Mechanical transmission type four-wheeled steering and two-wheeled driving wheel-span-variable high-ground-clearance insecticide sprayer

A technology with four-wheel steering and high ground clearance, which is applied to the device for catching or killing insects, applications, animal husbandry, etc. It can solve the problems of affecting spray quality, large turning radius of two-wheel steering, and large pressure loss, etc., and achieves flexibility High performance, reasonable structure design, and small turning radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

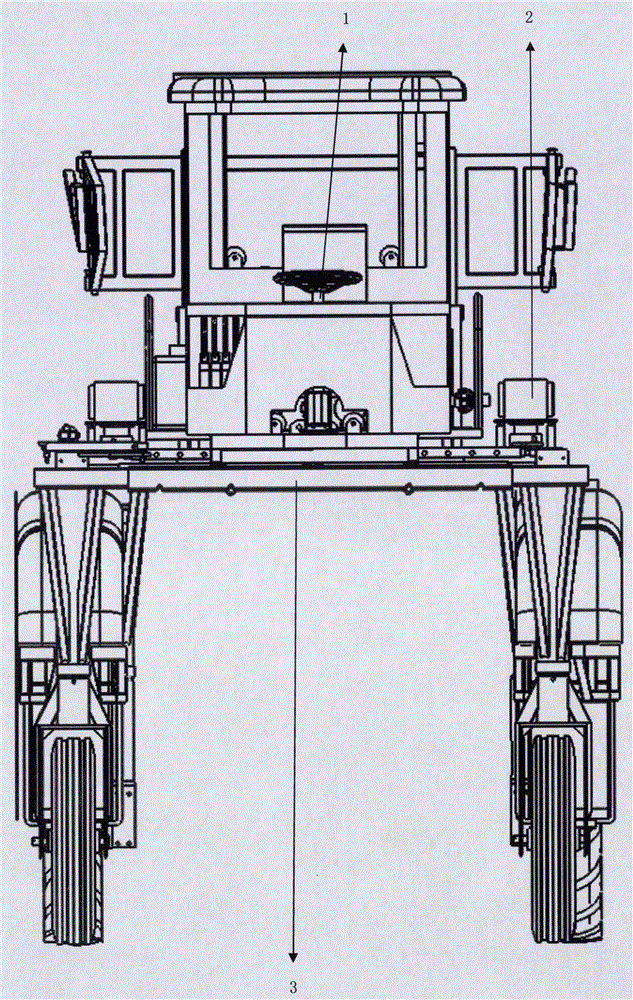

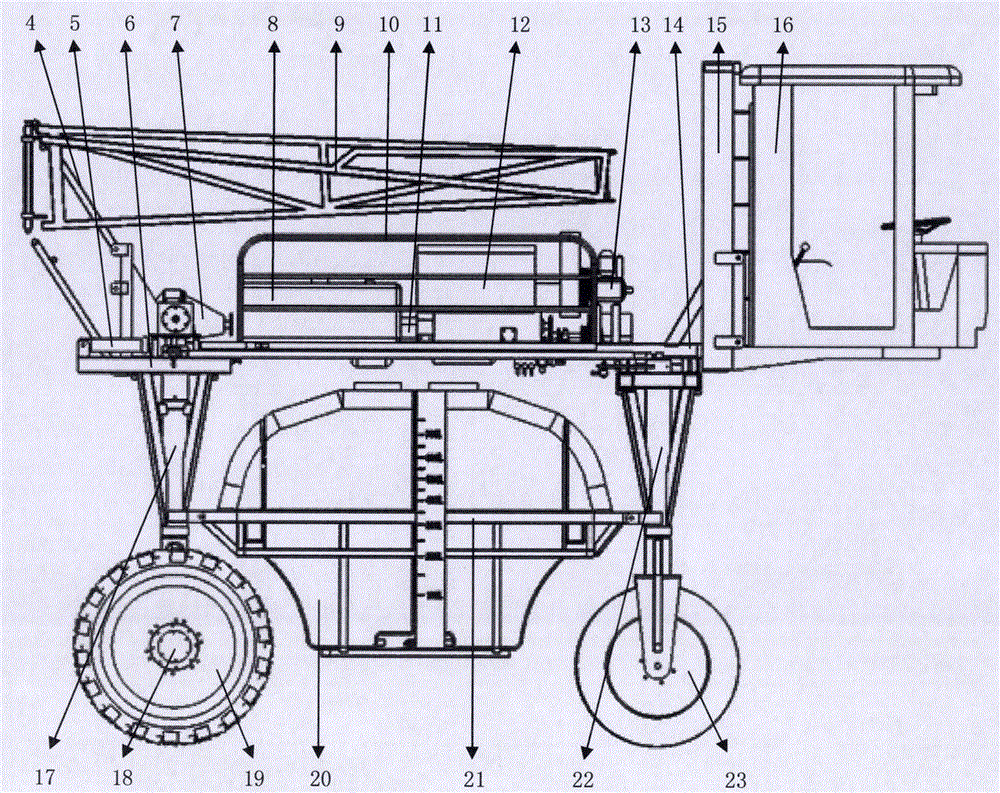

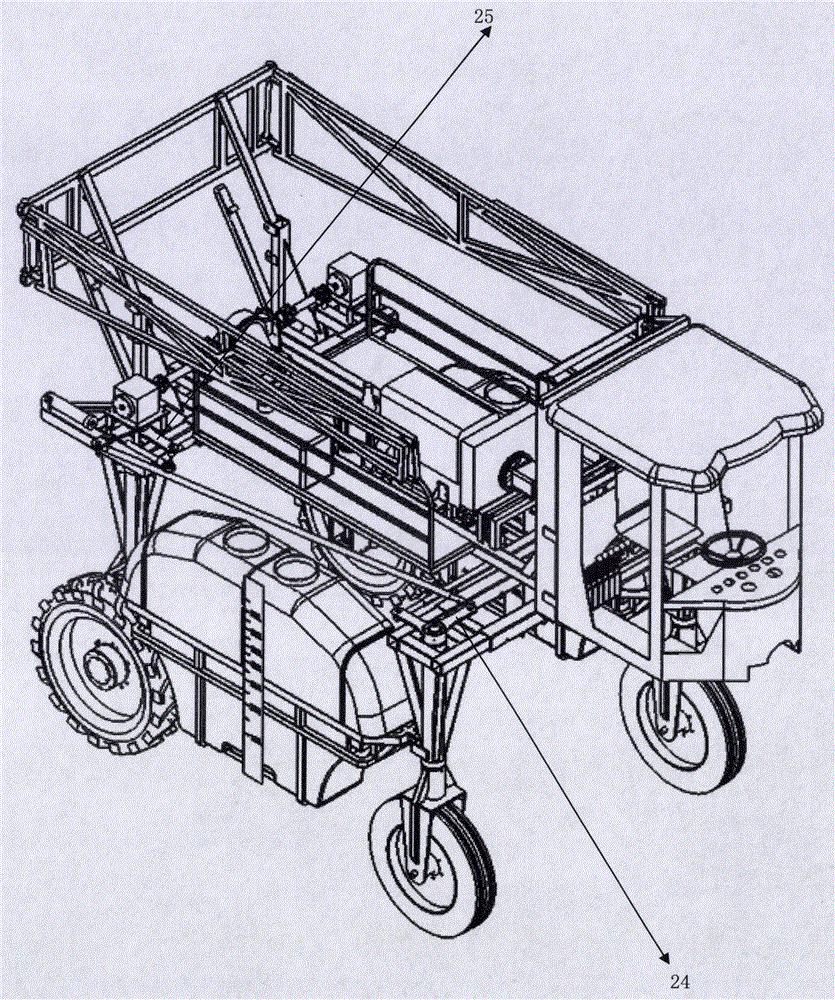

[0012] The preferred embodiment of the present invention is described in detail below in conjunction with accompanying drawing, mechanical transmission type four-wheel steering two-wheel drive variable wheelbase high ground clearance medicine spraying machine, it is made of: steering gear 1, right-angle box 2, front beam 3, spraying machine Drug rack lifting frame 4, steering cylinder 5, rear beam 6, drive axle 7, fuel tank 8, drug spray rack 9, guardrail 10, gearbox 11, engine 12, drug pump 13, beam 14, cab vertical lifting system 15 , cab 16, driving vertical shaft 17, planetary wheel side reducer 18 for high clearance machinery, driving wheels 19, medicine tank 20, medicine tank rack 21, steering vertical shaft 22, guide wheels 23, steering arm 24, steering arm 25 .

[0013] It is characterized in that: the cab 16 is installed at the frontmost position of the sprayer, the hydraulic control system and the steering gear 1 are installed in the cab 16, and the cab 16 is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com