Integrated valve set control system

A technology of control system and integrated valve group, which is applied in pipeline system, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problem of increasing the cost of production, disassembly, maintenance and overhaul of integrated valve group control system, which cannot be achieved by individual valves Disassembly and assembly processing, each valve cannot be disassembled and replaced independently, etc., to achieve the effect of convenient and simple disassembly and maintenance, reduce production and maintenance costs, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

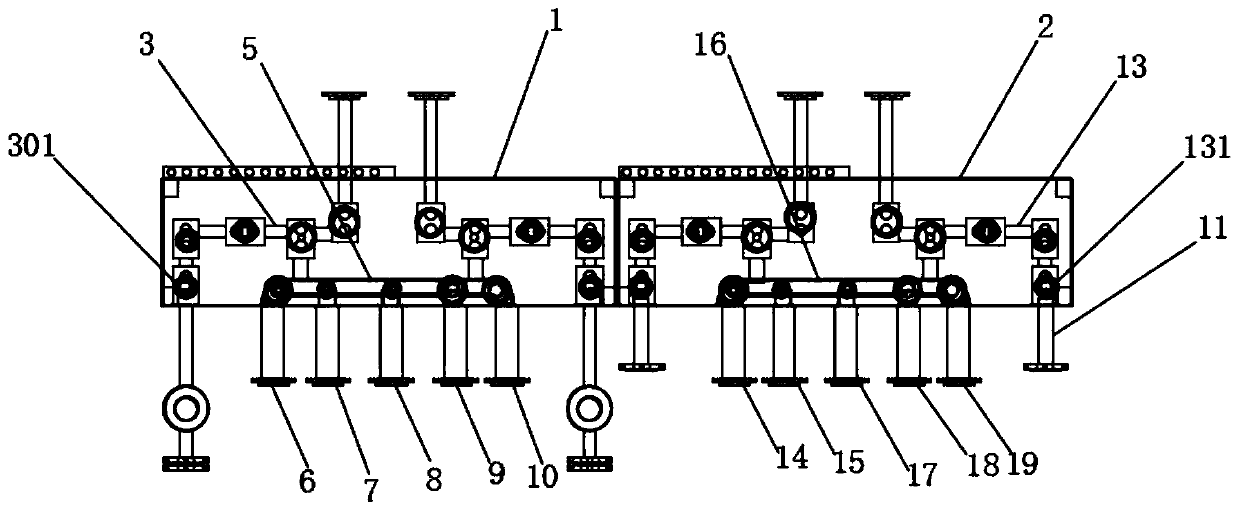

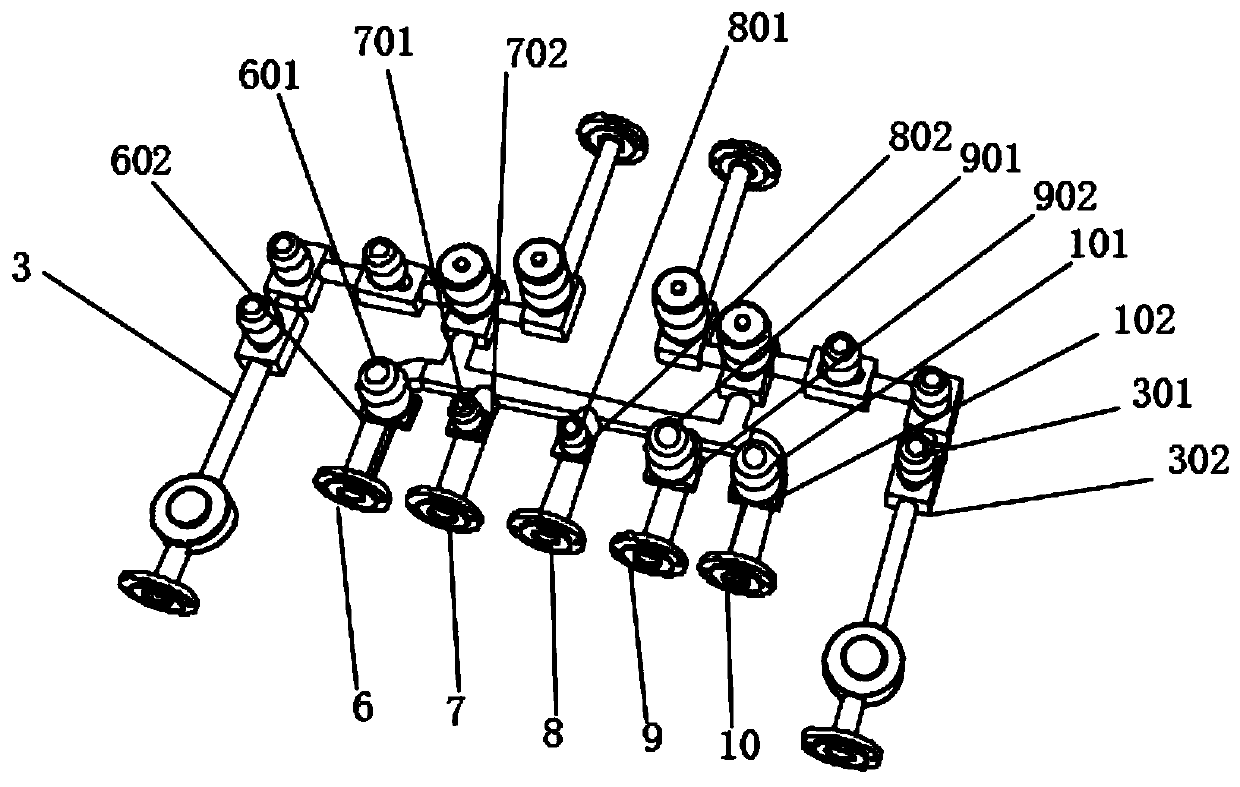

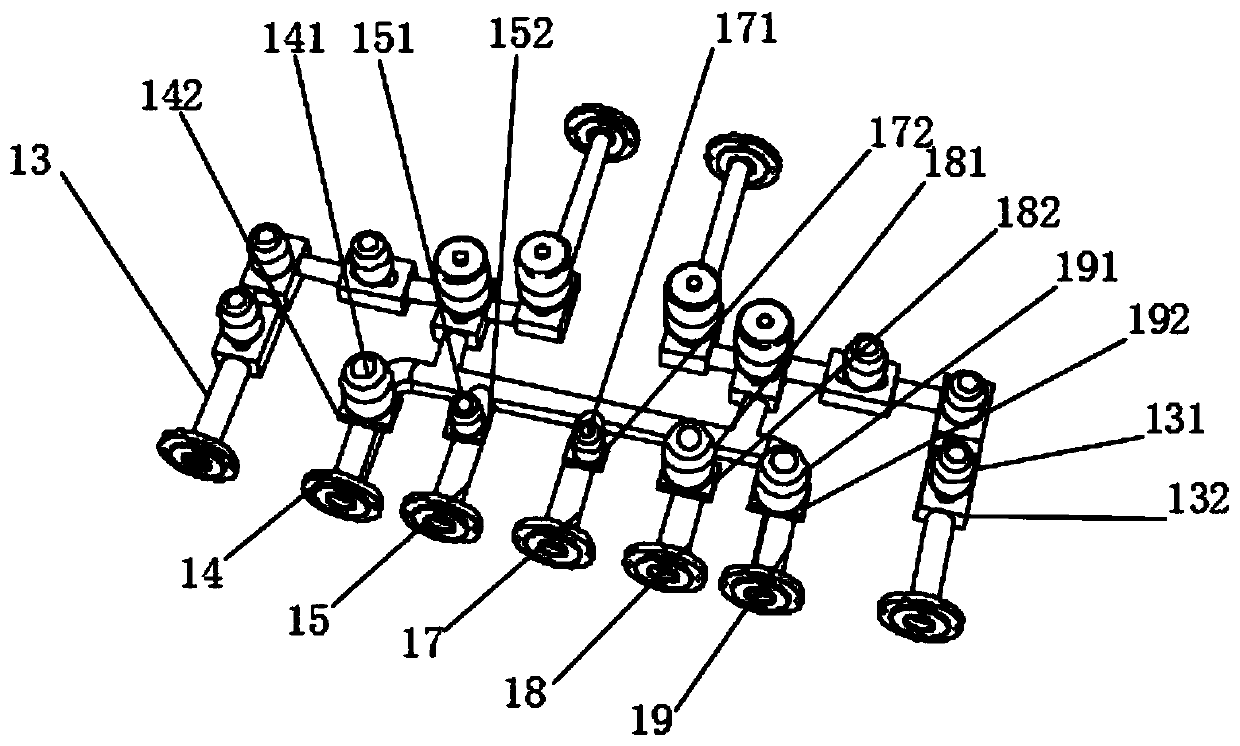

[0020] see Figure 1~4 , in an embodiment of the present invention, an integrated valve group control system includes a first external heat preservation box 1 and a second external heat insulation box 2 arranged on one side of the first external heat preservation box 1, the first external heat insulation box The inside of 1 is fixedly provided with a first connecting main pipe 5, and the side of the first connecting main pipe 5 is symmetrically fixedly provided with two shaped air intake pipes 3, and the side of the shaped air intake pipe 3 is fixedly provided with a shaped air intake valve block 302, and the shaped air intake valve A bottom-in-bottom-out control valve 301 is fixedly installed on the side of the block 302, a first main row connecting pipe 6 is fixedly installed at one end of the first connecting main pipe 5, and a first main row valve block is fixedly installed on the side of the first main row connecting pipe 6 602, the other end of the first communicating ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com