Water cycle automatic dust removal method and device for wood-based panel production

A technology of automatic dust removal and water circulation, applied in the field of dust removal, can solve the problems of non-recycled sewage, exhaust gas that cannot meet the standard, low energy utilization rate, etc., and achieve the effect of low device cost, high degree of automation and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

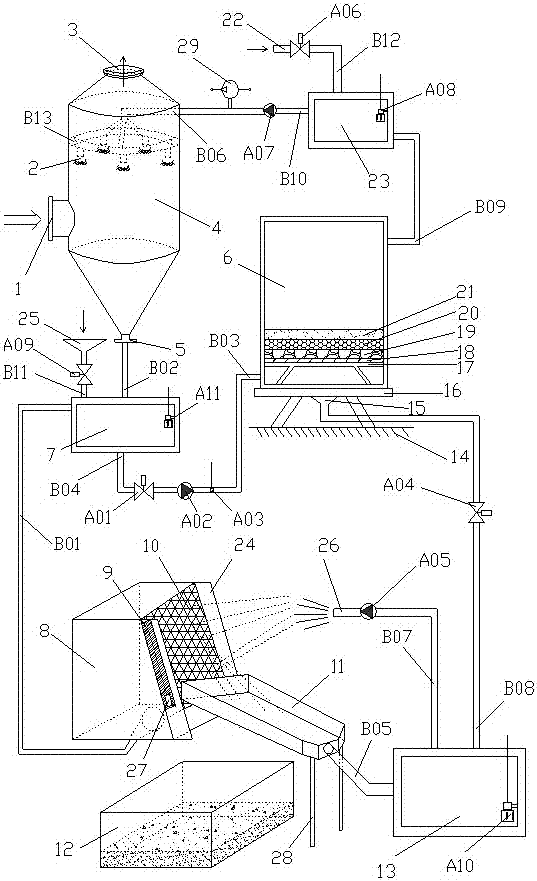

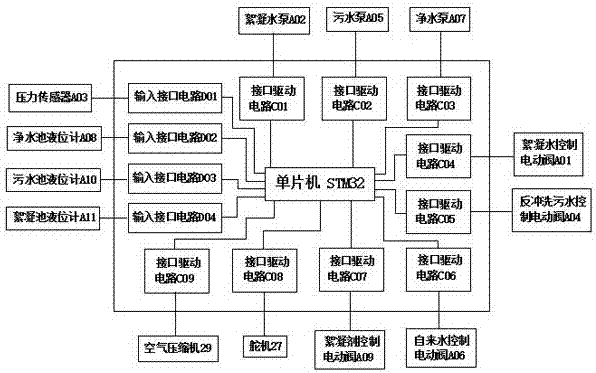

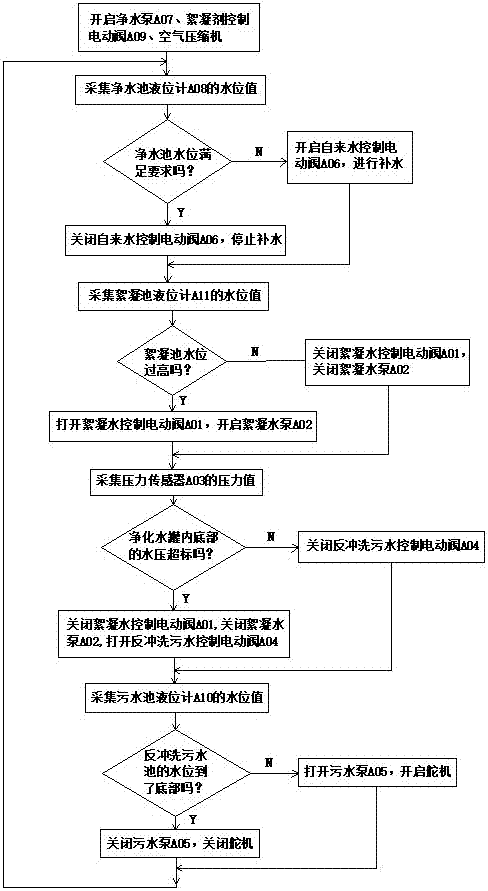

[0026] see figure 1 and figure 2 , The water cycle automatic dedusting device for wood-based panel production of the present invention is mainly composed of a wet dedusting system, a water purification system and a solid-liquid separation system. Among them, the wet dust removal system is composed of water inlet device and spray tower dust collector 4, the water purification system is composed of flocculation buffer tank 7 and purified water tank 6, and the solid-liquid separation system is composed of solid-liquid separator 8, backwash sewage tank 13, etc. composition.

[0027] The water inlet device of the wet dust removal system consists of a clean water buffer tank 23, a clean water tank liquid level gauge A08, a tap water control electric valve A06, a self-boiling water port 22, a clean water pump A07, and an air compressor 29. The water purification buffer pool 23 is a cement pool with an upper end opening. The upper end of the water purification buffer pool 23 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com