Biological excess sludge deep dehydration conditioner

A technology of excess sludge and deep dewatering, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problem of large dosage of chemical conditioning sludge conditioner, loss of calorific value of sludge organic matter, and unfavorable excess sludge incineration. and other problems, to achieve the effect of self-sustained incineration, enhanced sludge dewatering performance, and enhanced dewatering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

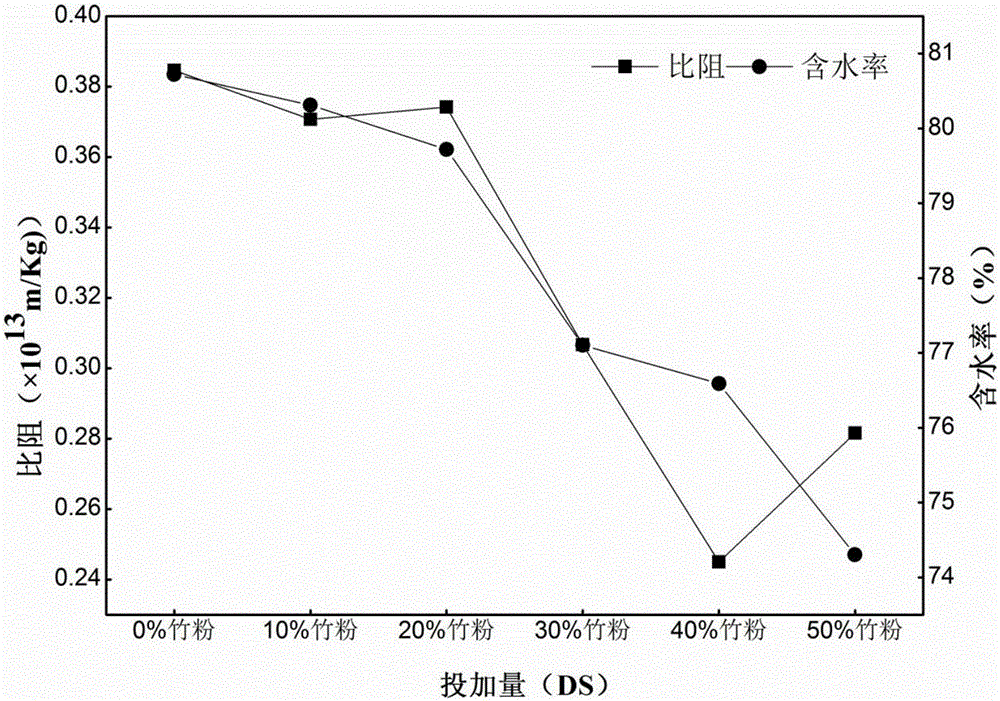

[0043] Sludge dewatering effect under different bamboo powder dosage conditions of embodiment 1

[0044] Get agricultural waste bamboo powder (particle diameter is lower than 100 orders) respectively, add by dry sludge mass ratio 0%, 10%, 20%, 30%, 40% and 50%, as sludge dehydration conditioning agent, and After the sludge is stirred and mixed, the sludge is deeply dehydrated.

