Full-automatic multi-procedure synchronous machining composite numerical control machine tool

A composite CNC machine tool and synchronous processing technology, applied in metal processing machinery parts, metal processing, metal processing equipment and other directions, can solve the problems of unguaranteed clamping and positioning, affecting processing accuracy, reducing processing efficiency, etc., to improve work efficiency and The effect of machining accuracy, convenient operation and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings.

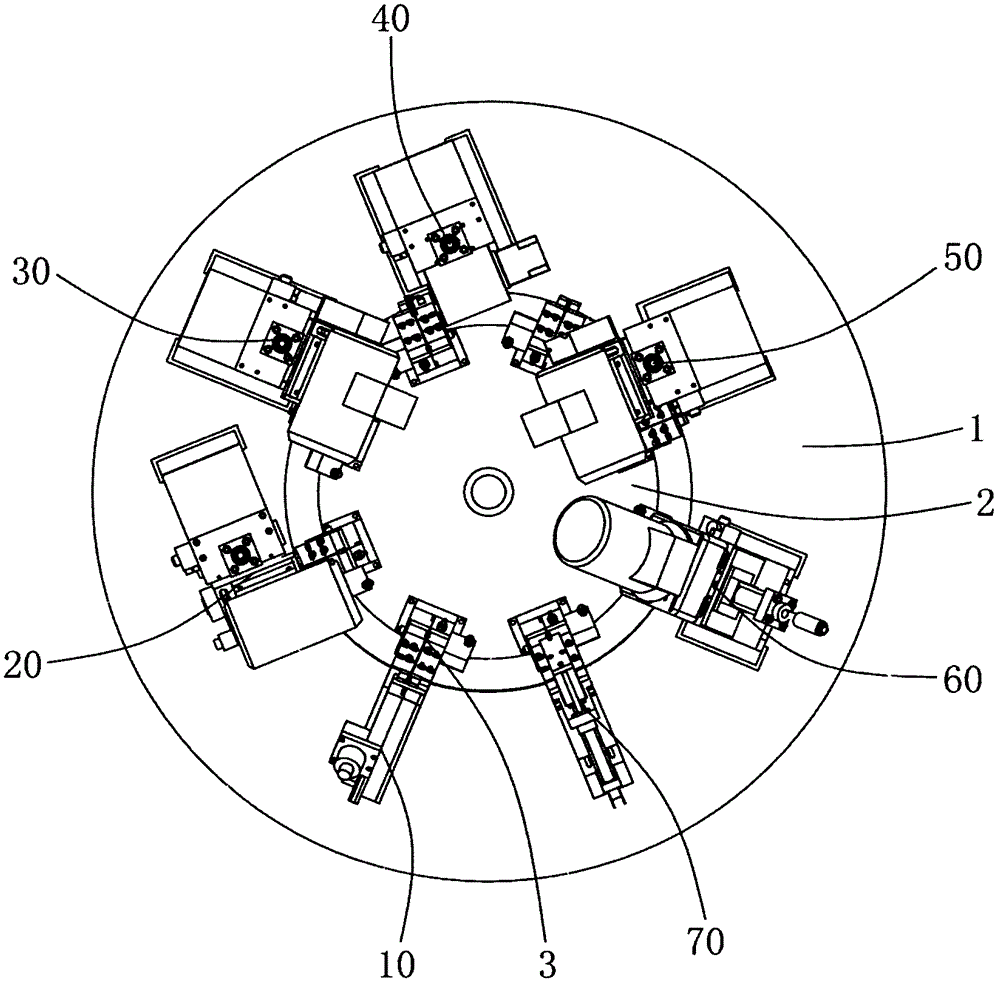

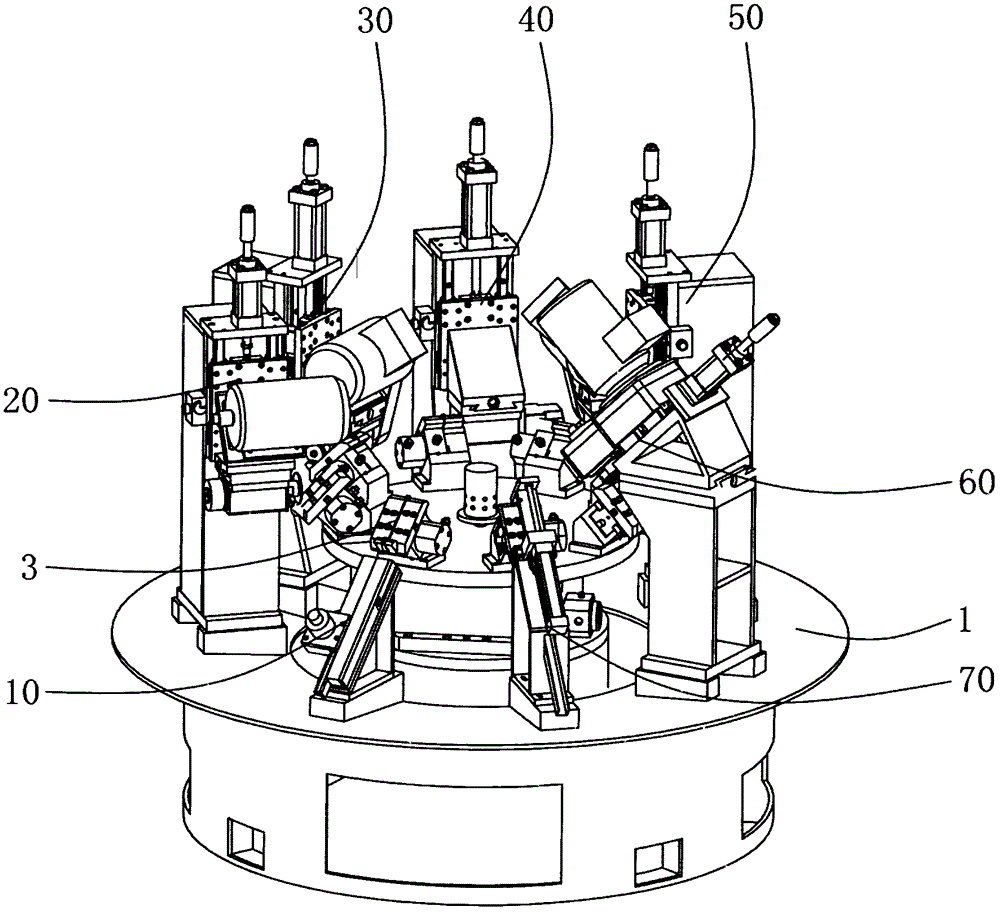

[0039] Such as Figure 1 to Figure 15 A fully automatic multi-process synchronous processing compound numerical control machine tool shown in the figure includes a