Waveguide thermo-optic switch and manufacturing method thereof

A manufacturing method and technology of optical switches, applied in optics, nonlinear optics, instruments, etc., can solve the problems of low reliability, large insertion loss, poor stability, etc., and achieve improved performance indicators, low driving power, and reduced production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

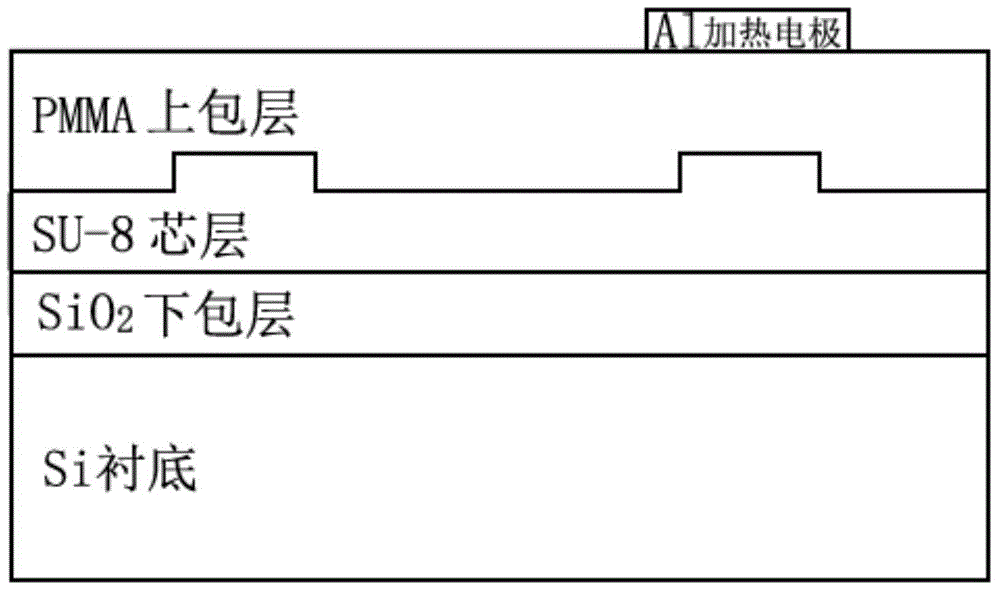

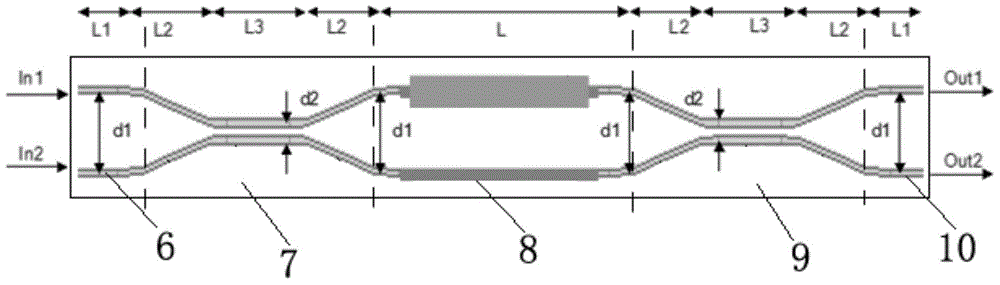

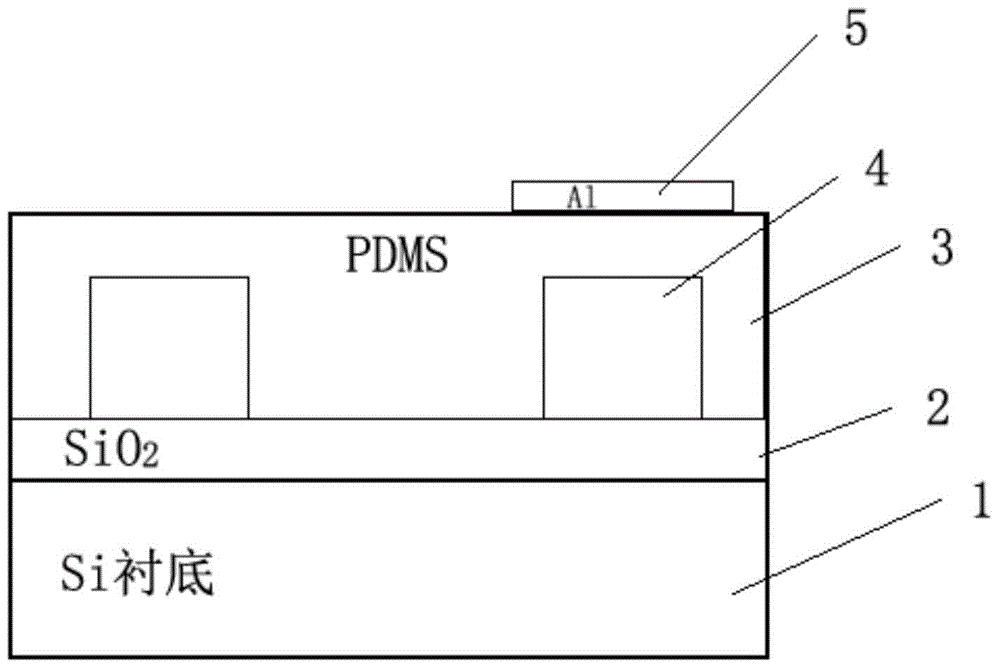

[0046] Such as figure 2 and 3As shown, this embodiment provides a waveguide thermo-optic switch, which sequentially includes a substrate 1, a lower cladding layer 2, an upper cladding layer 3 and a heating electrode 5, and the lower cladding layer 2 is SiO 2 Materials, the upper cladding layer 3 is a polymer material, which is sequentially divided into the input waveguide area 6, the first beam splitting and beam combining area 7, the thermo-optic modulation area 8, the second beam splitting and beam combining area along the length direction of the waveguide thermo-optic switch Region 9 and output waveguide region 10, between the lower cladding layer 2 and the upper cladding layer 3, there are two waveguide cores 4 penetrating in the upper cladding layer 3 along the length direction of the waveguide thermo-optic switch, and the waveguide of the thermo-optic modulation region 8 The material of the core 4 is polymer, and the material of the waveguide core 4 in other regions is...

Embodiment 2

[0057] This embodiment provides a method for manufacturing a waveguide thermo-optical switch, including the following steps:

[0058] In the first step, the lower cladding layer 2 is fabricated on the substrate 1, and the material of the lower cladding layer is SiO 2 . Specifically, firstly, a layer of SiO with a thickness of 3 μm is grown on the substrate 1 of Si material by plasma enhanced chemical vapor deposition (PECVD). 2 material layer, followed by high temperature annealing. The specific process of high temperature annealing is: firstly, the temperature is raised to 120°C at a heating rate of 10-20°C / min and kept for 20-30min; then the temperature is raised to 140°C at a heating rate of 10-20°C / min and kept for 20-30min; Then, raise the temperature to 160°C at a heating rate of 10-20°C / min and keep it warm for 20-30min; finally, cool to room temperature with the furnace. Through the above-mentioned annealing and hardening method, lattice defects and internal stress ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com