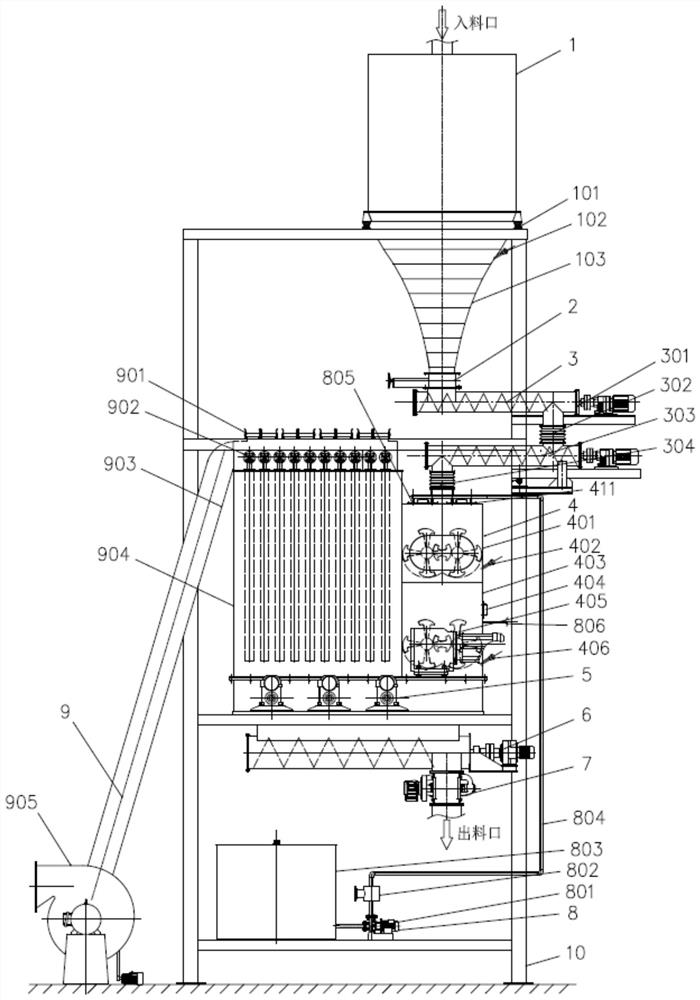

Modular high-temperature material digestion system

A technology for high-temperature materials and digestion systems, applied in chemical instruments and methods, gas treatment, dispersed particle separation, etc., can solve the problems of equipment corrosion, heat loss, increase the operating cost of cement plants, etc., to achieve simple operation control and control of production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] The high-temperature material at 200-250°C is used for digestion. The material enters the raw material bin 1 from the center of the top. The group seat of the raw material bin 1 is fixed by bolts and three weighing modules 101 uniformly distributed in the circumferential direction, and the other end of the weighing module 101 is fixed by bolts. Fixed on the structural frame 10, the material enters the raw material warehouse, the volume of the raw material warehouse is 3-5m 3It has the function of material storage and buffering, and controls the material level at a certain height according to the program control requirements. A temperature sensor is installed at 1 / 4 of the hyperbolic cone of the raw material silo to detect and feed back the temperature of the incoming material; a weighing sensor is installed under the support group of the silo to monitor and feedback the material level in the silo; the silo cone is a hyperbolic structure.

[0027] A gate valve is set und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com