Chiseling-free pile head construction method

A construction method and pile head technology, which is applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of wasting concrete and excessive labor costs, and achieve the effects of reducing construction cost, simplifying construction procedures, and improving construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

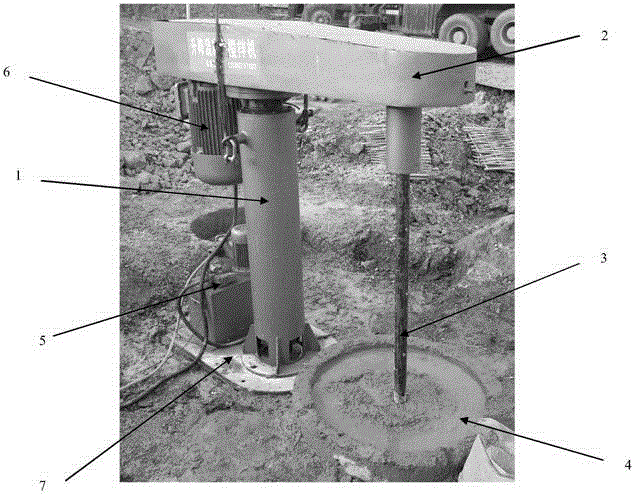

[0033] Refer to attached picture.

[0034] Exemption of the present invention removes pile head construction method and comprises the following steps:

[0035] Step 1, excavate the earthwork to the level of the bottom of the cap.

[0036] Before the hole is formed, the soil is excavated to the elevation of the bottom of the cap. In order to ensure the quality of the hole, avoid excessive hole drilling and avoid the disturbance of the pile body by the excavation after the pile is poured, the pile should be excavated before the hole is formed. The earthwork in the area will be excavated to the designed cap bottom elevation, and at the same time, a working surface will be provided for the inverted electric suspension rod in-situ stirring reinforcement method without chiseling pile heads.

[0037] Step 2, determine the concrete filling height of the pile body.

[0038] 2.1 Calculation of the rest elevation of the pile body concrete pouring: after the hole is formed, the pile bod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com