Material handling robot

A technology for handling robots and materials, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of large space occupation, high labor costs, low efficiency, etc., to save manpower and material resources, save storage space, take quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

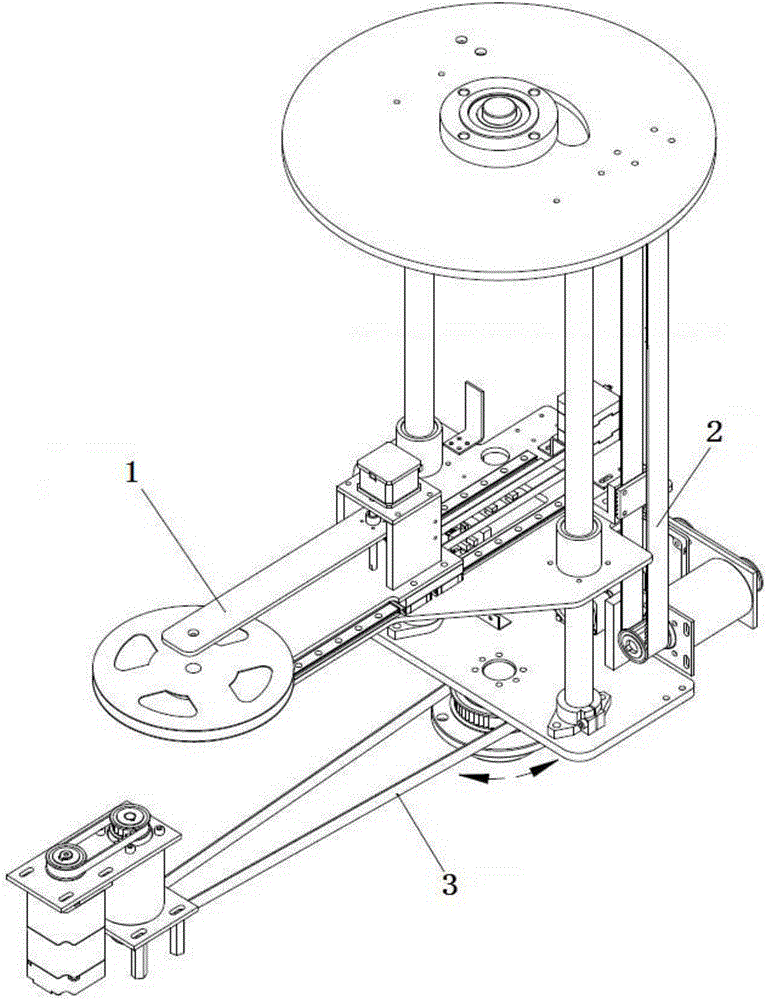

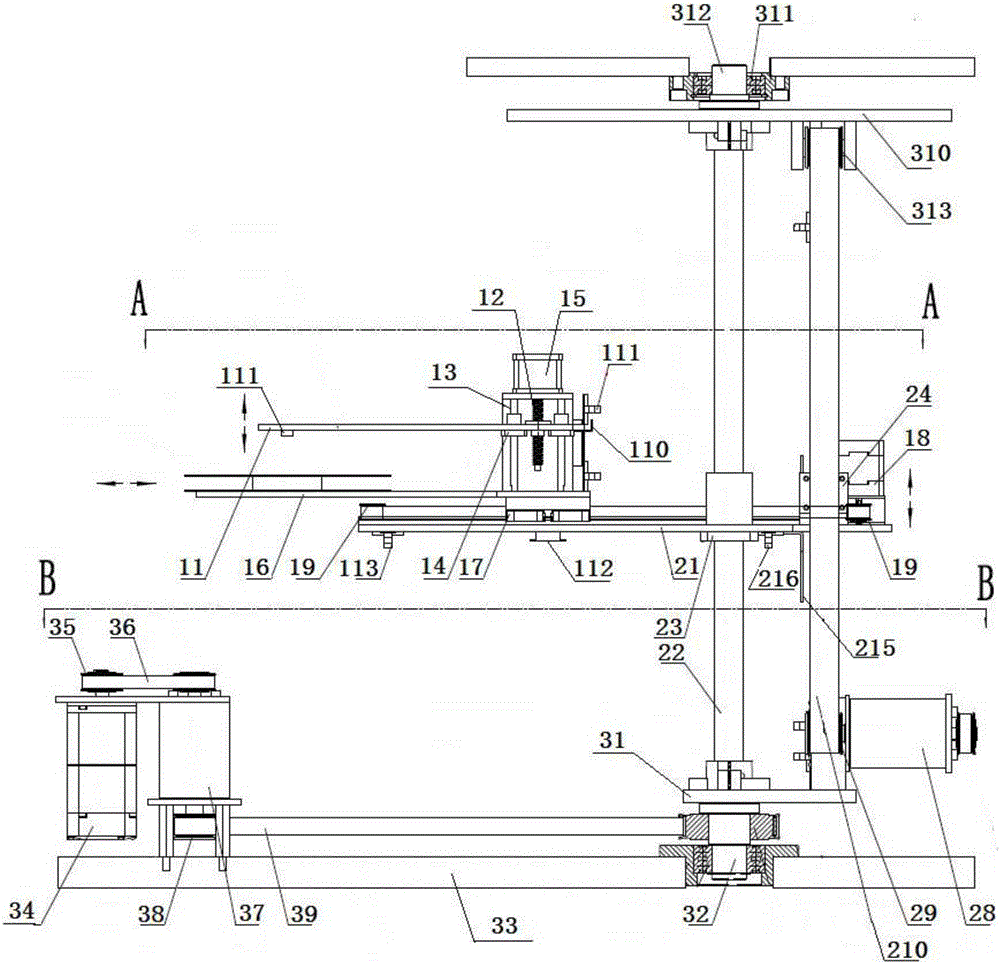

[0025] Such as figure 1 As shown, the present invention discloses a material handling robot, comprising a gripping device 1, a lifting device 2 and a rotating device 3, the lifting device 2 is installed on the rotating device 3, the gripping device 1 is installed on the lifting device 2, and the material handling The robot also includes a PLC control system, the PLC control system controls the lifting of the lifting device 2, the PLC control system controls the rotating device 3 to rotate in three-dimensional space, and the PLC control system controls the clamping device 1 to achieve material clamping and forward and backward movement.

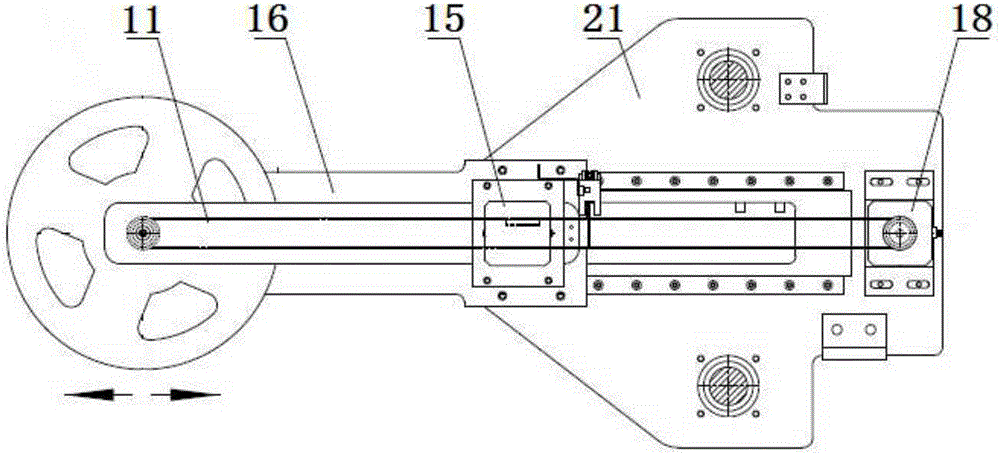

[0026] Such as Figures 2 to 3 As shown, the clamping device 1 includes a clamping splint 11, a screw nut 12, a first guide mandrel 13, a first linear bearing 14, a linear stepper motor 15, a clamping substrate 16, a linear slide rail 17, a stepper The motor 18 and the first synchronous pulley 19, the clamping splint 11 is installed on the sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com