Enhanced winding pipe and manufacturing method and device of enhanced winding pipe

A technology for manufacturing equipment and manufacturing methods, which is applied in the direction of mechanical equipment, pipes, rigid pipes, etc., can solve problems such as difficulty in backfilling the abdomen during construction, corrugated holes on the outer wall of pipes, inconvenience in transportation and construction, etc., so that there is no hidden danger of delamination, Avoid cold stress, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing:

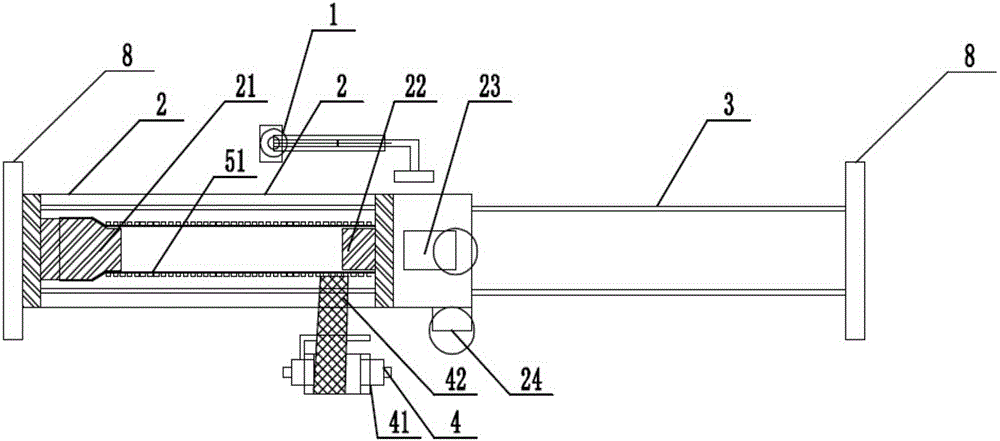

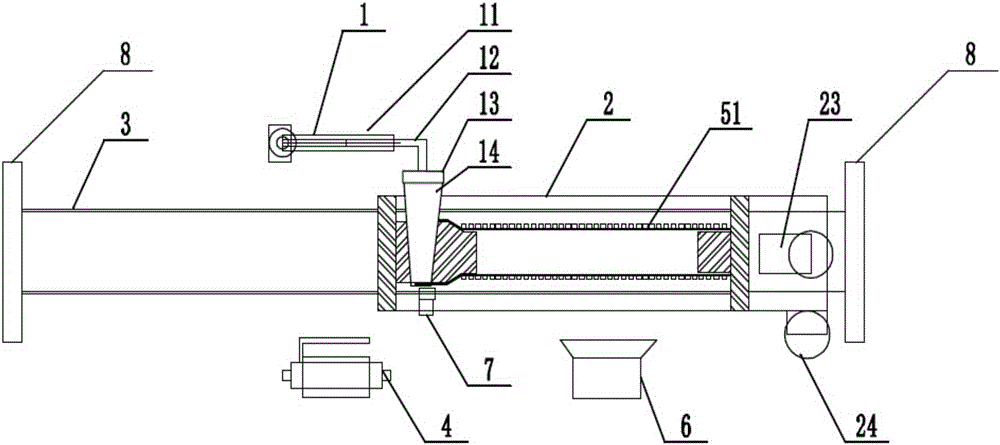

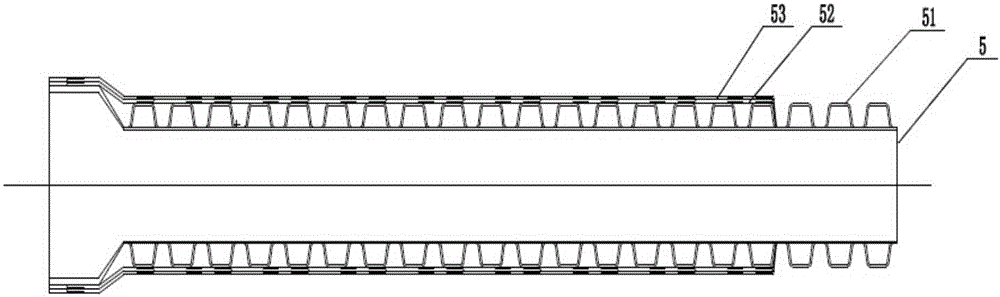

[0032] Such as Figure 1-3As shown, a kind of enhanced winding pipe manufacturing equipment includes a machine base 8, a guide rail 3 and a moving frame 2 are arranged on the machine base 8, the moving frame 2 is installed on the guide rail 3, and the moving frame 2 is provided with a bellows 51 for fixing The first fixed mold 21 at one end and the second fixed mold 22 used to fix the other end of the corrugated tube 51, the enhanced winding tube manufacturing equipment also includes a reciprocating motion for driving the moving frame 2 along the guide rail 3 so as to drive the corrugated tube 51 to move linearly The straight driving device 24 and the rotating drive device 23 for driving the first fixed mold 21 and the second fixed mold 22 to rotate so as to drive the bellows 51 to rotate and directly drive the first fixed mold 21 and the second fixed mold 22 to move relati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com