Shale gas well drilling waste-oil-based mud curing material

A technology of oil-based mud and curing materials, which is applied in the field of curing materials and shale gas well drilling waste oil-based mud curing materials. Good for sustainability, high strength and stability, low leaching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

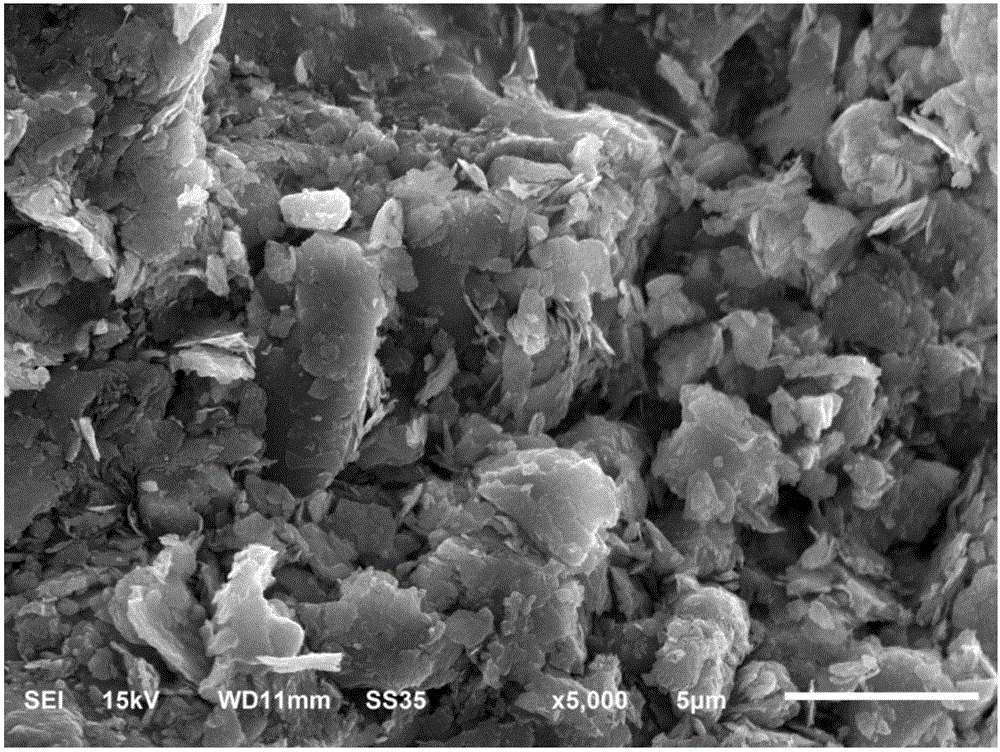

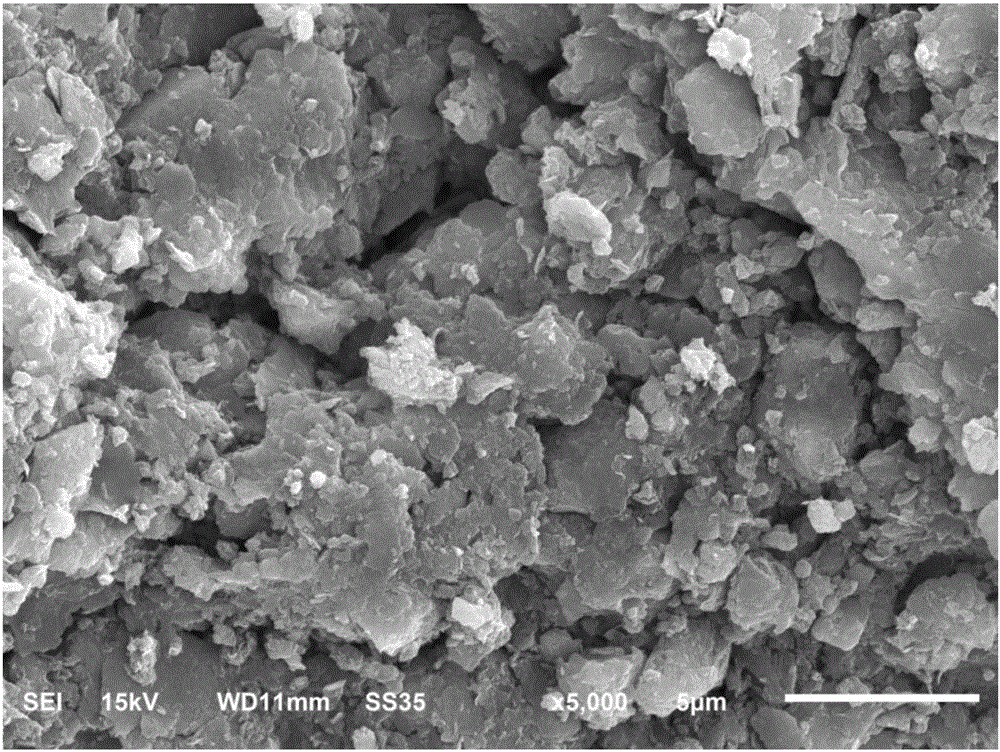

Image

Examples

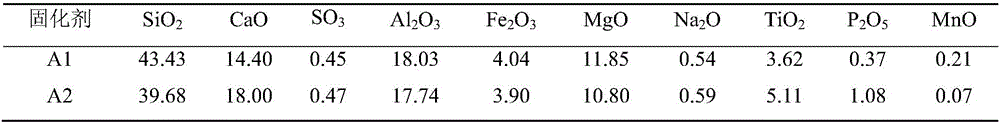

Embodiment 1

[0026] In this embodiment, the mixing ratio of the solidified material of waste oil-based mud from shale gas well drilling is: 20% of oil-based mud, 70% of sand, 4% of curing agent (A1), and 6% of water. Put the oil-based mud, sand, and curing agent in a mixing pot and mix evenly, then add the mixing water and mix for 5 minutes. After discharging, press the mixed solidified material into a shape with a testing machine, prepare a sample of 4cm*4cm*16cm size, and standard curing.

Embodiment 2

[0028] In this embodiment, the mixing ratio of the solidified material of waste oil-based mud from shale gas well drilling is: 30% of oil-based mud, 60% of sand, 4% of curing agent (A2), and 6% of water. Put the oil-based mud, sand, and curing agent in a mixing pot and mix evenly, then add the mixing water and mix for 5 minutes. After discharging, press the mixed solidified material into a shape with a testing machine, prepare a sample of 4cm*4cm*16cm size, and standard curing.

Embodiment 3

[0030] In this embodiment, the mixing ratio of the solidified material of waste oil-based mud from shale gas well drilling is: 22% of oil-based mud, 60% of sand, 8% of curing agent (A1), and 10% of water. Put the oil-based mud, sand, and curing agent in a mixing pot and mix evenly, then add the mixing water and mix for 5 minutes. After discharging, press the mixed solidified material into a shape with a testing machine, prepare a sample of 4cm*4cm*16cm size, and standard curing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com