An energy-saving thermal cycle filling machine

A seam filling machine and thermal cycle technology, applied in the direction of roads, road repair, roads, etc., can solve the problem that the heat energy of the seam filling machine cannot be fully covered and circulated, the asphalt or the seam filling glue is heated unevenly, and the work efficiency of the seam filling machine is affected, etc. problem, to achieve the effect of good melting effect, short standby time and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings.

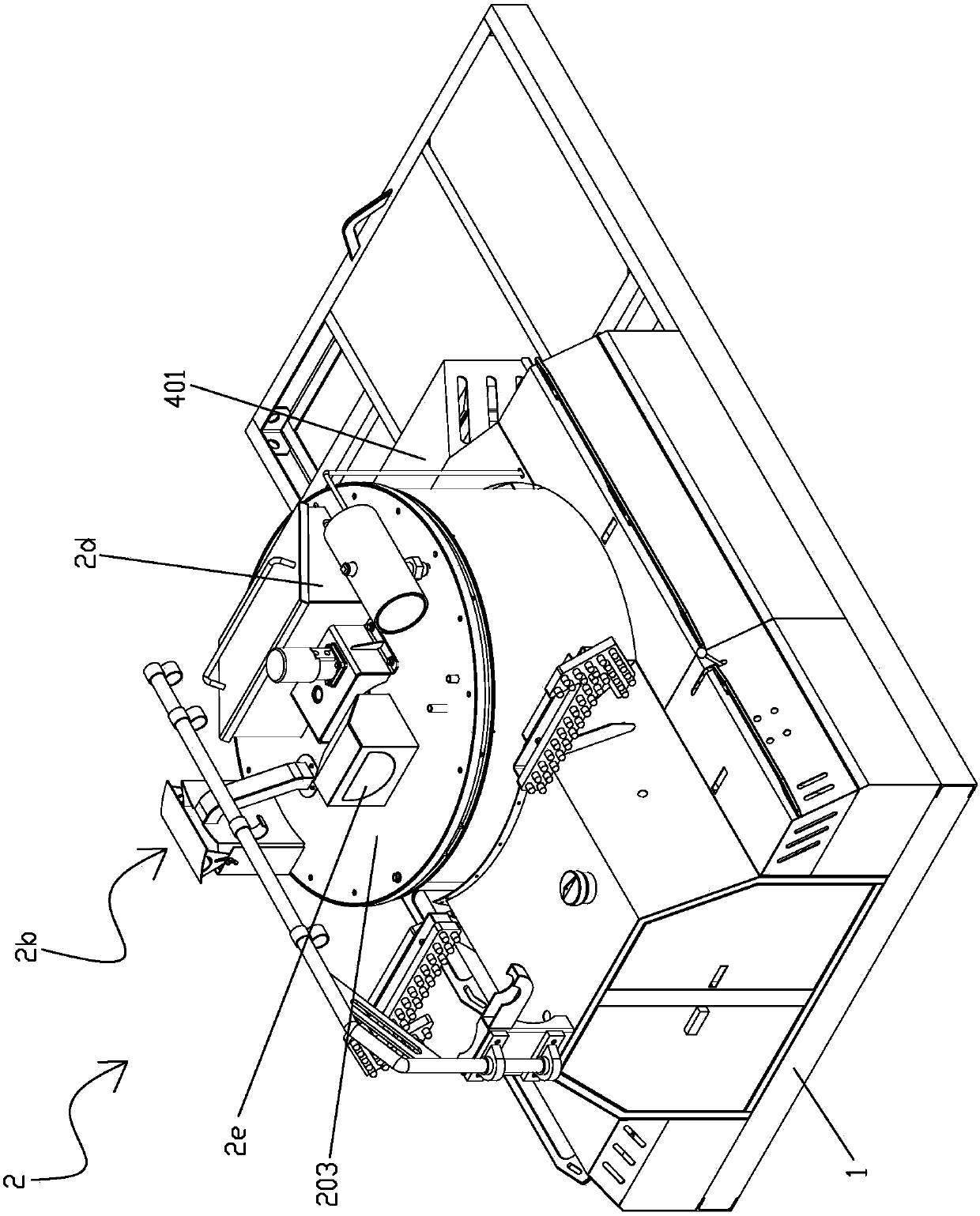

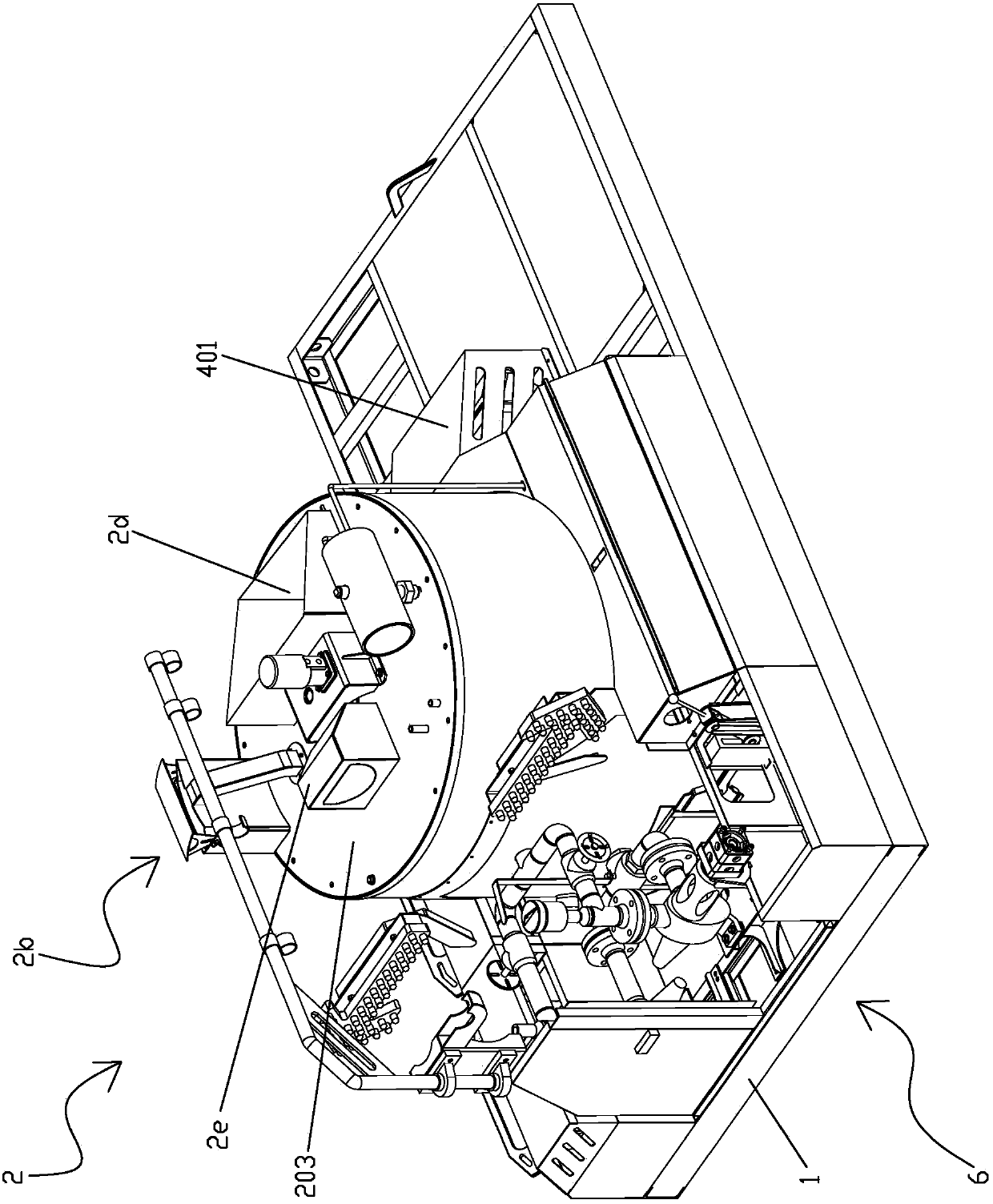

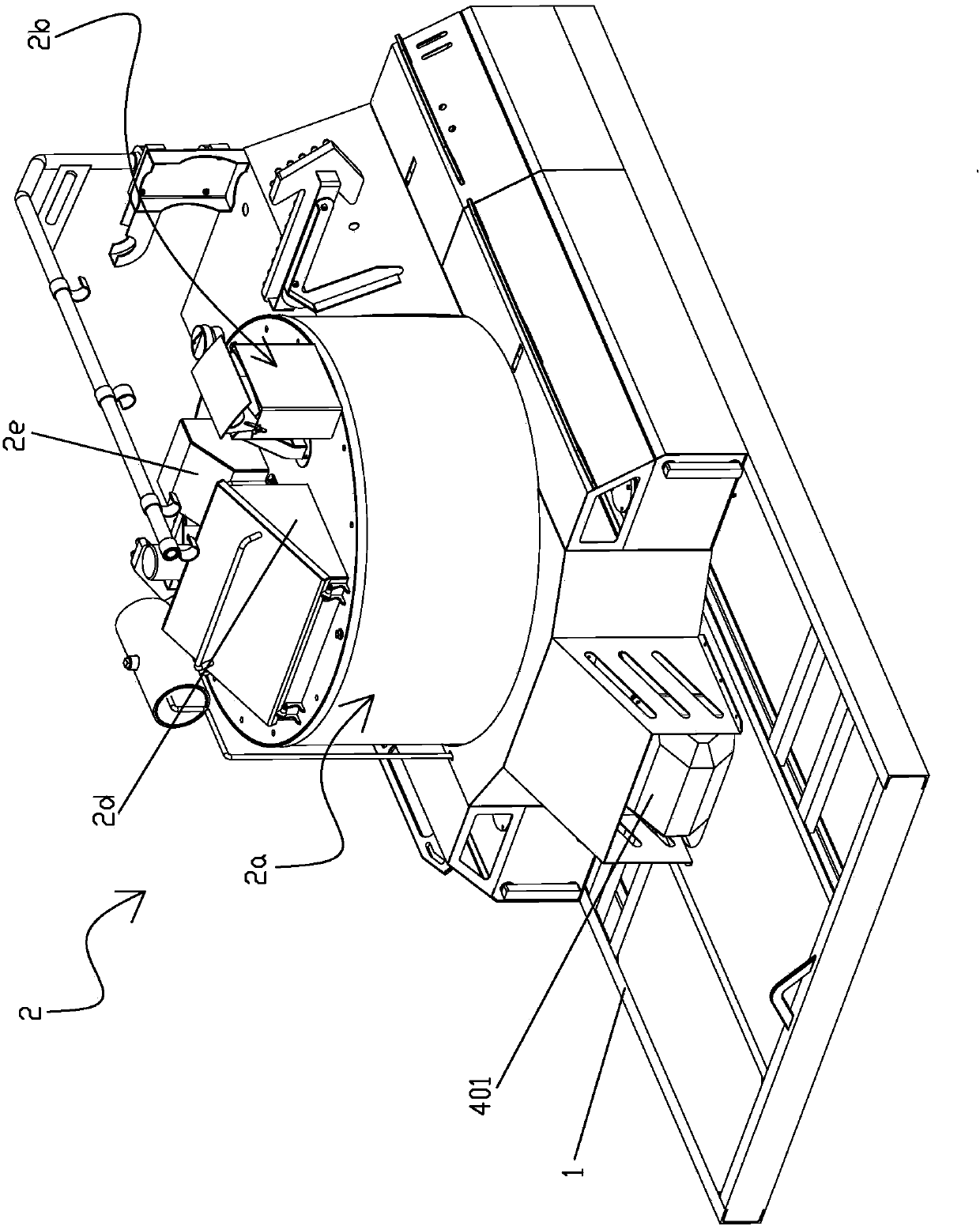

[0040] An energy-saving thermal cycle seam filling machine, comprising a frame 1, the frame 1 is provided with a heating cycle device 2, and the heating cycle device 2 includes a circulating melt chamber 201, and the circulating melt chamber 201 A stirring device 3 for stirring asphalt or joint glue is provided inside, and a temperature control device 4 for controlling the temperature in the cavity is provided on the wall of the circulating molten material chamber 201, and the temperature control device 4 includes a heating gas The burner 401, the lower side of the circulating molten material chamber 201 is provided with a hot gas circulation chamber 402 connected to the burner 401 at one end and capable of storing the gas heated by the burner 401, and the heating cycle The device 2 is provided with a hot gas circulation heating insulation layer 2a for surrou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com