Automatic transmission cabinet

An automatic transmission and automatic technology, applied in the direction of conveyor objects, transportation and packaging, power control mechanism, etc., can solve problems such as difficult to ensure pressure difference requirements, room pollution, energy loss, etc., to reduce the risk of cross-contamination and reduce labor Strength, anti-pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

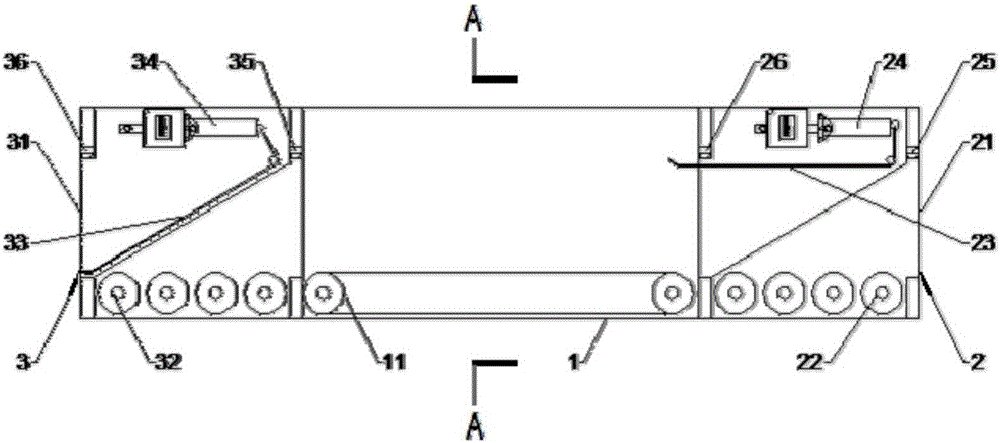

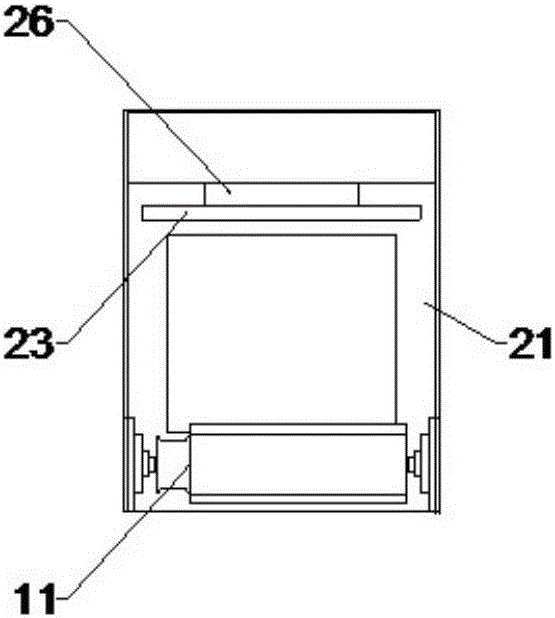

[0024] Such as Figure 1-2 As shown, the automatic transmission transfer cabinet of the present invention includes a cabinet body 1 with a front cabinet door 2 and a rear cabinet door 3 at the front and rear ends respectively, and the cabinet body 1 is composed of upper, lower, left and right four sides. Two pieces of wall panels are sealed and connected to form a cabinet body with openings at both ends. An automatic transmission belt 11 is arranged in the cabinet body 1, and the front cabinet door 2 includes a front door frame 21, an automatic transmission line 122, and a front automatic door panel 23. The front automatic door panel The upper end of 23 is hinged with the front door frame 21, and the automatic transmission line I22 is arranged above the lower wall plate of the front door frame 21, and the front electric push mechanism 24 is fixedly installed on the upper wall plate of the front cabinet door 2, and the front electric push mechanism 24 is connected with the front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com