Magnetic suspension solution concentration determination device capable of accelerating magnetic powder precipitation

A technology of concentration measurement and magnetic suspension, applied in the direction of material magnetic variables, etc., can solve problems such as large current, many devices, and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The technical solution of the present invention and its implementation effects will be further described below in conjunction with the accompanying drawings.

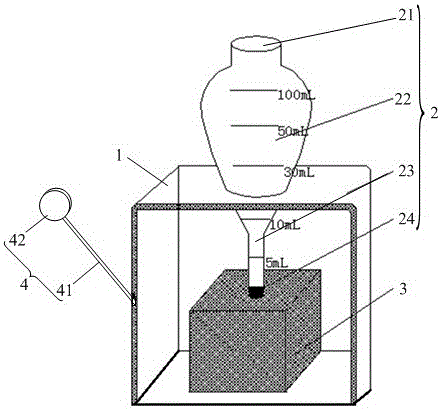

[0010] see figure 1 The above-mentioned magnetic suspension concentration measuring device for accelerating magnetic powder precipitation includes a support 1, a pear-shaped bottle 2, and a magnet 3. Positioning holes are provided on the support 1 for insertion and positioning of the pear-shaped bottle 2, and the magnet 3 is placed on the pear-shaped bottle 2. and contact with the bottom of the pear-shaped bottle 2, the pear-shaped bottle 2 comprises a top opening 21, a bottle body 22, a bottleneck 23, a bottom seal 24, and the diameter of the bottleneck 23 is less than the diameter of the bottle body 22, the bottle body 22 and the bottleneck 23 Mark the scale line on the top, and the diameter of the bottle neck 23 close to the bottom seal 24 is tapered to form an arc-shaped bottom seal 24 .

[0011] The arc-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com