A capacitive cable terminal not filled with insulating medium

A technology for filling insulation and cable terminals, which is applied in the direction of cable accessories, cable installation, electrical components, etc., can solve the problems of equipment safety, breakdown, flashover or partial discharge, insulation medium leakage and other problems that threaten personal safety, and achieve improvement Pollution flashover voltage, uniform potential gradient, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

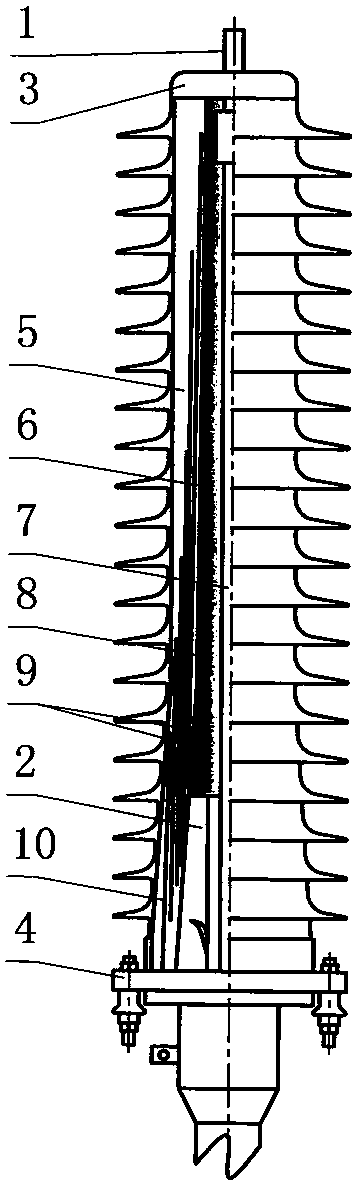

[0013] Such as figure 1 As shown, when this patent is made, the capacitive insulating sleeve 5 (for example, surrounded by epoxy glass wire) and the stress The sleeve 2 (for example, made of silicon rubber) is assembled together, the capacitive insulating sleeve 5 and the stress sleeve 2 should be tightly crimped, and the inner surface of the capacitive insulating sleeve 5 extends from the upper flange to the top surface of the stress sleeve 2 The high-voltage equipotential screen 6 (for example, laid in the insulating layer with metal foil or semi-conductive tape) and the cable conductive core 7 constitute a high-voltage equipotential chamber 8 (essentially an air cavity), and the insulation of the capacitive insulating sleeve 5 Also embedded in the layer is a group of mutually insulated capacitive screens 9 (for example, laid with metal foil or semi-conductive tape), the upper and lower edges of these capacitive screens are respectively along the outer surface of the capacit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com