Anti-delamination special coated sand and preparation method thereof

A kind of coated sand, special technology, applied in the direction of manufacturing tools, casting equipment, metal processing equipment, etc., can solve the problems of generating a large number of nitrogen holes, easy to appear burrs, easy to form layers, etc., to reduce the tendency of volume reduction, reduce The effect of resin addition and production cost control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

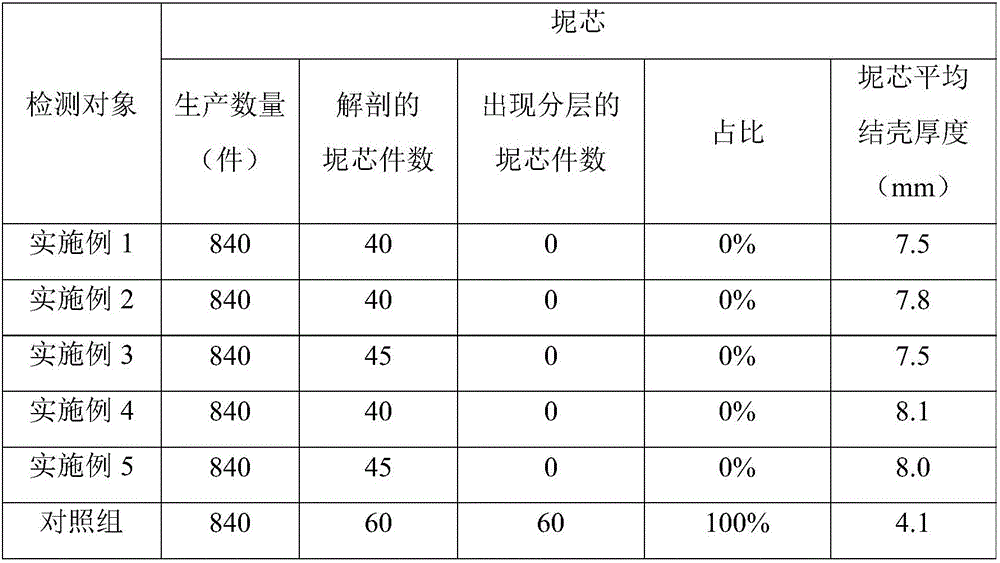

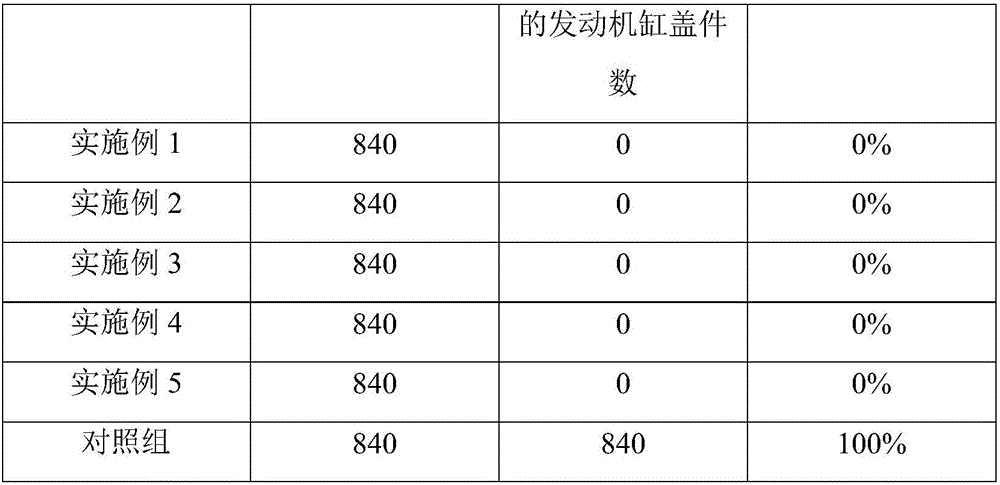

Examples

Embodiment 1

[0025] A special coated sand for anti-layering, comprising the following raw materials: original sand, phenolic resin, iron oxide, urotropine aqueous solution, calcium stearate, the original sand is composed of regenerated sand and pearl sand (used in this embodiment) Baozhu sand was purchased from Luoyang Ruiyu Fine Ceramsite Products Co., Ltd., the particle size of Baozhu sand was selected according to the surface roughness of the product), the quality of Baozhu sand accounted for 20% of the mass ratio of the original sand, and the particle size of Baozhu sand was 50 mesh, and the recycled The particle size of the sand is 50 meshes, the quality of the phenolic resin is 2.5% of the mass of the original sand, the mass of iron oxide is 0.5% of the mass of the original sand, the mass of the urotropine aqueous solution is 14% of the mass of the phenolic resin, and the mass of the urotropine is 14% of the mass of the phenolic resin. The mass ratio of urotropine to water in the aque...

Embodiment 2

[0034] A special coated sand for anti-layering, comprising the following raw materials: original sand, phenolic resin, iron oxide, urotropine aqueous solution, calcium stearate, the original sand is composed of regenerated sand and pearl sand (used in this embodiment) Baozhu sand was purchased from Luoyang Ruiyu Fine Ceramsite Products Co., Ltd., the particle size of Baozhu sand was selected according to the surface roughness of the product), the quality of Baozhu sand accounted for 21% of the mass ratio of the original sand, and the particle size of Baozhu sand was 60 mesh. The particle size of the sand is 60 meshes, the quality of the phenolic resin is 2.6% of the mass of the original sand, the mass of iron oxide is 0.5% of the mass of the original sand, the mass of the urotropine aqueous solution is 15% of the mass of the phenolic resin, and the mass of the urotropine is 15% of the mass of the phenolic resin. The mass ratio of urotropine to water in the aqueous solution is 1...

Embodiment 3

[0043] A special coated sand for anti-layering, comprising the following raw materials: original sand, phenolic resin, iron oxide, urotropine aqueous solution, calcium stearate, the original sand is composed of regenerated sand and pearl sand (used in this embodiment) Baozhu sand was purchased from Luoyang Ruiyu Fine Ceramsite Products Co., Ltd., the particle size of Baozhu sand was selected according to the surface roughness of the product), the quality of Baozhu sand accounted for 22% of the mass ratio of the original sand, and the particle size of Baozhu sand was 75 mesh. The particle size of the sand is 65 meshes, the quality of the phenolic resin is 2.6% of the mass of the original sand, the mass of iron oxide is 0.7% of the mass of the original sand, the mass of the urotropine aqueous solution is 15% of the mass of the phenolic resin, and the mass of the urotropine is 15% of the mass of the phenolic resin. The mass ratio of urotropine to water in the aqueous solution is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com