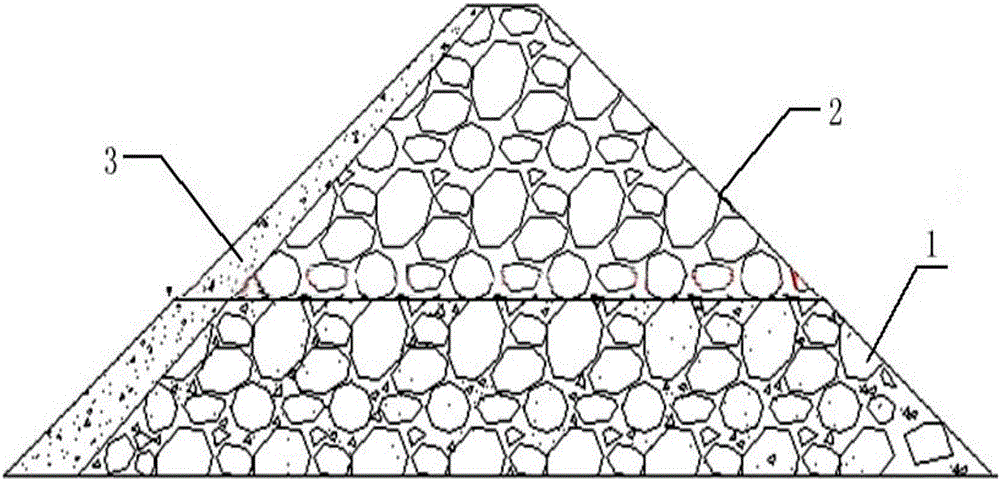

Super-high rockfill dam structure suitable for water conservancy and hydropower engineering and construction method of dam structure

A technology of water conservancy, hydropower and water conservancy projects, which is applied in the direction of dams, barrages, weirs, etc., can solve problems such as the difficulty of breaking through the limitation of dam heights, and achieve the elimination of technical development bottlenecks, less cement consumption, and strong interlayer shear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] Embodiment: use the method described in the present invention to construct the ultra-high rockfill dam knot of certain hydropower hydraulic engineering, it is characterized in that concrete steps are as follows:

[0045] (1) According to the construction specifications and relevant technical requirements of concrete face rockfill dams, the dam foundation and bank slope of the hydropower and water conservancy project are treated; the treatment steps and requirements are the same as those of the existing face rockfill dams;

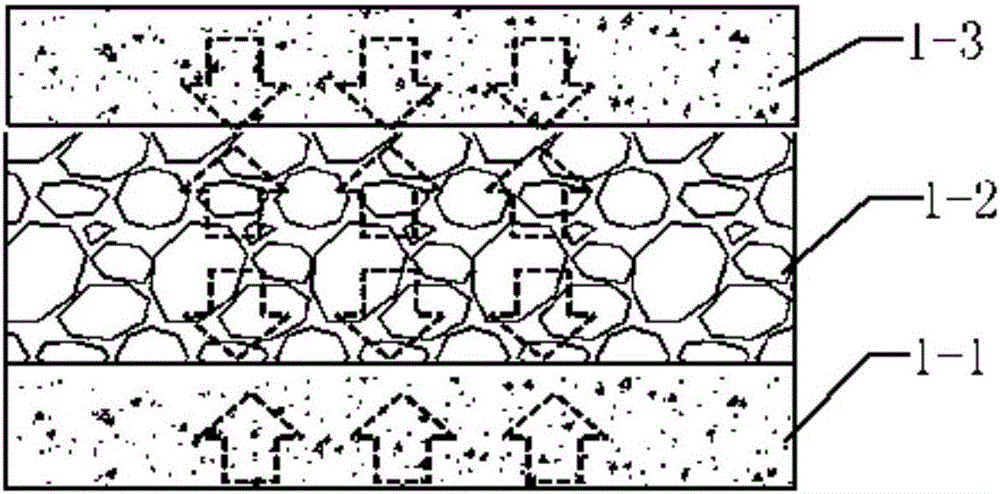

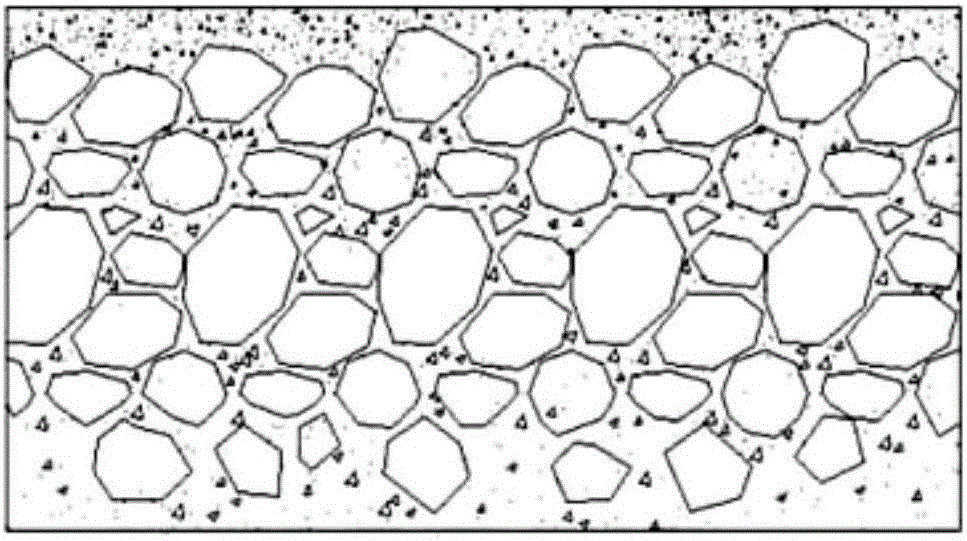

[0046] (2) The stone excavated at the construction site is roughly divided into 0-5mm, 5-20mm, 20-40mm and 40-300mm according to the particle size, or even larger particle size;

[0047] (3) Raw materials are used to prepare secondary mix concrete at the construction site, and the secondary mix concrete adopts the concrete raw materials of the project: water, cement, mineral admixture, admixture and step (2) in which the particle size is 0-5mm, 5-20m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com