An automatic control type optical fiber fusion splicer temperature adjustment device

The technology of a temperature adjustment device and an optical fiber fusion splicer is applied in the direction of optics, light guides, optical components, etc. It can solve problems such as failure to work normally and temperature influence of an optical fiber fusion splicer, and achieve the effect of compact structure, solution to failure to work normally, and easy movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

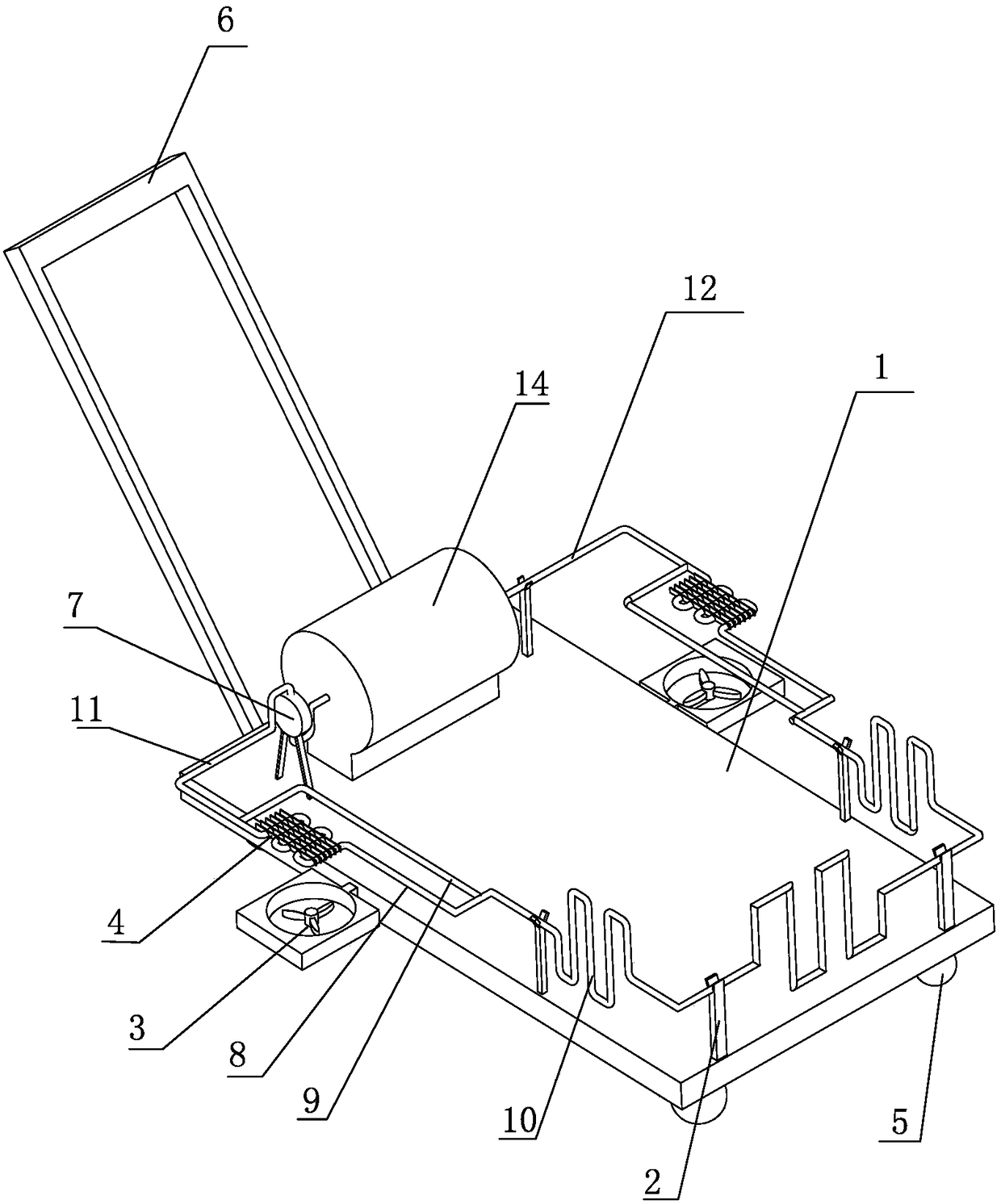

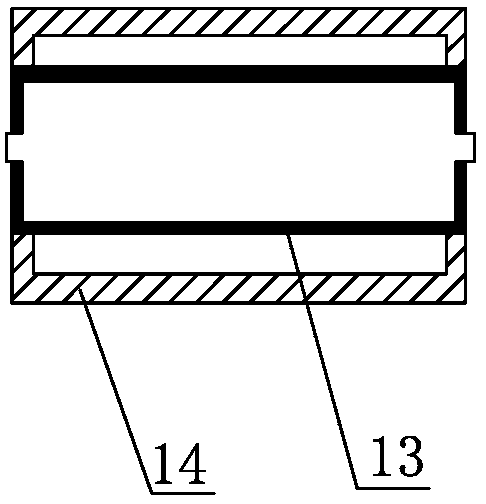

[0022] Such as Figures 1 to 2 As shown, a self-controlled optical fiber fusion splicer temperature adjustment device includes a frame, a heat dissipation device, a heating device, a thermal energy circulation system and a control system;

[0023] The frame includes a carrying plate 1 and a moving mechanism; the carrying plate 1 is mainly used for fixedly installing an optical fiber fusion splicer and fixedly connecting the device; the carrying plate 1 adopts a rectangular structure, and the surface of the carrying plate 1 An insulating layer is provided, and the insulating layer is used to prevent electric leakage during the working process of the optical fiber fusion splicer, which may cause safety accidents; the two sides of the bearing plate 1 are respectively provided with fixing plates, and the fixing plates are arranged horizontally; The plate adopts a circular structure, and the fixed plate is provided with mounting holes;

[0024] Described fixing plate and bearing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com