Testing device for key dimension of automotive hub shaft

A technology of key dimensions and detection devices, which is applied in the mechanical field, can solve problems such as inability to guarantee test accuracy, failure to use normally, and low work efficiency, and achieve the effects of novel structure, reduced investment, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

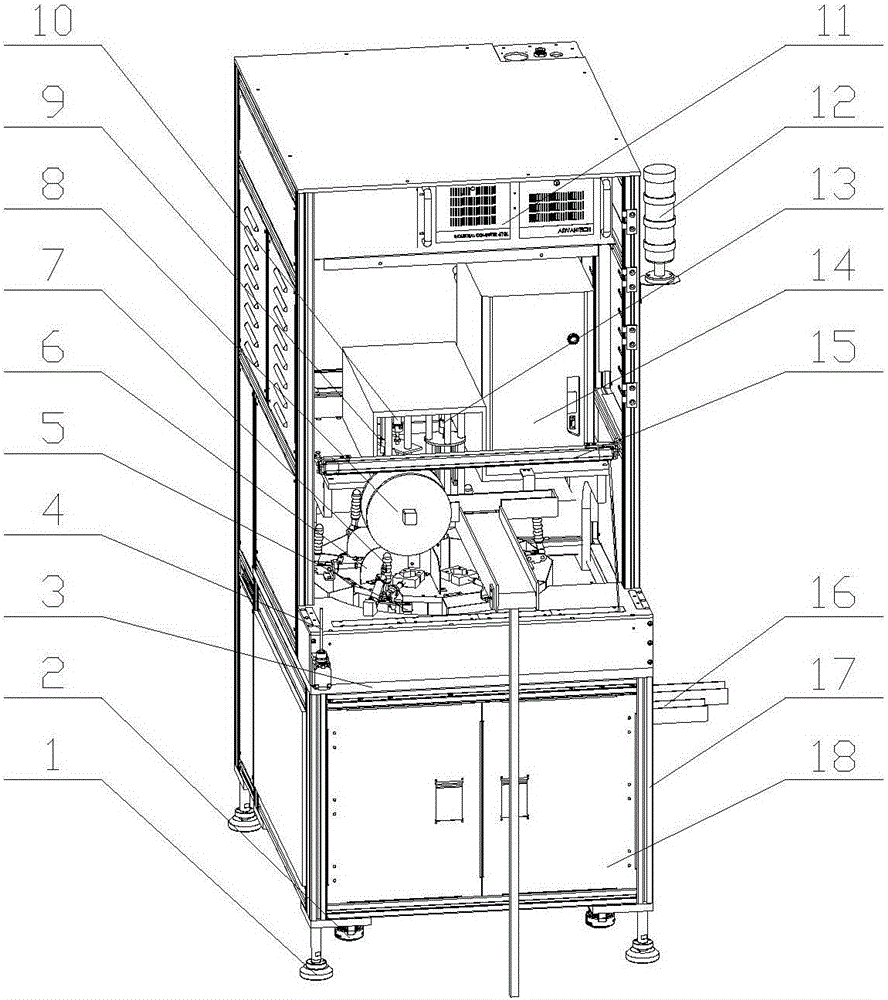

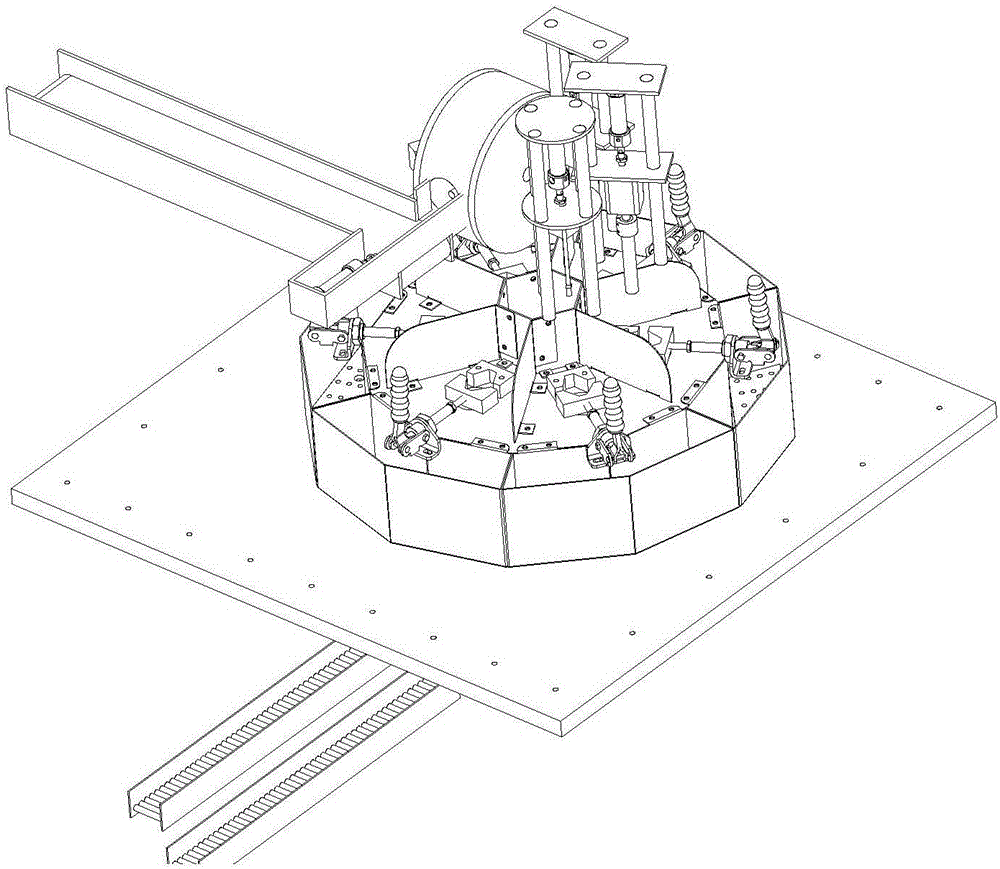

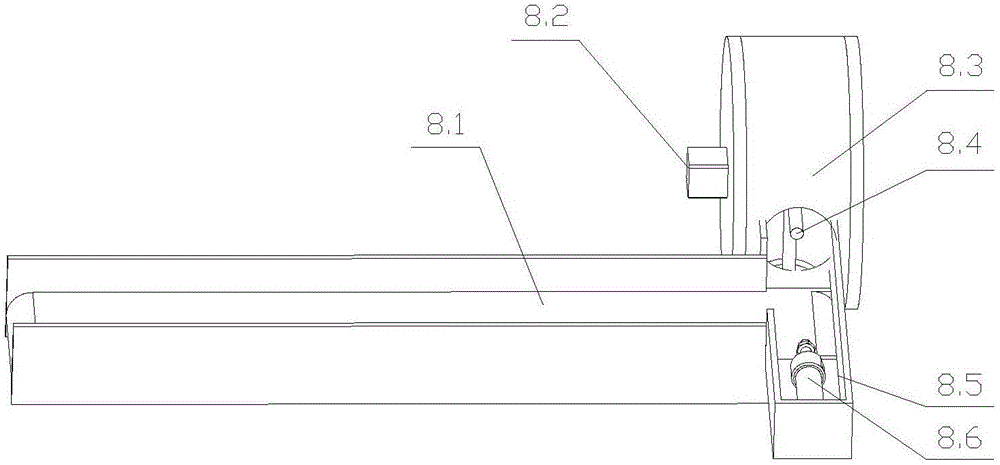

[0027] see figure 1 and figure 2As shown, the detection device for the key dimensions of the automobile hub shaft of the present invention includes an anchor 1, a roller 2, a support plate 3, a mouse tail switch 4, a small bore cylinder 5, a workbench 6, a clamping mechanism 7, a feeding mechanism 8, a Gauge detection mechanism 9, stop gauge detection mechanism 10, industrial computer 11, indicator light 12, outer diameter detection mechanism 13, laser transmitter 14, laser sensor 15, discharge mechanism 16, frame aluminum profile 17, metal sheet 18, frame aluminum The profile 17 and the thin metal plate 15 are connected together by screws to form the main body of the frame. Four feet 1 and four rollers 2 are installed at the bottom of the frame. The feet 1 are used to adjust the height of the entire device, and the rollers 2 are used Mobile device; the feeding and testing part is fixedly installed on the support plate 3 of the frame and connected together through the workbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com