A mining method of c-mn steel industrial big data

A big data and data technology, applied in the field of big data mining of C-Mn steel industry, can solve problems such as increasing the amount of modeling calculations, distortion of analysis results that deviate from the facts, and unresponsive data, so as to improve regularity and accuracy performance, uniformity of training data, and the effect of reducing the amount of data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

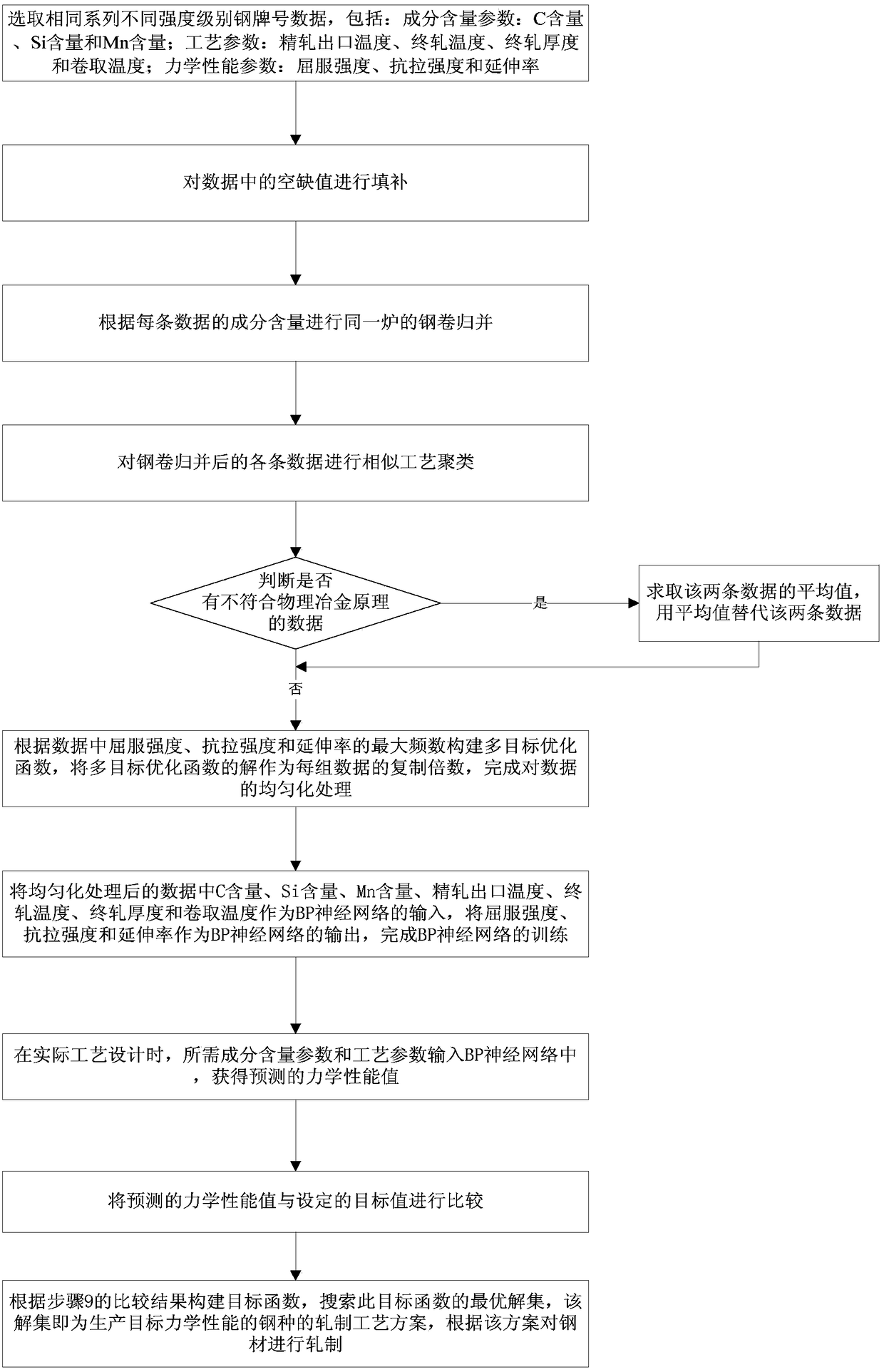

[0047] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

[0048] In the embodiment of the present invention, the mining method of C-Mn steel industrial big data, method flowchart as shown in Figure 1, comprises the following steps:

[0049] Step 1. Select the same series of steel grade data with different strength levels, including: composition content parameters: C content, Si content and Mn content; process parameters: finish rolling exit temperature, finish rolling temperature, finish rolling thickness and coiling temperature; mechanical properties Parameters: yield strength, tensile strength and elongation;

[0050] In the embodiment of the present invention, the component content must include C content, Si content, and Mn content, the process parameters must include final rolling thickness and coiling temperature, and the mechanical properties include yield strength, tensile strength and elongation; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com