Mobile Side Feed Chain Bulk Stacker

A mobile stacking machine technology, applied in the field of construction machinery, can solve the problems of poor mobility of equipment, low utilization rate of the stockyard, high useless energy consumption, etc., and achieve safe and reliable one machine with multiple functions, adjustable stacking height, and low useless The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

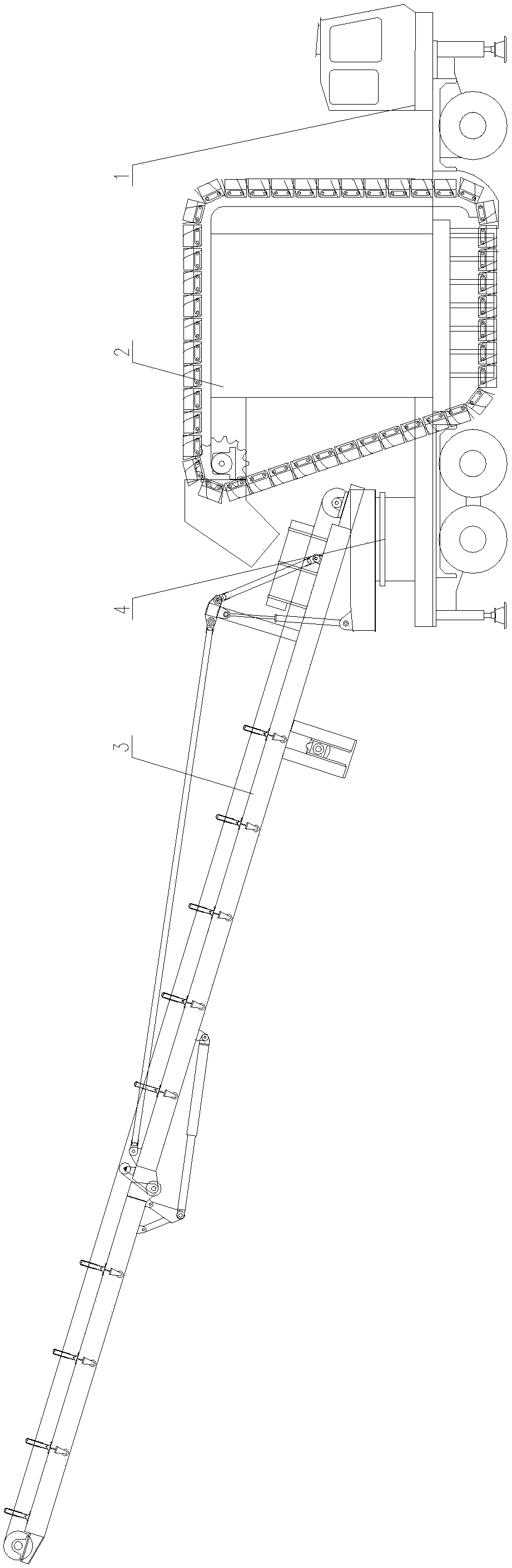

[0040] Such as figure 1As shown, the flow type side feeding chain type bulk material stacker 42 includes a car body assembly 1 , a material transfer device 2 , a folding belt conveyor 3 , and a rotary mechanism 4 . The car body assembly 1 is used as the carrier of the whole machine equipment, and is used for installing the transfer material device 2, the folding belt conveyor 3 and the turning mechanism 4 and the walking and transition of the whole machine. The transfer material device 2 is located in the middle of the car body assembly 1 and is fixedly connected with the vehicle frame 7. Its horizontal section is combined with the bottom side plate of the conveying device support frame 22 to form a material receiving trough 23, which is used to accept the unloading of the dump truck 43, and The material is lifted and transported to the receiving hopper 15 of the folding belt conveyor 3 by means of the endless conveying device. The rotary platform 17 of the rotary mechanism 4...

