Porous film, water-resistant and moisture-transmitting material, and medical garment and protective garment using water-resistant and moisture-transmitting material

A porous film, waterproof and moisture-permeable technology, applied in other medical devices, protective clothing, protective equipment, etc., can solve the problems of woven fabric damage barrier, protective clothing barrier, low puncture strength, etc. Excellent comfort, excellent moisture permeability, and the effect of reducing stuffiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

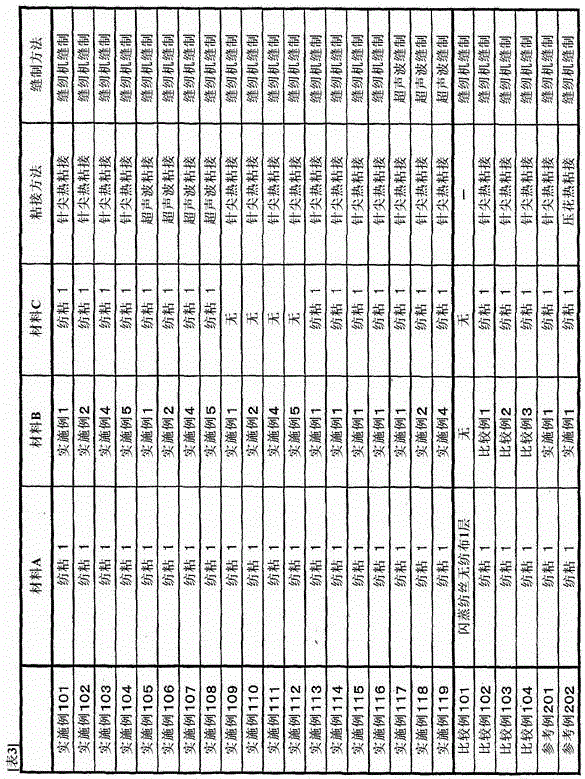

Examples

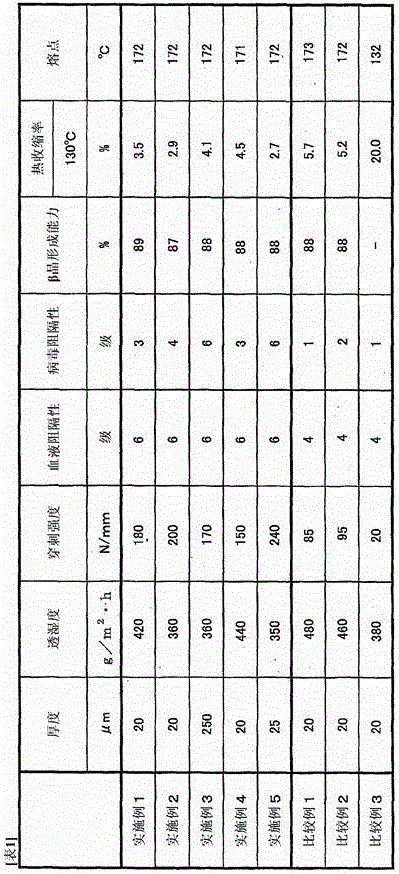

Embodiment 1)

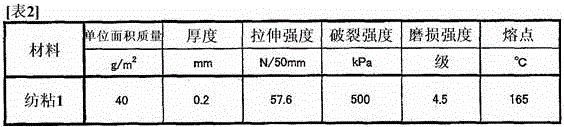

[0158] As a polypropylene resin, 96.5 parts by mass of homopolypropylene manufactured by Prime Polymer Co., Ltd. with MFR = 4.0 g / 10 minutes, and the mass of homopolypropylene S10CL3 manufactured by Prime Polymer Co., Ltd. with an MFR of 1,000 g / 10 min 0.3 parts by mass of N,N'-dicyclohexyl-2,6-naphthalene dicarboxamide (manufactured by Shin Nippon Chemical Co., Ltd., NU-100) as a β-crystal nucleating agent, and BASF Corporation as an antioxidant The produced "IRGANOX" (registered trademark) 1010 and "IRGAFOS" (registered trademark) 168 were mixed in such a ratio that 0.1 parts by mass were supplied from the weighing hopper to the twin-screw extruder, and melt-mixed at 303°C. kneaded, extruded from a die into strands, cooled and solidified in a water bath at 25°C, and cut into small pieces to obtain a polypropylene composition (A).

[0159] The obtained polypropylene composition (A) was supplied to a single-screw melt extruder, and melted and extruded at 220°C. After removing ...

Embodiment 2)

[0163] In the stretching step of Example 1, the film was stretched 5 times in the longitudinal direction at a stretching speed of 400,000% / min (4000 times / min) using ceramic rolls heated to 125°C for preheating. Next, the ends are held and introduced with clips in a tenter-type stretching machine, preheated at 152°C for 3 seconds, and stretched at 150°C at a stretching speed of 4,500% / min (45 times / min). The same conditions as in Example 1 were applied except that the thickness was increased to 9.0 times, and a porous film with a thickness of 20 μm was obtained. Table 1 shows the evaluation results.

Embodiment 3)

[0165] In the extrusion step of Example 1, except that the extrusion amount was adjusted so that the thickness of the porous film became 250 μm, the same conditions as in Example 1 were applied to obtain a porous film with a thickness of 250 μm. Table 1 shows the evaluation results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com