Retarder, agitator and agitating lorry

A technology of reducer and power input end, which is applied in the field of agitating transport tank trucks. It can solve the problem that the reducer cannot adapt to the normal transmission of the axis of rotation and the axis of rotation of the reducer. It achieves the effect of reducing maintenance costs and facilitating operation and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

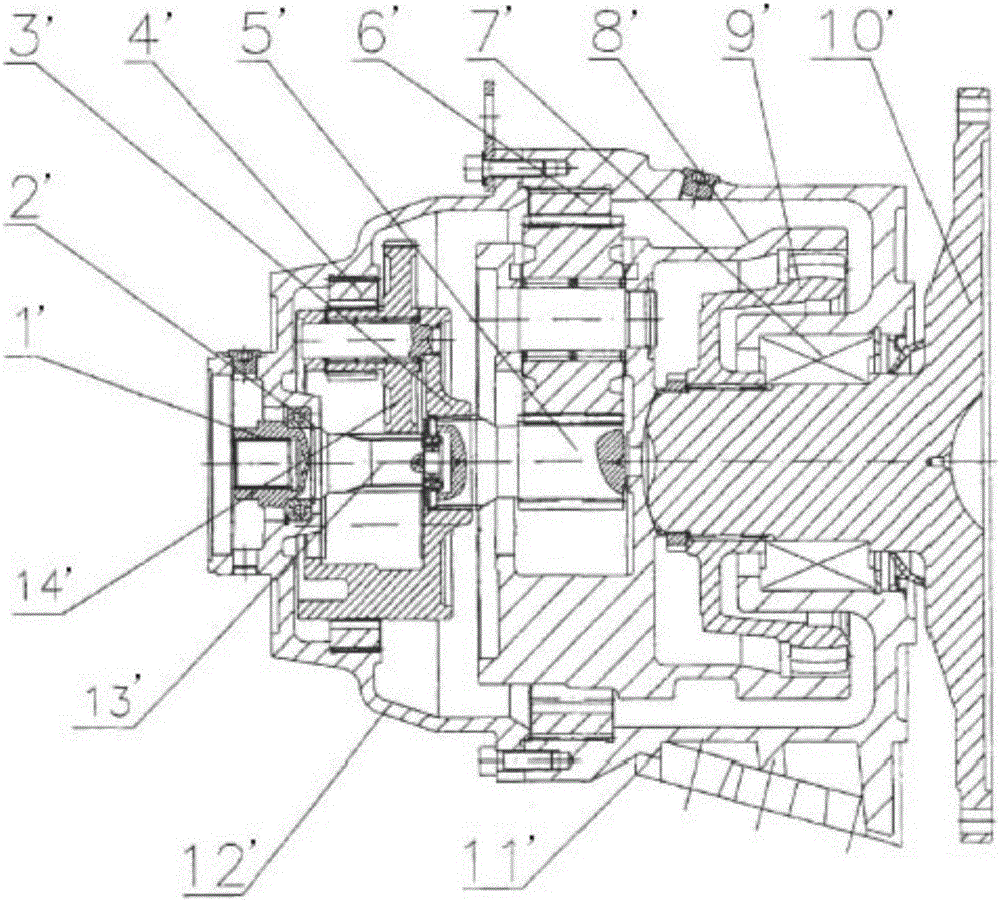

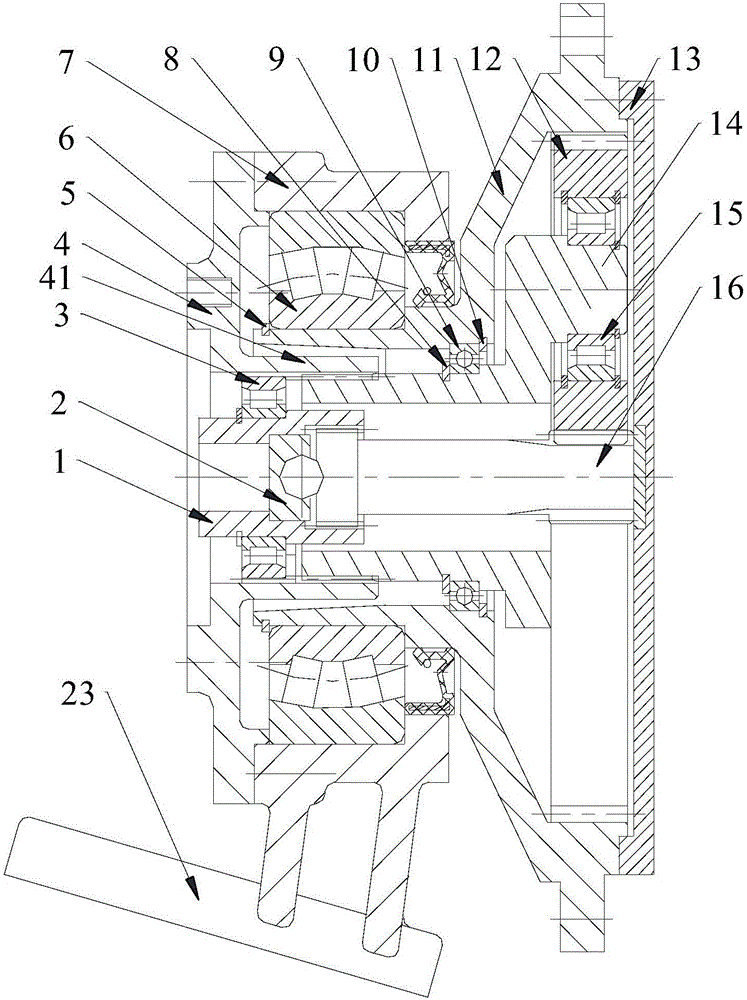

[0071] Please refer to figure 2 According to the first embodiment of the present invention, a speed reducer mainly includes: a box body 7 , an input sleeve 1 , a sun gear 16 , a planetary carrier 14 , a planetary gear 12 , a conjoined ring gear 11 and an end cover 13 .

