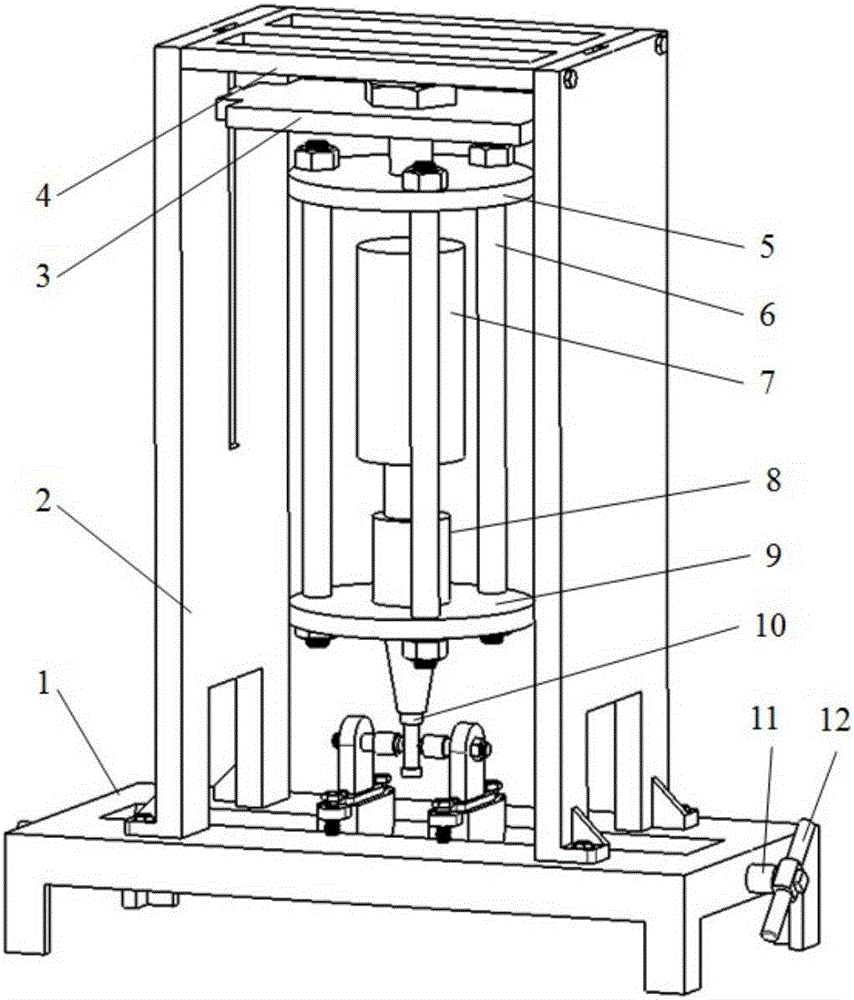

Ultrasonic high-frequency ball wear fatigue test device

A technology of fatigue test and rolling ball, which is applied in the direction of measuring device, testing wear resistance, and testing material strength by applying repetitive force/pulsation force, etc. It can solve the problem of many limiting factors in the test process, poor motor drive speed-up, and no test component fatigue Performance fatigue test equipment and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

