Stranded composite core strain fitting for smart power grid and connection method for stranded composite core strain fitting

A technology of smart grid and tension-resistant fittings, applied in the direction of adjusting/maintaining mechanical tension, etc., can solve the problems of breaking, pulling and slipping composite cores, unable to ensure uniform force on composite cores, etc., to avoid loose grip, improve bonding force, The effect of great application value and development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

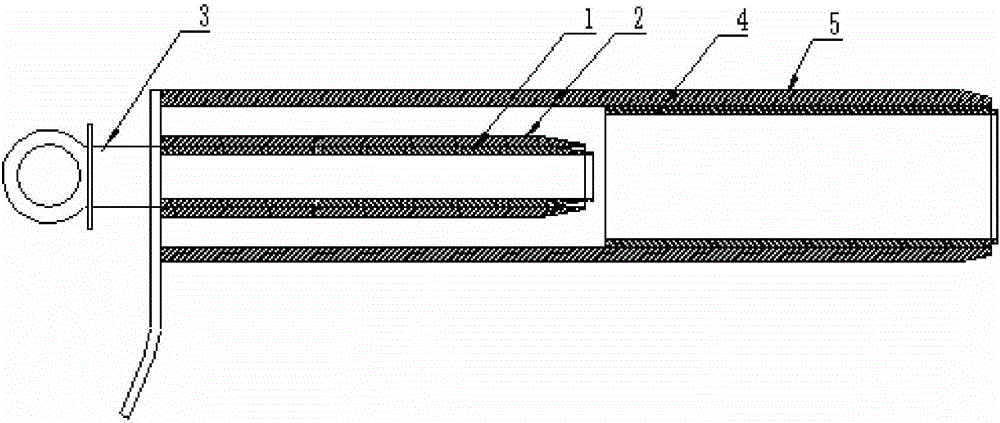

[0019] See figure 1 , the stranded composite core tensile fittings for smart grids in this embodiment include composite core lined soft aluminum tube 1, tensile steel tube 2, tensile steel anchor 3, conductor lined aluminum tube 4 and T-shaped tensile aluminum tube Tube 5; composite core-lined soft aluminum tube 1 is fully annealed soft aluminum tube with a strength of 50-80MPa and a thickness of 1.0-5.0mm. The end of the tension-resistant steel pipe 2 is provided with an internal thread, and one end of the tension-resistant steel anchor 3 is provided with a thread meshed with the tension-resistant steel pipe 2; The outer diameter is 0.1-2.0mm larger. The other end of the tension steel anchor 3 is provided with a pull ring, and a rubber gasket is provided at the pull ring. The T-shaped tensile aluminum tube 5 is a hollow tube made of heat-resistant aluminum alloy; the strength of the T-shaped tensile aluminum tube 5 is not less than 85MPa, and the elongation is not less than...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com