Preparation method of attapulgite-carbon nitride-polyaniline composite material and application thereof in anticorrosive paint

A technology of attapulgite and composite materials, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problem of unsatisfactory mechanical properties of comprehensive performance of anti-corrosion coatings, restricting the popularization and application of polyaniline, dispersibility and adhesion problems such as poor performance, to achieve excellent physical barrier effect, low production cost, and the effect of preventing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

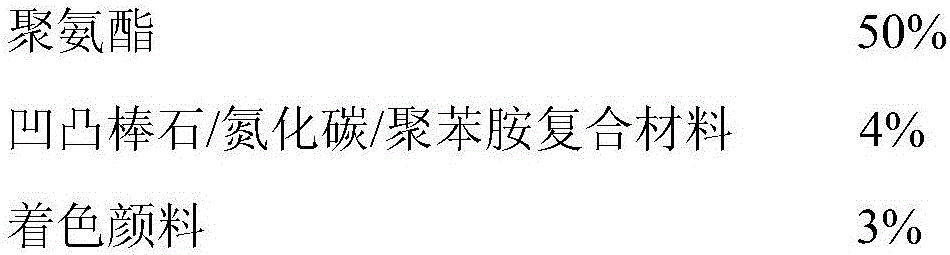

[0020] Proportioning each component according to the following mass percentages:

[0021]

[0022]

[0023] Wherein, the preparation method of above-mentioned attapulgite / carbon nitride / polyaniline composite material is:

[0024] (1) Prepare a dispersion containing aniline and graphite phase carbon nitride, wherein the concentration of aniline is 0.3 mol / L, and the concentration of carbon nitride is 10 mg / mL, stir well and pre-cool to 0°C;

[0025] (2) Prepare ammonium persulfate aqueous solution and pre-cool to 0°C, wherein the concentration of ammonium persulfate is 0.3mol / L;

[0026] (3) Fully disperse attapulgite in deionized water to prepare a slurry with a mass concentration of 3g / 100mL, add the dispersion obtained in step (1) to the slurry, stir evenly, and then Next, add the ammonium persulfate aqueous solution obtained in step (2), react at 0°C for 4 hours, filter, wash, dry and grind to 150 mesh to prepare the attapulgite / carbon nitride / polyaniline composite m...

Embodiment 2

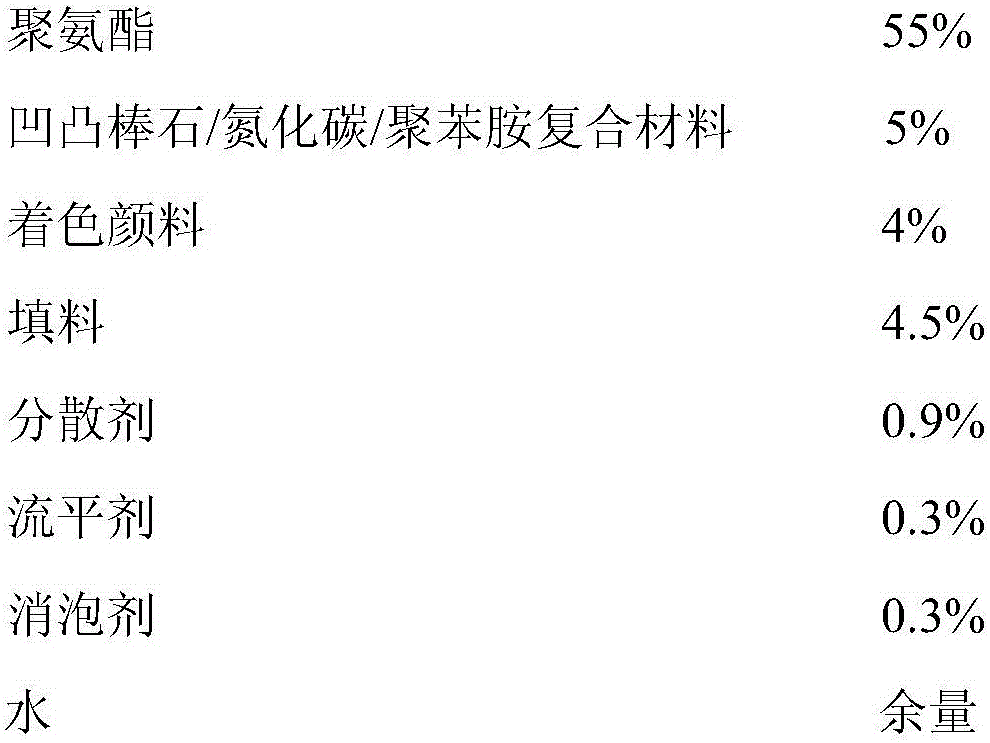

[0030] Proportioning each component according to the following mass percentages:

[0031]

[0032] Wherein, the preparation method of above-mentioned attapulgite / carbon nitride / polyaniline composite material is:

[0033] (1) Prepare a dispersion containing aniline and graphite phase carbon nitride, wherein the concentration of aniline is 0.35 mol / L, and the concentration of carbon nitride is 20 mg / mL, stir well and pre-cool to 0°C;

[0034] (2) Prepare ammonium persulfate aqueous solution and pre-cool to 0°C, wherein the concentration of ammonium persulfate is 0.35mol / L;

[0035] (3) Fully disperse attapulgite in deionized water to prepare a slurry with a mass concentration of 3.5g / 100mL, add the dispersion obtained in step (1) to the slurry, stir evenly, and then stir state, add the ammonium persulfate aqueous solution obtained in step (2), react at 0°C for 4h, filter, wash, dry and grind to 200 mesh, and obtain the attapulgite / carbon nitride / polyaniline composite materia...

Embodiment 3

[0039] Proportioning each component according to the following mass percentages:

[0040]

[0041] Wherein, the preparation method of above-mentioned attapulgite / carbon nitride / polyaniline composite material is:

[0042] (1) Prepare a dispersion containing aniline and graphite phase carbon nitride, wherein the concentration of aniline is 0.4 mol / L, and the concentration of carbon nitride is 30 mg / mL, stir well and pre-cool to 1 °C;

[0043] (2) Prepare ammonium persulfate aqueous solution and pre-cool to 1°C, wherein the concentration of ammonium persulfate is 0.4mol / L;

[0044] (3) Fully disperse attapulgite in deionized water to prepare a slurry with a mass concentration of 4g / 100mL, add the dispersion obtained in step (1) to the slurry, stir evenly, and then Next, add the aqueous solution of ammonium persulfate obtained in step (2), react at 1°C for 4 hours, filter, wash, dry and grind to 250 mesh to prepare the attapulgite / carbon nitride / polyaniline composite material,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com