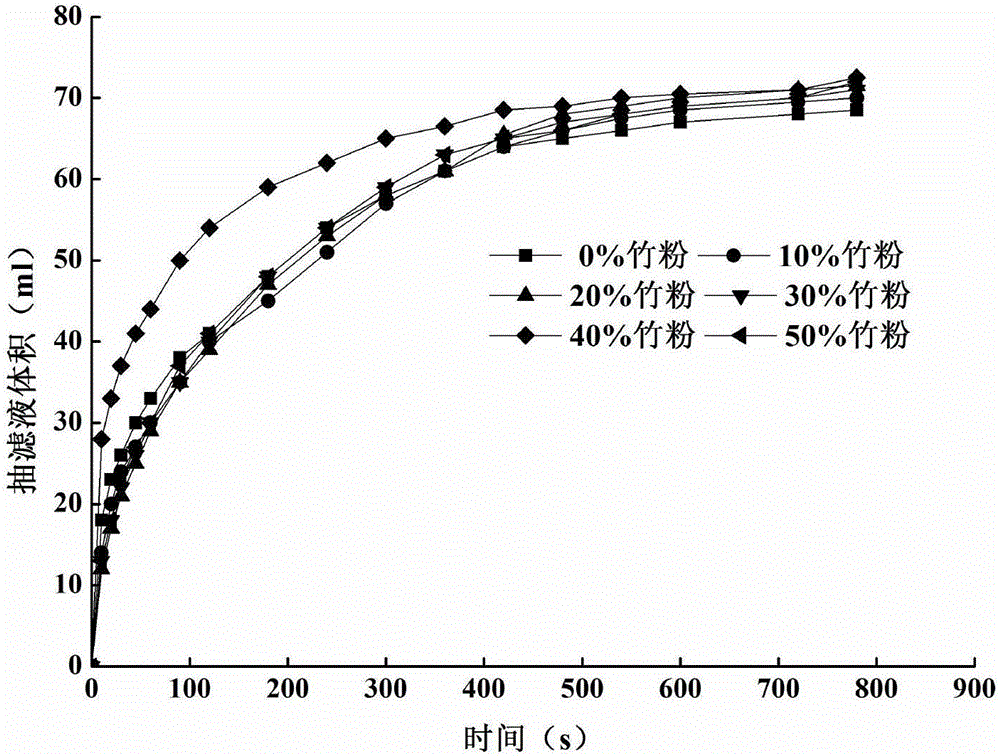

[0045] 1. Sludge dehydration rate

[0046] When using bamboo powder as a sludge conditioner to condition sludge, different dosages of bamboo powder have different effects on sludge filtration rate and filtrate volume, as shown in figure 1 shown. from figure 1 It can be seen that compared with no bamboo powder, the sludge yield rate and filtrate volume after bamboo powder conditioning were slightly increased, and the effect was more obvious at 40% dosage. The pumping time is reduced by an average of 60-300s. This is because the skeleton support structure of bamboo powder increases the sludge floc an...

Embodiment 2

[0053] Sludge dewatering effect when embodiment 2 bamboo powder is coupled with PAM

[0054] PAM dosage ratio is 0.3%, get agricultural waste bamboo powder (particle size is lower than 100 orders) respectively, add by dry sludge mass ratio 0%, 10%, 20%, 30%, 40% and 50%, Coupled with PAM as a sludge dehydration conditioner, the sludge is deeply dehydrated.

[0055] 1. Sludge dehydration rate

[0056] When bamboo powder and 0.3% PAM are used as sludge conditioners to condition sludge, different dosages of bamboo powder have different effects on sludge filtration rate, such as Figure 5 shown. It can be seen from the figure that the difference in suction filtration rate and filtrate volume is small when adding different amounts of bamboo powder, but when the addition ratio of bamboo powder is 30% and 50%, the filtrate volume and suction filtration rate are larger ; When the addition ratio of bamboo powder is 30%, compared with single addition, the suction filtration time is r...

Embodiment 3

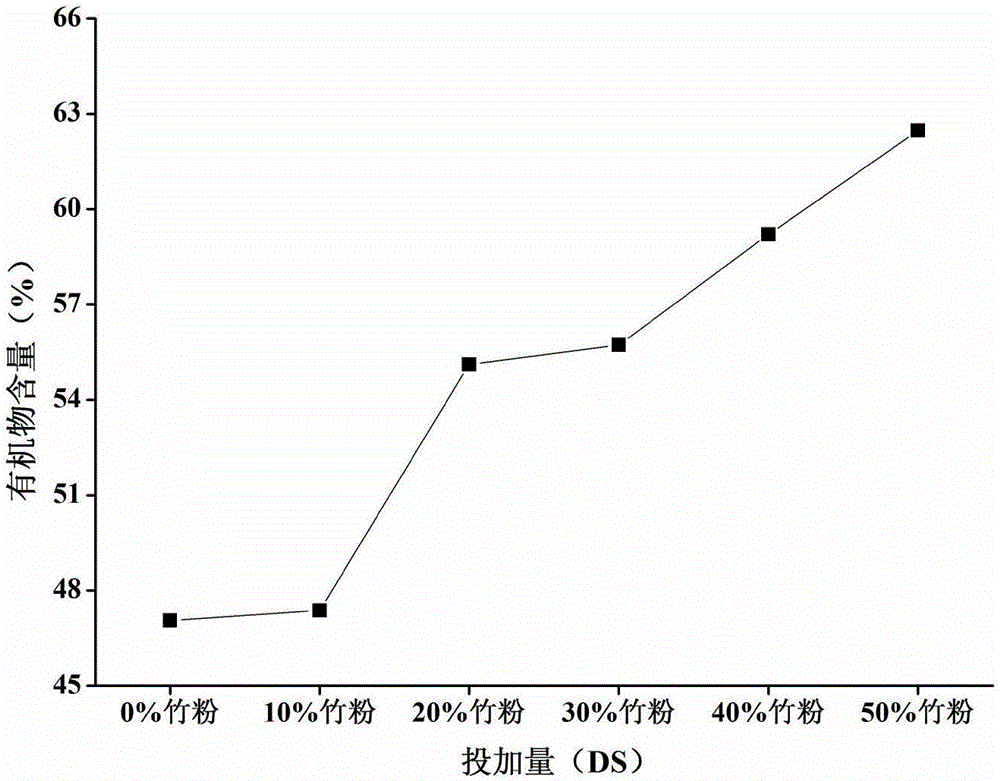

[0061] Example 3 Bamboo powder, sludge dry basis calorific value comparison after conditioning

[0062] Figure 8 The effects of different dosages of lime and bamboo powder on the calorific value of conditioned sludge on dry basis were described. from Figure 8 It can be seen from the figure that with the increase of CaO dosage, the sludge wall is broken under the action of high temperature (80°C) and high pH (11-12), and a large amount of organic matter is transferred to the liquid phase, and its calorific value increases accordingly. reduce. When the dosage is 50%, its calorific value drops by about 33%, only 6793kJ / kg. Although the use of CaO can reduce the moisture content of the sludge, it is not suitable to use CaO for dehydration.

[0063] When bamboo powder is added, the calorific value of the sludge increases gradually. On the one hand, because bamboo powder is organic matter, adding it will increase the calorific value. The microbial cell structure of sludge make...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap