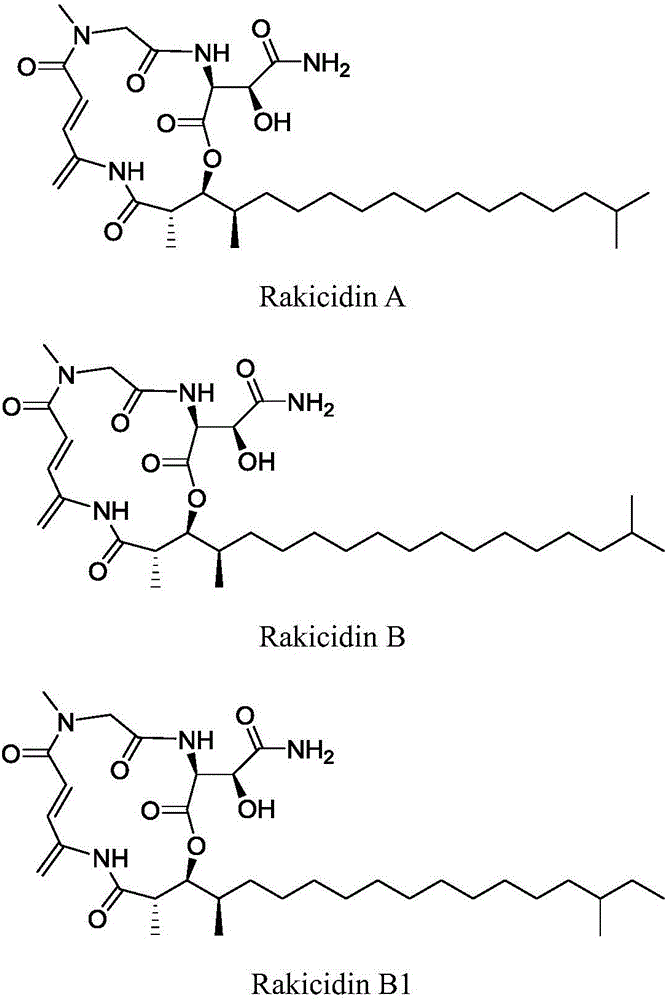

Method for producing Rakicidins compounds by virtue of marine micromonospora fermentation

A compound and fermenter technology, applied in the field of industrial microorganisms and biopharmaceuticals, can solve the problems of low fermentation titer and inability to achieve industrialized production, and achieve the effect of meeting the needs of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

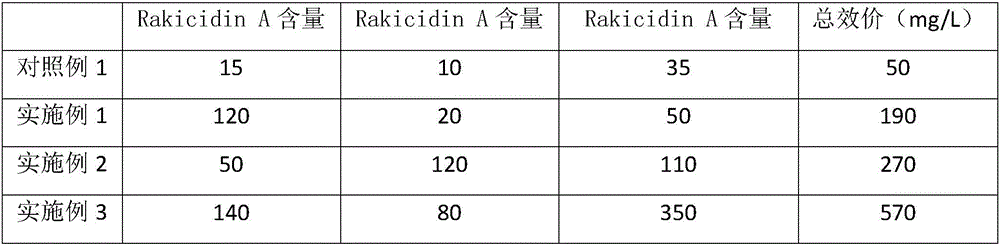

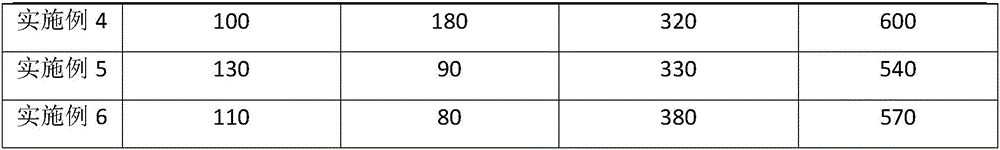

Embodiment 1

[0036] Micromonospora marine (Micromonospora sp. FIM02-523) spores preserved on a solid slope were scraped and inoculated into a shake flask primary seed culture by scraping the spores, and cultured at 28° C. and 220 rpm for 48 hours.

[0037] Seed medium formula (%): soluble starch 2.0, glucose 1.0, yeast powder 2.0, peptone 1.0, MgSO 4 ·7H 2 O0.05, FeSO 4 ·7H 2 O0.005, CuSO 4 ·5H 2 O0.005, CoCl 2 ·6H 2 O0.0005, CaCO 3 0.1~0.3, prepared with tap water, pH, 7.0~7.5; 28~32℃.

[0038] Then inoculate 5% inoculum in a 20L fermenter (actual liquid volume 15L) for fermentation, culture at 28°C, start at 200rpm, adjust to 350rpm after 48 hours, and finish fermentation for about 96-120 hours. The tank pressure is 0.03-0.05Mpa, and the ventilation volume is 1:1vvm.

[0039] The fermentation medium is: soluble starch 5.0, sucrose 1.0, soybean cake powder 3.0, yeast powder 1.0, MgSO 4 ·7H 2 O0.04, FeSO 4 ·7H 2 O0.005, CuSO 4 ·5H 2 O0.005, CoCl 2 ·6H 2 O0.0005, CaCO 3 0....

Embodiment 2

[0041] The basic conditions of the fermentation process are the same as in Example 1, except that 0.2% methionine in the volume content of the fermentation broth is added at one time after 24 hours of fermentation. During the fermentation process, the content of Rakicidins compounds in the fermentation broth was detected by HPLC. The final fermentation titer was 270mg / L, wherein the content of RakicidinA was 50mg / L, the content of RakicidinB1 was 120mg / L, and the content of RakicidinB was 110mg / L.

Embodiment 3

[0043] The basic conditions of the fermentation process are the same as in Example 1, except that 0.3% glycine in the volume content of the fermentation broth is added at one time after 24 hours of fermentation. During the fermentation process, the content of Rakicidins compounds in the fermentation broth was detected by HPLC, and the final fermentation titer was 570mg / L, wherein the content of RakicidinA was 140mg / L, the content of RakicidinB1 was 80mg / L, and the content of RakicidinB was 350mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com