Relay ceramic shell for energy-saving car

A ceramic shell and relay technology, applied in the direction of relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve the problems of relay contact bonding failure, continuous arc burning contact system failure, etc., to achieve firm shell body and improve heat resistance and the effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the embodiments and with reference to the accompanying drawings.

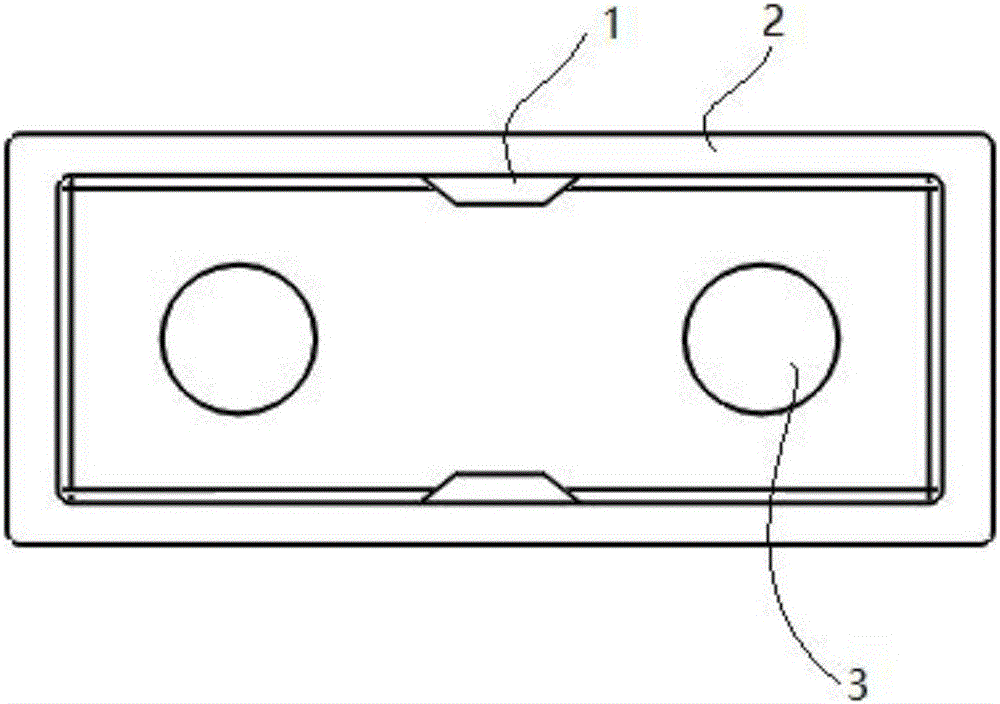

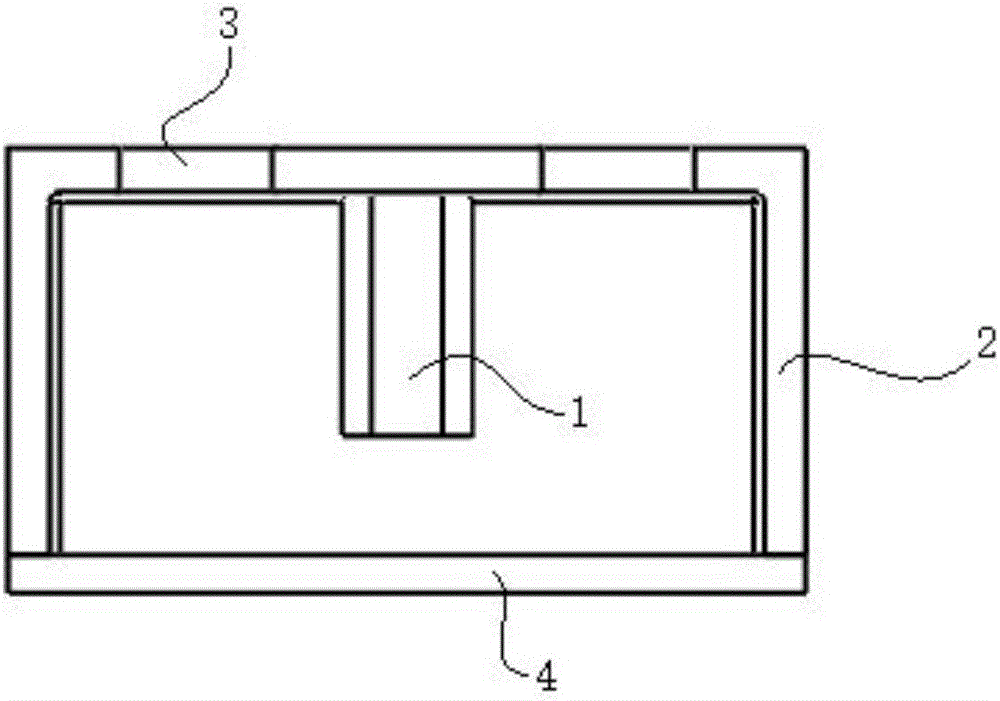

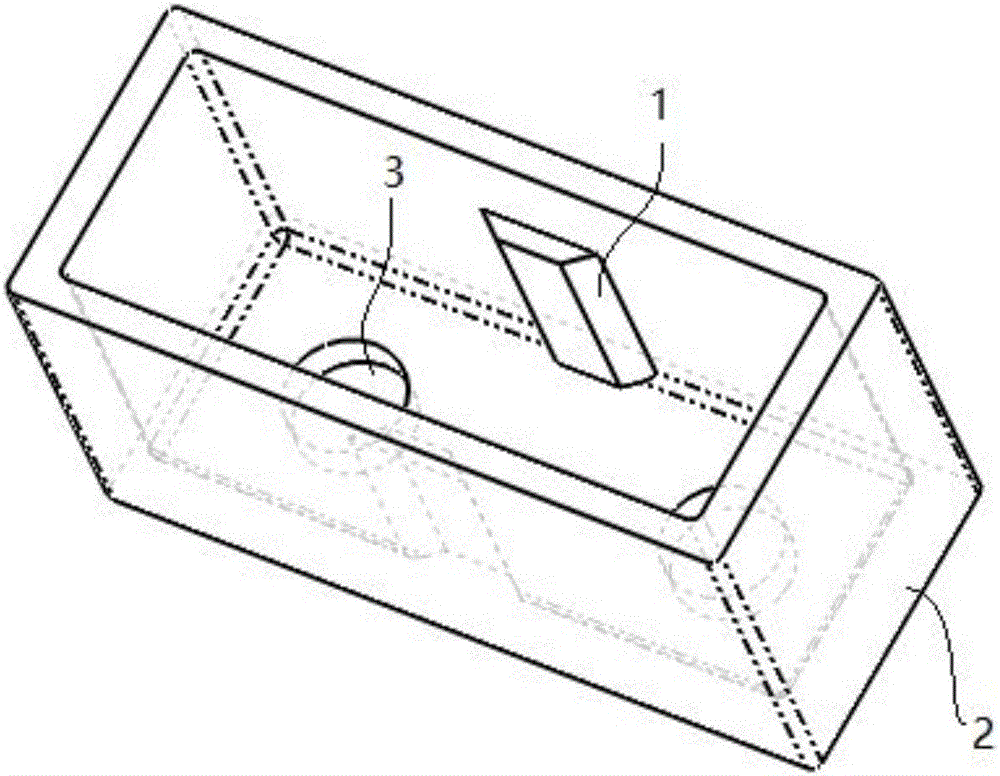

[0024] See Figure 1-Figure 3 .

[0025] An energy-saving automotive relay ceramic case, which is welded by a case body 2 and a cover plate 4, the cover plate 4 is welded to the bottom of the case body 2, the interior of the case body 2 is hollow, and the top surface of the case body 2 is provided with two coil bayonets 3 , respectively located on the left and right sides of the top surface, the inner wall of the shell body 2 is clamped with copper foil cards 1, and the copper foil cards 1 are arranged on the front and rear sides of the inner wall of the shell body 2, and the copper foil cards 1 can be replaced at any time to prevent The entire relay casing cannot be used after being damaged due to high temperature, wear and vibration, and the copper foil card can be used continuously only by replacing the copper foil card; the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com