Embodiment 2

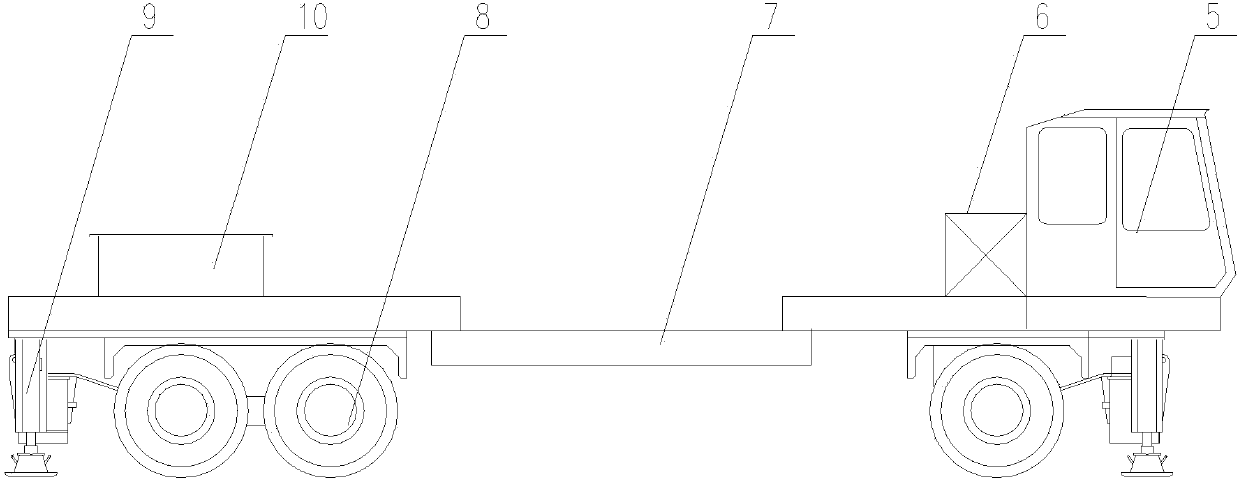

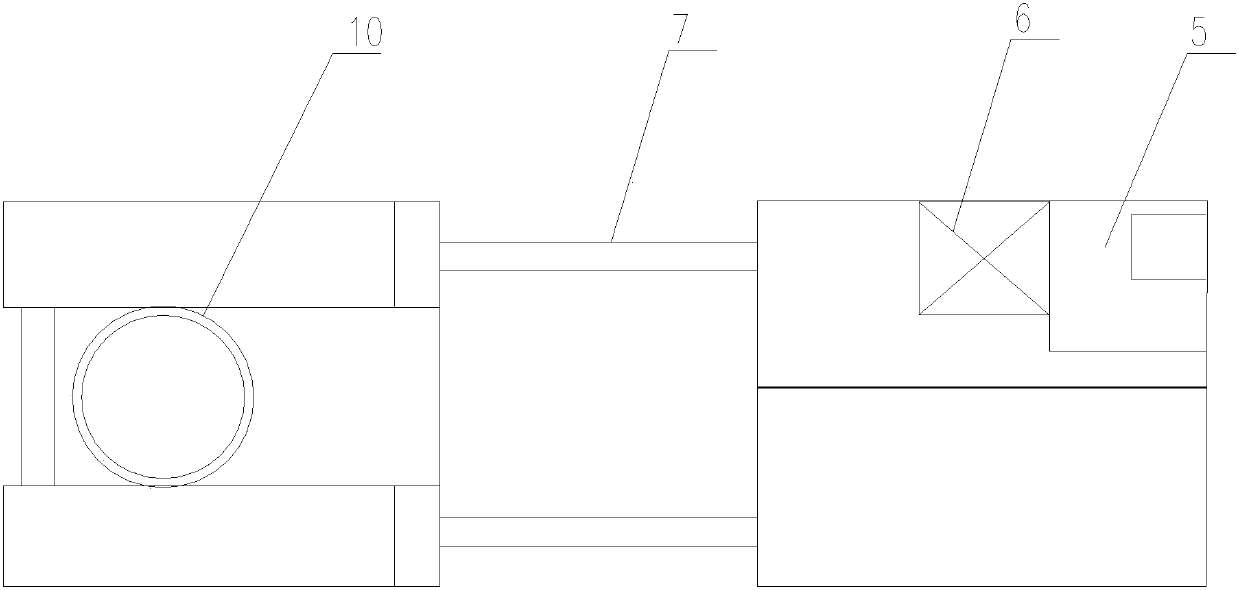

[0049] Such as Figure 12 As shown, the flow type side feeding chain type bulk material stacker 42 includes a car body assembly 1, a transfer material device 2, a folding belt conveyor 3, and a rotary mechanism 4. The car body assembly 1 is used as the carrier of the whole machine equipment, and is used for installing the transfer material device 2, the folding belt conveyor 3 and the turning mechanism 4 and the walking and transition of the whole machine. The transfer material device 2 is located in the middle of the vehicle body assembly 1 and is fixedly connected to the vehicle frame 7. Its material conveying horizontal section is combined with the bottom side plate of the conveying device support frame 22 to form a material receiving trough 23, which is used to receive the unloading of the dump truck 43. , and the material is lifted and transported to the receiving hopper 15 of the folding belt conveyor 3 through the endless conveying device. The rotary platform 17 of the...

Embodiment 3

[0056] Such as Figure 15 As shown, the flow type side feeding chain type bulk material stacker 42 includes a car body assembly 1, a transfer material device 2, a folding belt conveyor 3, and a rotary mechanism 4. The car body assembly 1 is used as the carrier of the whole machine equipment, and is used for installing the transfer material device 2, the folding belt conveyor 3 and the turning mechanism 4 and the walking and transition of the whole machine. The transfer material device 2 is located in the middle of the vehicle body assembly 1 and is fixedly connected to the vehicle frame 7. Its material conveying horizontal section is combined with the bottom side plate of the conveying device support frame 22 to form a material receiving trough 23, which is used to receive the unloading of the dump truck 43. , and the material is lifted and transported to the receiving hopper 15 of the folding belt conveyor 3 through the annular scraper conveying device. The rotary platform 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com