Auxiliary electric motor special for wind power, bearing grease adding method of electric motor and wind power unit

A technology for auxiliary motors and electric motors, applied in the direction of electric components, engines, bearing components, etc., can solve the problems of small motor suppliers being overwhelmed, achieve the effects of reducing maintenance burden, improving reliability, and ensuring reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

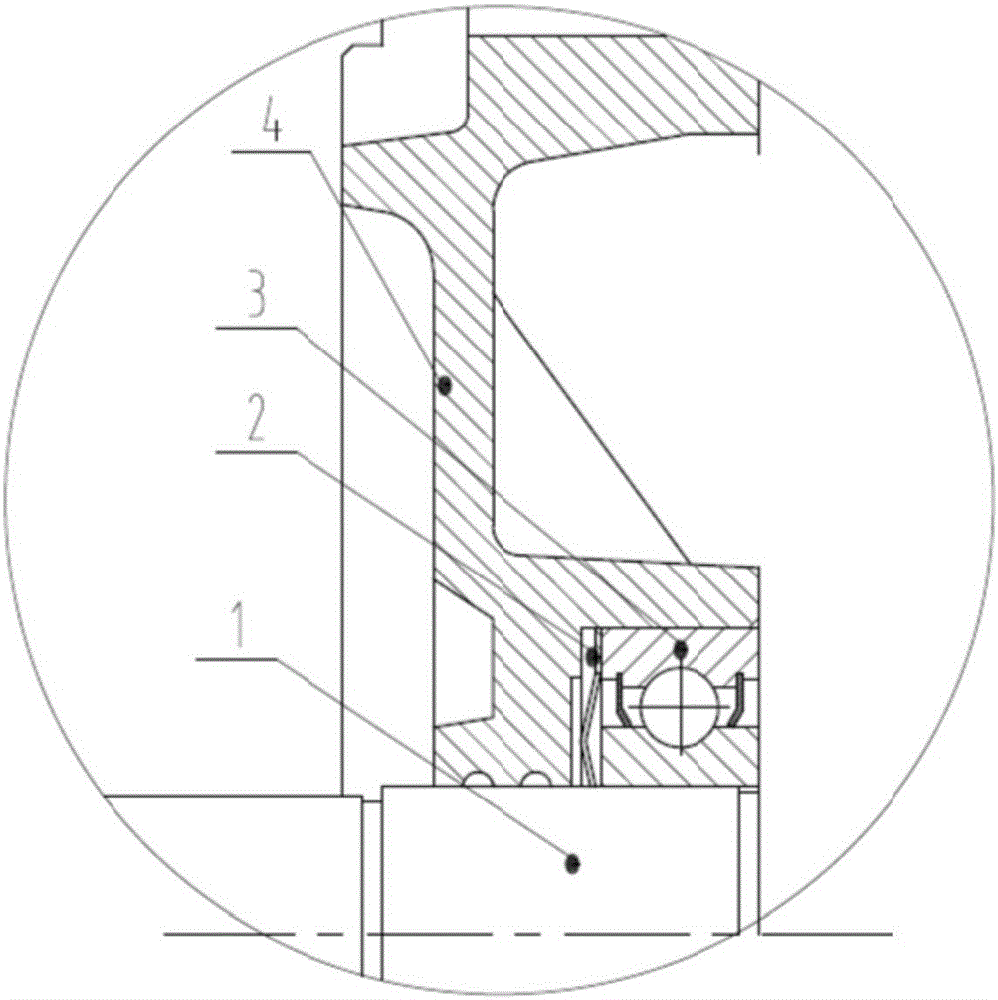

[0030] Such as figure 1 As shown, the existing conventional wind power auxiliary motor includes a rotating shaft 1 , a wave gasket 2 , a sealed bearing 3 , and an end cover 4 . The sealed bearing 3 is set on the outer circle of the rotating shaft 1, the inner diameter of the sealed bearing 3 is an interference fit with the outer diameter of the rotating shaft 1, and the end cover 4 is set on the outer circle of the sealed bearing 3, between the sealed bearing 3 and the end cover 4 Between them, there is a wave washer 2 for adjusting the axial clearance of the sealed bearing 3 .

[0031] With reference to the bearing structure of conventional small asynchronous motors, this kind of bearing structure uses disposable sealed bearings. There are no grease filling and grease discharge channels on the end cover, and there is no bearing inner cover and bearing outer cover for axial positioning in the axial direction of the bearing, resulting in In the harsh operating environment of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com