Steelmaking and continuous casting scheduling method based on artificial bee colony (ABC)

An artificial bee colony algorithm, steelmaking and continuous casting technology, applied in the direction of calculation, calculation model, artificial life, etc., can solve the problems of negligible intermediate transport cranes, workpiece heating, large capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

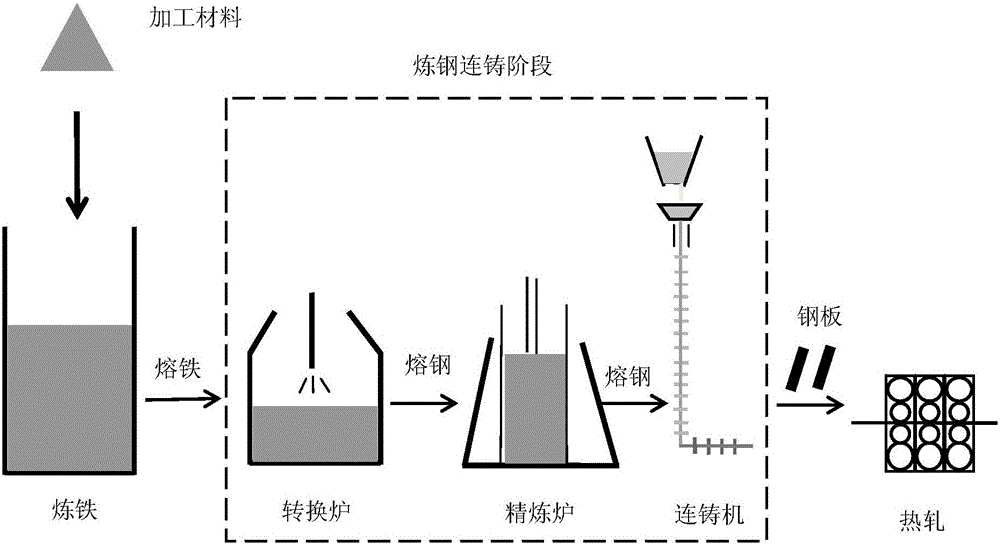

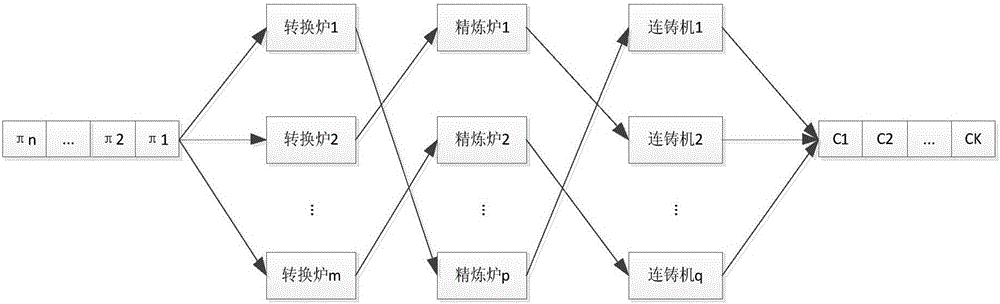

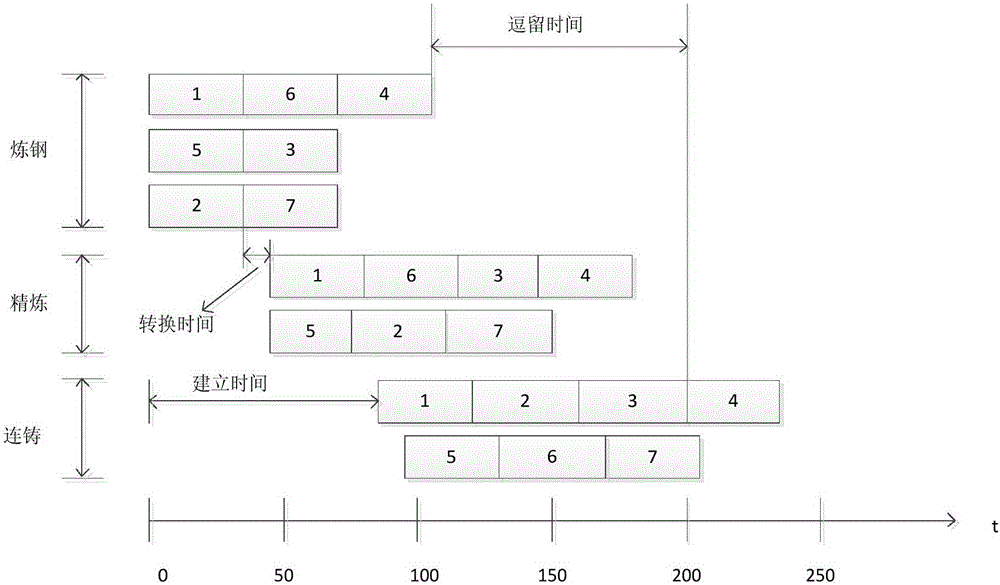

[0074] The steelmaking and continuous casting process includes three processing stages: steelmaking-refining-continuous casting, and its process flow chart is as follows figure 1 shown. The problem to be solved in the present invention is the scheduling problem of the mixed flow shop in the steelmaking and continuous casting process. The schematic diagram of the workpiece scheduling of this type of problem is as follows figure 2 As shown, it can be regarded as a mixed flow shop scheduling problem for the group production of workpieces in the final stage. In addition, to solve the scheduling problem in the actual production environment, a series of production constraints need to be considered, such as the 10 characteristics of the steelmaking scheduling problem given in the technical background, which are also constraints that need to be considered in this problem.

[0075] Before giving a more detailed description of the scheduling method in the present invention, the model ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com