Wind power conductive slip ring electric contact abrasion tester structure

A wear test, conductive slip ring technology, applied in the direction of wear resistance test, etc., can solve the problem of wind power variable pitch slip ring electric contact sliding friction and wear test equipment has no relevant reports, etc., to achieve the effect of good operation and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

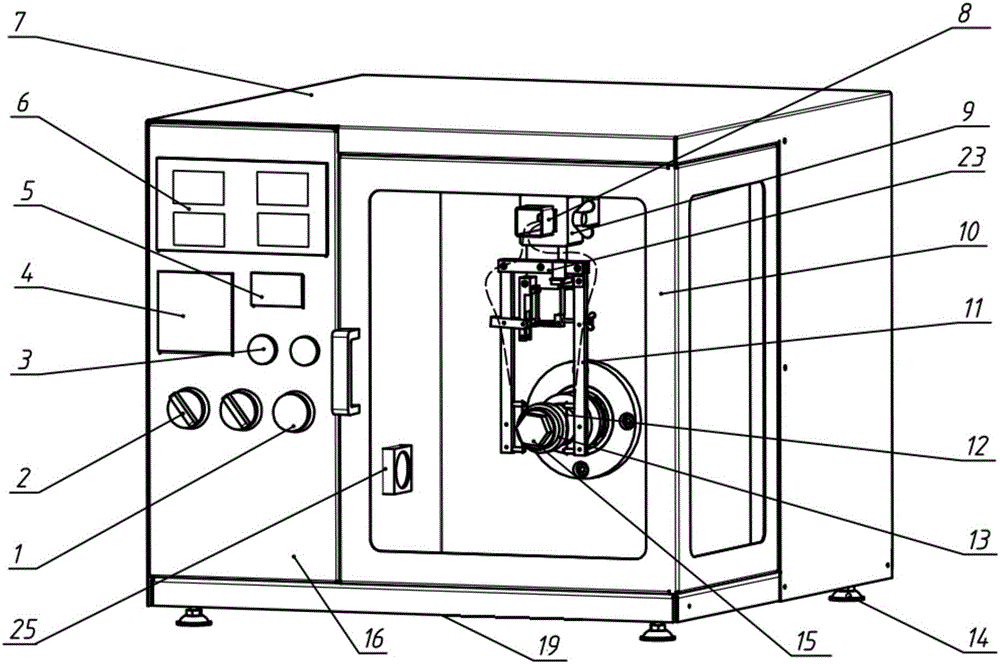

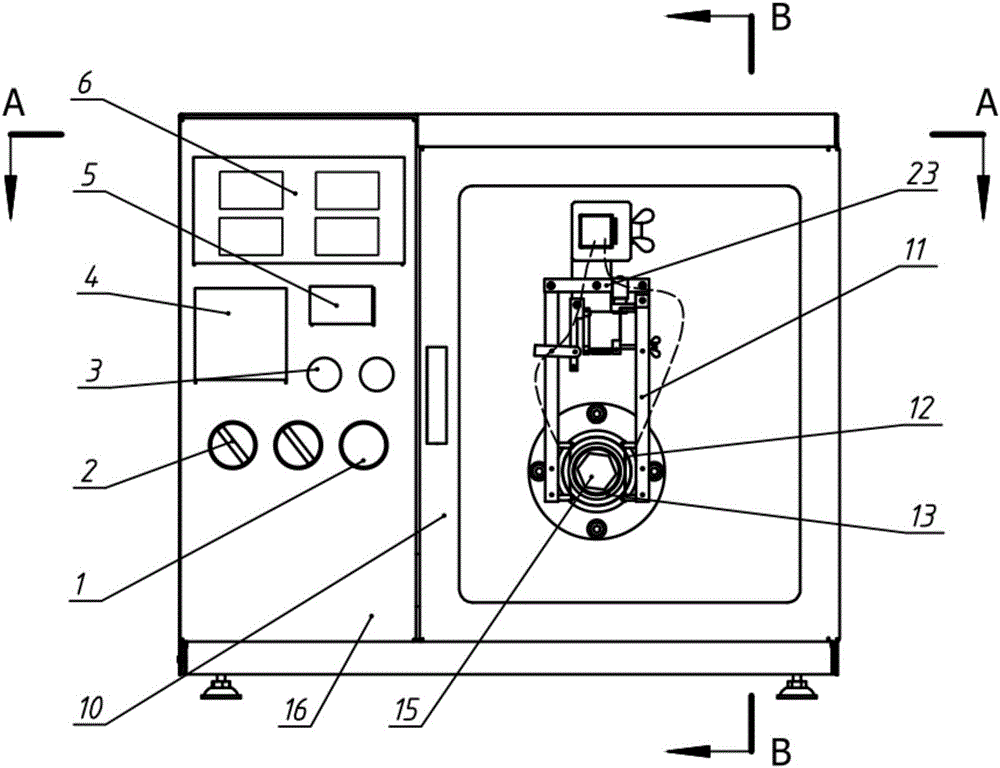

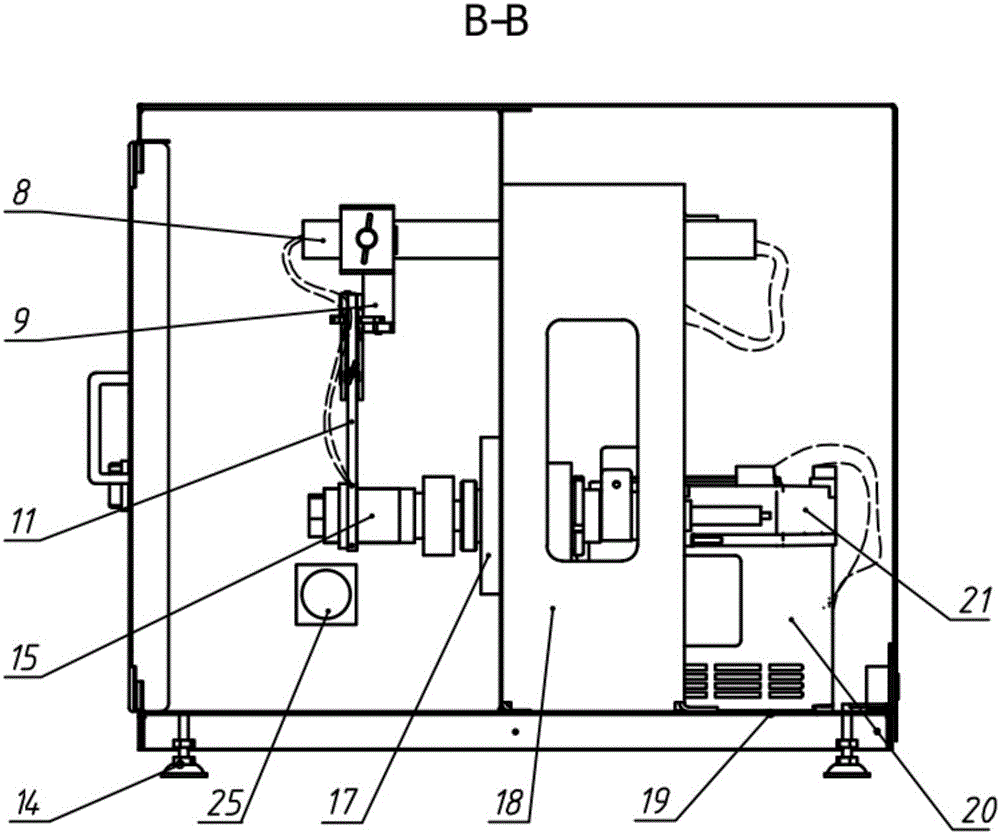

[0017] The specific implementation manner of the present invention will be further described in conjunction with the technical scheme and accompanying drawings.

[0018] Such as figure 1 As shown, a wind power conductive slip ring electrical contact wear tester has a cuboid sheet metal structure in appearance, and is mainly surrounded by a case cover 7, a front panel 16, a hatch 10 and a bottom plate 19 with four legs 14. The wear test chamber 22, spindle drive control, loading contact force and friction force measurement, wear test chamber temperature control and other functional units are set inside, and the contact pressure, wear speed and number of turns of the friction pair can be set, and the charged accelerated friction and wear test can be carried out. It has the functions of data collection, display and transmission.

[0019] Among them, the start switch 2, the speed control knob 1, the indicator light 3, the counter meter 4, the temperature control meter 5 and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com