Method of manufacturing engine crankshaft and laser shock reinforcing device of engine crankshaft

A manufacturing method and laser shock technology, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems of difficult to guarantee laser strengthening, labor and time-consuming, high fixture manufacturing cost, and achieve increased hardness, increased service life, and improved impact toughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

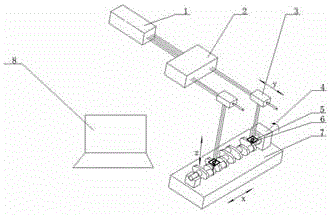

[0021] The technical solution of the present invention will be described in more detail below in conjunction with the accompanying drawings.

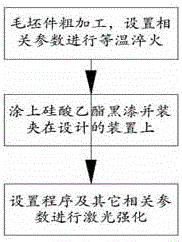

[0022] Such as figure 1 As shown, the engine crankshaft processing process is: ductile iron blank → rough machining → austempering treatment → laser shock surface strengthening → finishing → finished crankshaft. Specifically: Step 1: Roughly process the nodular cast iron blank of the crankshaft to form the crankshaft primary product; Step 2: Perform austempering on the crankshaft primary product; Step 3: Perform laser shock surface strengthening on the crankshaft primary product after austempering Processing; Step 4: Finishing the primary crankshaft after the laser shock surface strengthening treatment, and finally forming the finished crankshaft.

[0023] Preferably, after the rough machining of the crankshaft, put it into an overturning trolley-type quenching furnace and heat it to 850±20°C, keep it warm for 90 minutes, and then leav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com