test bench, including: test bench 1, power unit 2, gear box 4, universal coupling 7, torque loader 5, angle adjustment device 8. Control system; the power unit 2 is fixedly installed on the platform body of the test bench 1; the power unit 2 is connected to the input shaft of the gear box 4 through a flange; the gear box 4 The output shaft of the universal joint is connected with the input shaft of the universal joint 7 through a flange; the output shaft of the universal joint 7 is connected with the torque loader 5 through a flange; the torque loader 5 includes input support 51, connecting shaft I53, cylinder body 55, double-headed oil cylinder 56, connecting shaft II54, output support 52, slider guide rail 57, and base 58, and realizes the transmission of different large torqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com