Motor vehicle aluminum alloy wheel hub retreading repair method

A technology of aluminum alloy wheels and aluminum alloys, which is applied in the direction of pretreatment surface, device for coating liquid on the surface, coating, etc., can solve the problems that cannot be restored to the state when it leaves the factory, so as to improve the surface hardness and adhesion, and save resources , the effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

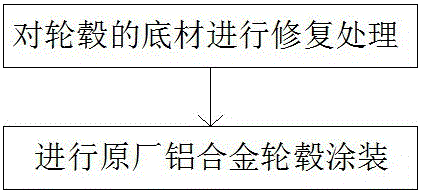

[0024] Please see attached figure 1 As shown, a method for refurbishing and repairing an aluminum alloy wheel hub of a motor vehicle, the method at least includes the following steps:

[0025] Step 1: Repair the base material of the hub.

[0026] Step 2: Paint the original factory aluminum alloy wheels.

[0027] In said step 1, the following sub-steps are also included:

[0028] Step 1.1: According to the defects of the wheel hub, remove the old coating on the overall aluminum alloy wheel hub, and use the special water-based paint remover for the original high-temperature paint to remove the old coating. Carry out grinding treatment, and then carry out deoxidization treatment, degreasing and degreasing treatment, passivation treatment and cleaning and drying on the defective parts of the aluminum alloy wheel hub.

[0029] Step 1.2: Use aluminum alloy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com