Smokeless warm bath boiler

A technology for boilers and boiler bodies, which is applied in the direction of grates, grates of hollow grates, and combustion methods, etc. It can solve the problems of low boiler thermal efficiency, high exhaust gas temperature, waste of resources, etc. Heat time, the effect of reducing heat energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

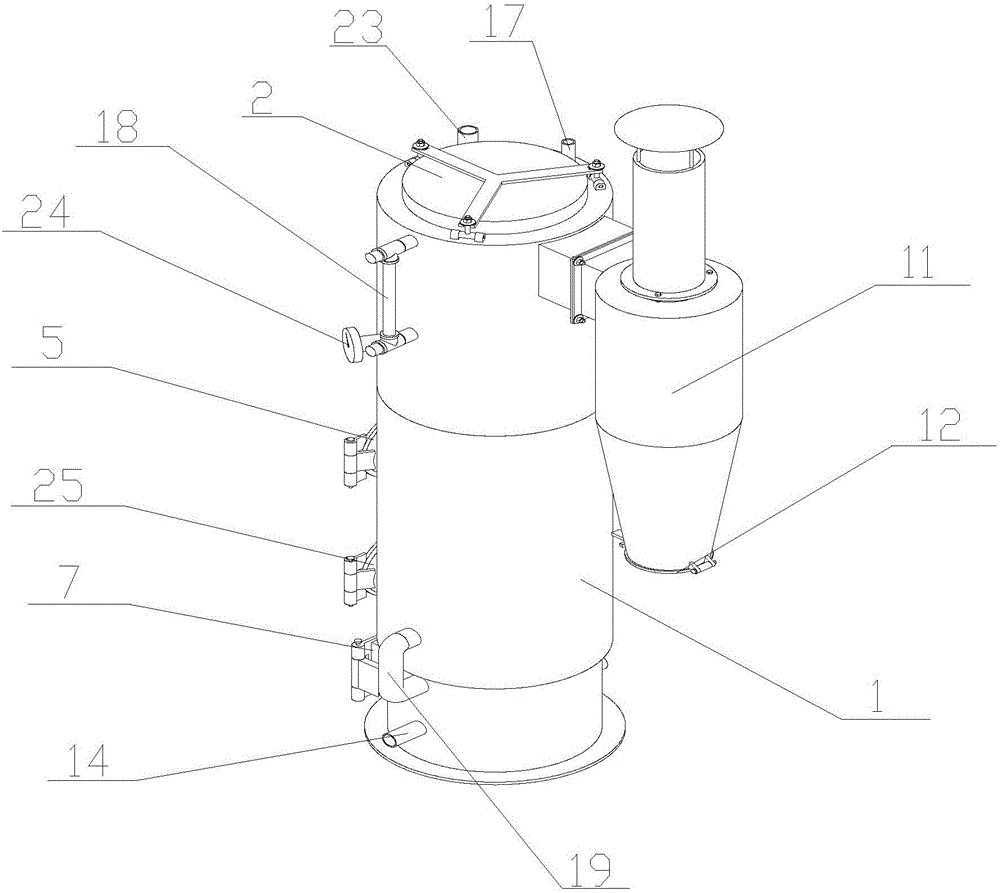

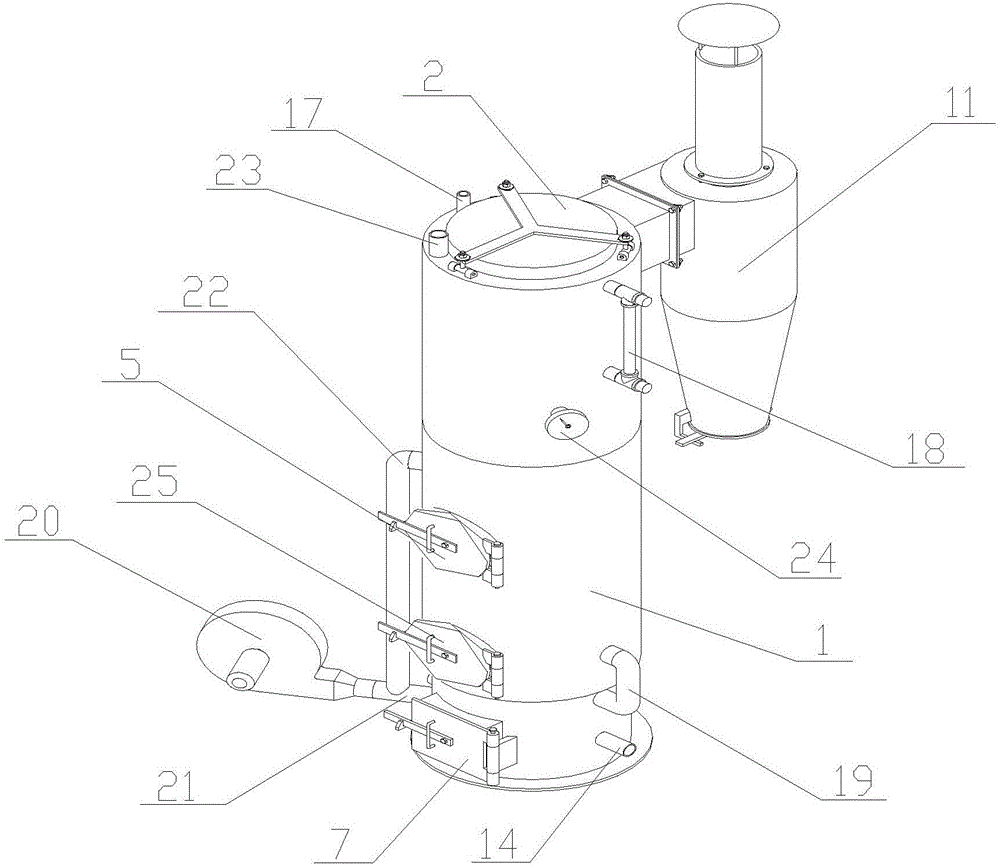

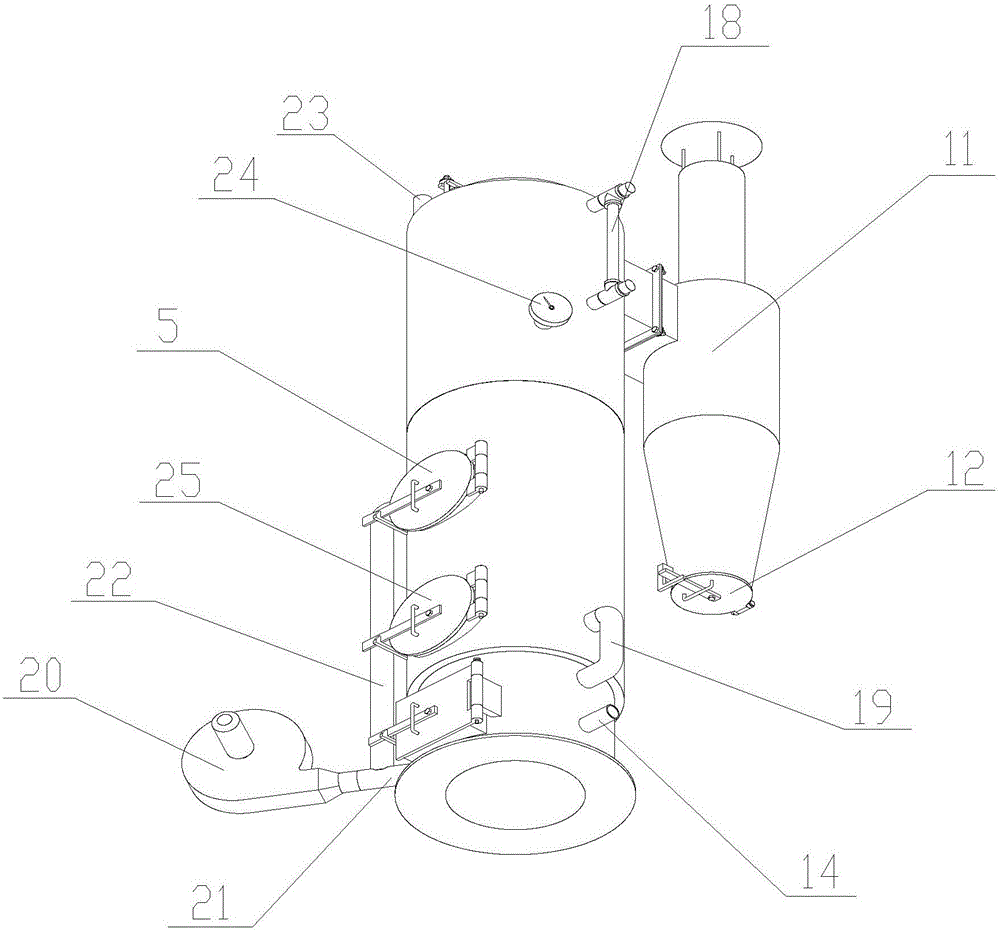

[0038] like Figure 1 to Figure 6 As shown, the smokeless warm bath boiler of this embodiment includes a boiler body 1 , a boiler leg ring, a combustion-supporting fan 20 and a cyclone 11 . The boiler body 1 is installed on the boiler foot ring, the combustion-supporting fan 20 is used to deliver combustion-supporting air to the boiler body 1 , and the cyclone dust collector 11 is used to separate the gas and the dust from the boiler body 1 . Figure 1 to Figure 3 It is a three-dimensional view of the heating bath boiler of this embodiment from three different viewing angles. Figure 4 The front view of this embodiment, Figure 5 The left side view of this embodiment, Image 6 This is a top view of this embodiment.

[0039] The internal structure of the boiler body 1 is as follows Figure 7 to Figure 10 shown. like Figure 10 As shown, the boiler body 1 is a jacket structure, a boiler jacket layer 4 is formed between the outer shell 9 and the inner wall 10 of the boiler ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com