Dedusting tablet press

A tablet press, tablet press technology, applied in the direction of presses, dust removal, material forming presses, etc., can solve the problems of dust flying, low efficiency, secondary pollution, etc., to simplify the production process, shorten the processing cycle, Increase the effect of safety and hygiene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

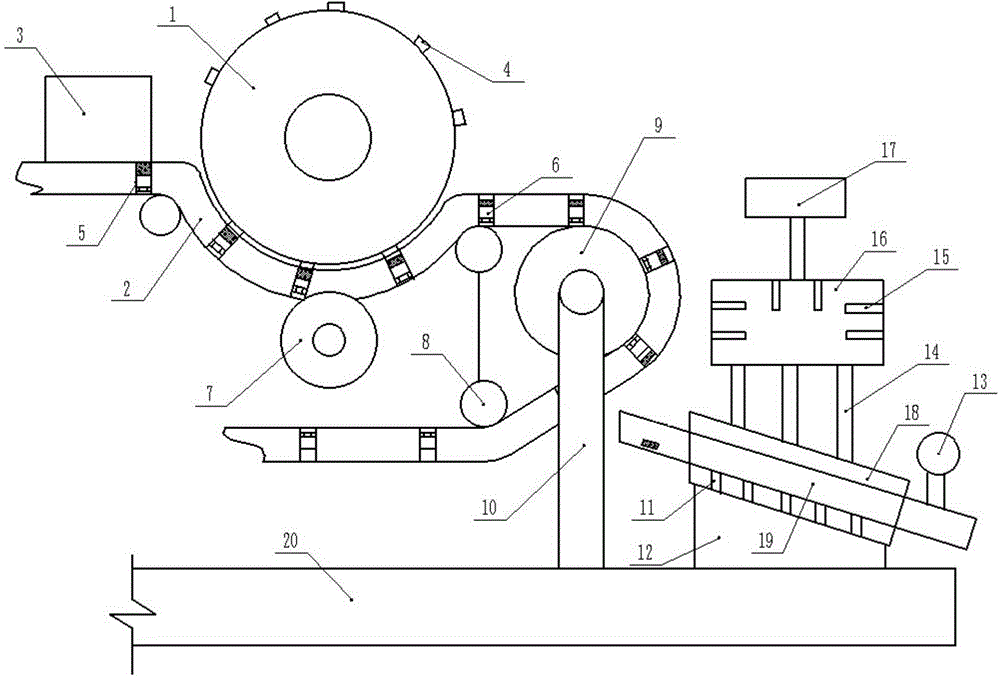

[0012] see figure 1 , a dust-removing tablet press machine, comprising a tablet roller 1, a chute 19 and a base 20, the lower end of the tablet roller 1 is provided with a small tablet lifting roller 7, and the tablet roller 1 and the small tablet lifting roller 7 is clamped with a transmission belt 2, the upper surface of the transmission belt 2 is attached to the lower surface of the tablet roller 1, the left side of the tablet roller 1 is provided with a powder filling device 3, and the outer wall of the tablet roller 1 is provided with several A tabletting upper mold column 4, several tableting grooves 5 are arranged in the transmission belt 2, the tableting groove 5 is internally movably clamped with a tableting lower mold column 6, and the tableting upper mold column 4 and the tableting groove 5 are used in cooperation; In addition, the righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com