Clamp for five-star pulling plate milling

A five-star, fixture technology, applied in the direction of clamping, manufacturing tools, supports, etc., can solve the problems of large positioning error, long circulation time, repeated positioning error and bump damage, etc., to reduce product waste loss and improve product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

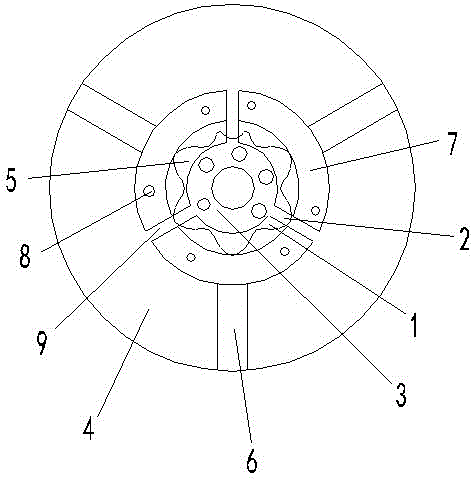

[0018] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

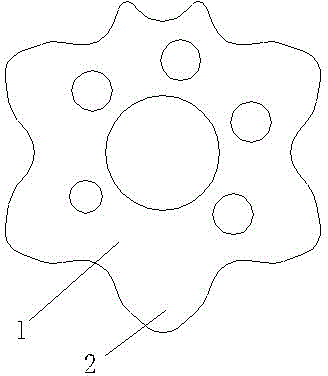

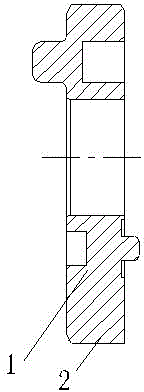

[0019] like image 3 Shown is the schematic structural view of the jig for five-star dial milling of the present invention; a jig for five-star dial milling of the present invention includes a bottom plate 4 arranged on the workbench and no less than three chucks 7 arranged on the bottom plate 4, the The bottom plate 4 is provided with a guide rail 6 for the sliding of the chuck 7, and the chuck 7 is surrounded by a cavity 3 for accommodating the five-star dial 1, and there are no less than two slots between the chucks 7 for accommodating the five-star dial. The groove 9 of the corner 2 of the plate 1 is provided with a locking device on the chuck 7 .

[0020] In this implementation, the five-star dial 1 is fixed in the cavity 3 by moving the chuck 7, and the gap between the chucks 7 is used to fix the corners 2 of the five-star dial 1, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com