[0072] Among them, the box body 7 is equipped with a detachable fixed cover 4 at its power input end; the input sleeve 1 is installed in the fixed cover 4 through the first bearing 3; the sun gear 16 is coaxially arranged with the input sleeve 1, and the input sleeve 1 and the sun gear The gears between 16 are connected and transmit power, and a universal swing joint mechanism is arranged between the input sleeve 1 and the sun gear 16.

[0073] The planetary carrier 14 is sleeved on the outside of the sun gear 16 and coaxially arranged with the sun gear 16; the planetary carrier 14 is connected with the fixed cover 4 in rotation, and the planetary carrier 14 is installed with the planetary gear 12 through the...

Embodiment 2

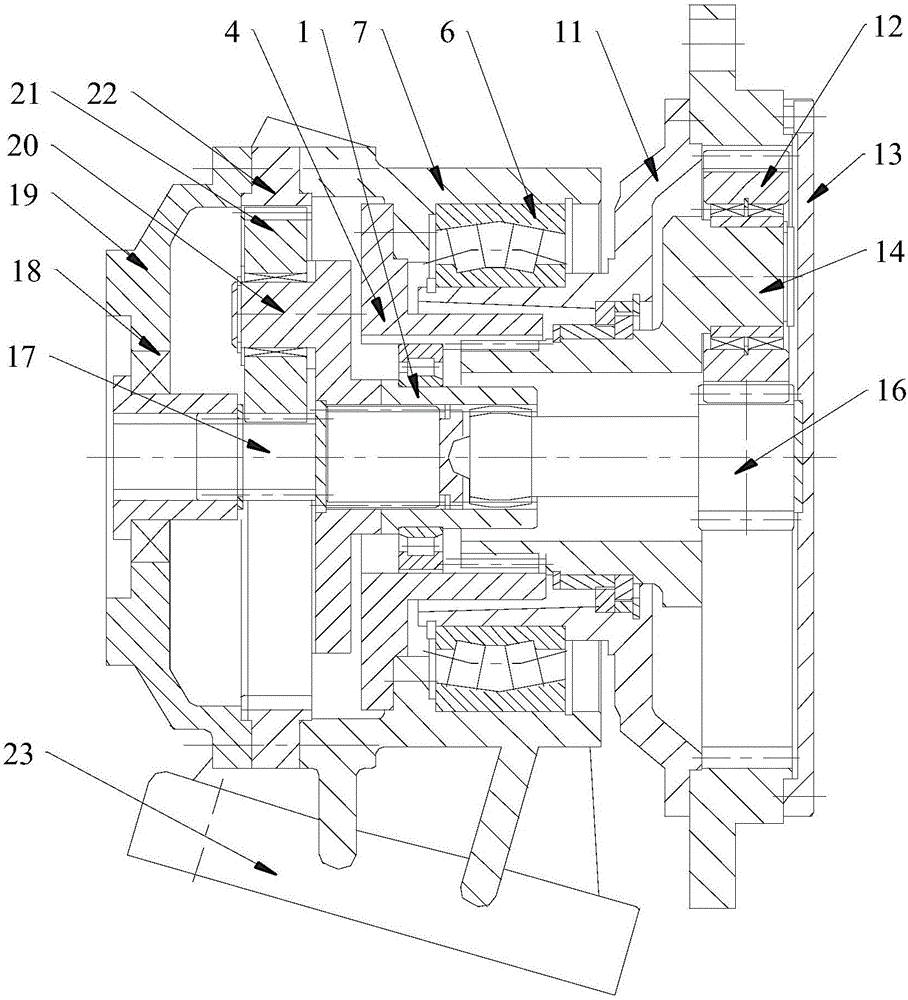

[0093] Such as image 3 As shown, the reducer in the second embodiment mainly includes: a box body 7, an input sleeve 1, a sun gear 16, a planetary carrier 14, a planetary gear 12, a conjoined ring gear 11, an end cover 13, an outer cover 19, a first-stage Sun gear 17, primary planet carrier 20 and primary planetary gear 21. Wherein, in the figure, the sun gear 16 is a secondary sun gear corresponding to the primary sun gear 17, the planet carrier 14 is a secondary planet carrier corresponding to the primary planet carrier 14, and the planetary gear is a secondary planet carrier corresponding to the primary planetary gear 21. Secondary planetary gear.

[0094] Such as image 3 As shown, the outer cover 19 positioned at the outer side of the fixed cover 4 is fixed on the box body 7; the first-level sun gear 17 is installed through the fourth bearing 18 in the outer cover 19, and the input side of the first-level sun gear 17 is connected to the power input end; the first-level...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com