Electric spare tire lifting frame

An undercarriage and electric technology, which is applied in spare tire arrangement, transportation and packaging, vehicle parts, etc., can solve the problems of easy wear of guide grooves, loss of guiding function, and harsh operating environment, so as to increase service life, not easy to wear, and improve The effect of the work environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

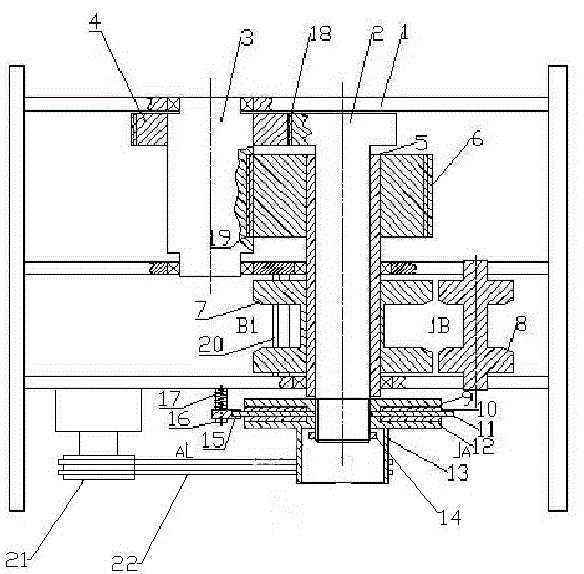

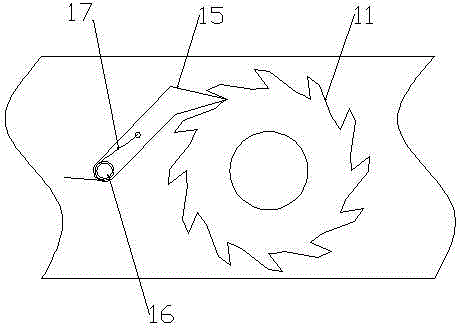

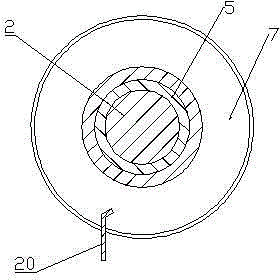

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings. As shown in the figure, the electric spare tire landing gear includes a frame body 1, and a support shaft I2 and a support shaft II3 are arranged side by side on the frame body 1. On the support shaft I2 Shaft sleeve 5 and transmission gear I18 are provided, transmission gear II4 and transmission gear III19 are provided on the support shaft II3, transmission gear IV6 and hanging sprocket 7 are provided on the shaft sleeve 5, transmission gear I18 and transmission The gear II4 meshes with each other, the transmission gear III19 and the transmission gear IV6 mesh with each other, and the support shaft I2 is provided with a stop ratchet 11 on the leading end of the frame body 1, and the frame body 1 is provided with a corresponding stop ratchet 11. Back-stop pawl 15, the transmission gear I and the support shaft I are integral, the transmission gear III and the support sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com