3D printing-based microfluidic chip fixture experiment platform

A microfluidic chip and experimental platform technology, applied in the field of microfluidics, can solve the problems of cumbersome and time-consuming connection processes, and achieve the effects of guaranteed connection quality, simple design, low-cost and fast processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

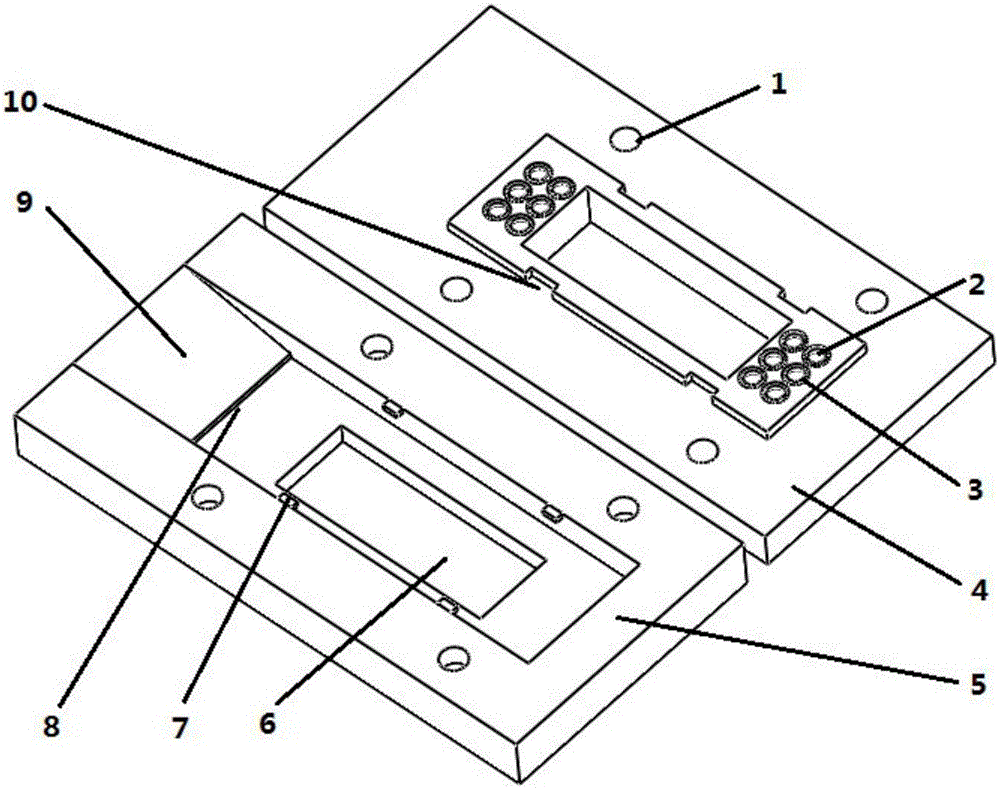

[0015] exist figure 1 Among them, 3D printing is used to manufacture the designed structure, the cover plate (4) is provided with a sealing ring (3), and the sealing ring of the material that is not easily corroded by the fluid used in the experiment is installed at the installation position, and the connecting pipe is installed at the position of the connecting pipe insertion port (2) , the base plate (5) is aligned with the cover plate (4), and the rectangular protrusion (7) is aligned with the rectangular groove (10); after the bolt is connected to the bolt connection hole (1), the base plate (5) and the cover plate (4) ) phase is fixed; during the experiment, enter the microfluidic chip from the slope type microfluidic chip insertion port (9), use the left and right positioning cards (8) to locate, and the rectangular window (6) can observe the flui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com