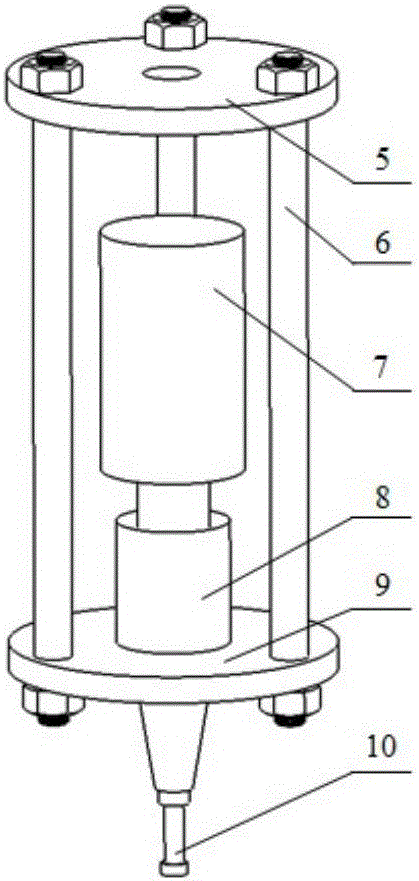

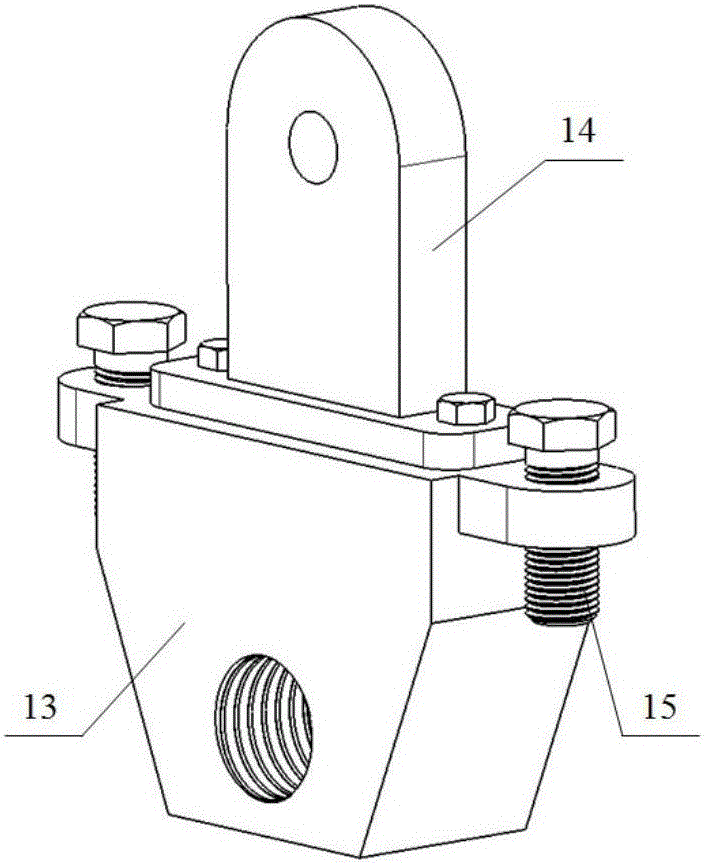

[0046] In this embodiment, when the ultrasonic high-frequency ball wear fatigue test device conducts the high-frequency wear and ultra-high cycle fatigue test of the ball sample, firstly, the ball clamping device and the ultrasonic loading device are installed on the vertical test bench respectively, and then according to the test It is required to install the ball sample 17 on the ball clamping device, and connect the ball clamping device to the ball moving device, then turn the rocking lever 12 to drive the positioning screw 11 to rotate and adjust the axial lateral position of the ball sample, and at the same time pass the slide plate 3 Adjust the longitudinal position of the ultrasonic loading device so that the ball sample 17 is in linear contact with the longitudinal vibration test piece 10 and ensure that the ball sample 17 can roll cyclically. After the position is determined, rotate the compression bolt 15 to lock and position the ball moving device. Finally, start the...

Embodiment 2

[0048] In this embodiment, when the ultrasonic high-frequency ball wear fatigue test device is used to test the ultra-high cycle fatigue performance of the longitudinal vibration test piece under the combined load of high-frequency vibration and rolling wear, a suitable vibration test piece is made according to the test material to be carried out. First, Install the ball clamping device and the ultrasonic loading device on the vertical test bench respectively, then install the ball sample 17 on the ball clamping device according to the test requirements, and connect the ball clamping device to the ball moving device, and then Rotate the rocking rod 12 to drive the positioning screw 11 to rotate and adjust the axial position of the ball sample 17, and at the same time adjust the longitudinal position of the ultrasonic loading device through the slide plate 3, so that the ball sample 17 is in linear contact with the longitudinal vibration test piece 10 and ensures that the ball sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com