base 1, an indexing plate 2 rotatably arranged on the base 1, a number of hydraulic clamps 3 are uniformly arranged on the indexing plate 2, and the base 1 is surrounded by The index plate 2 is provided with a loading station, a first station, a second station, a third station, a fourth station, a fifth station and an unloading station in sequence.

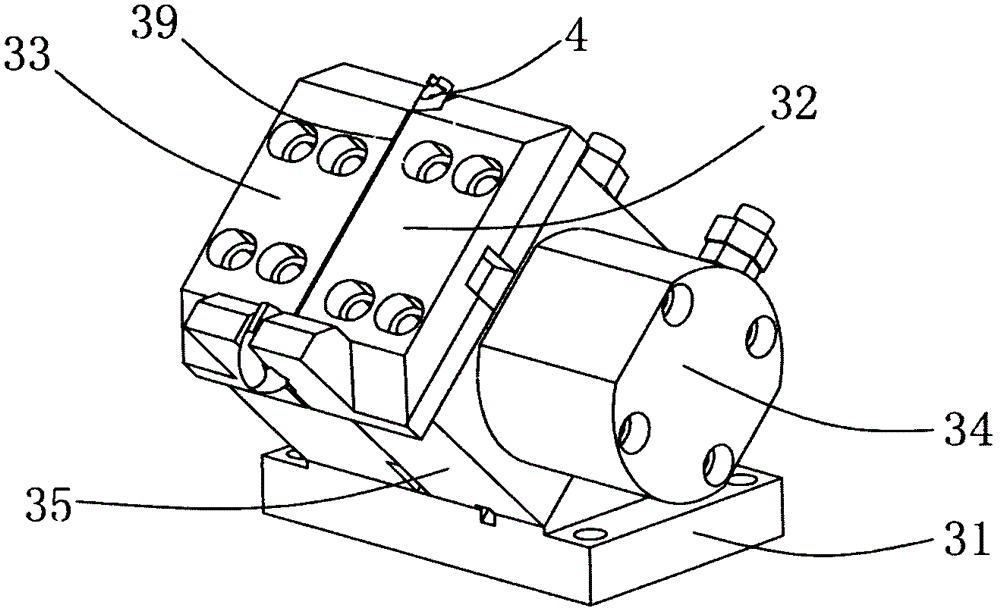

[0040] see image 3 and Figure 4 , the hydraulic clamp 3 includes a clamp base plate 31, a first jaw 32 and a second jaw 33, the clamp base plate 31 is fixedly connected to the base 1, a clamping oil cylinder is arranged on the clamp base plate 31, and the first clamp jaw 32 is fixedly connected to the clamp The oil cylinder body of the oil cylinder, specifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com