Mechanical picking method of fresh fragrant tea leaf raw material in high-slope tea garden

A technology for mechanical picking and tea gardening, applied in agricultural machinery and implements, harvesters, cultivation and other directions, can solve the problems of difficulty in mechanically picking fresh tea leaves, uneven quality of fresh leaves picked by machine, and difficulty in defining and mastering methods. , to achieve the effect of being conducive to good tree vigor cultivation, improving nutrient absorption and utilization rate, and facilitating machine mining operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

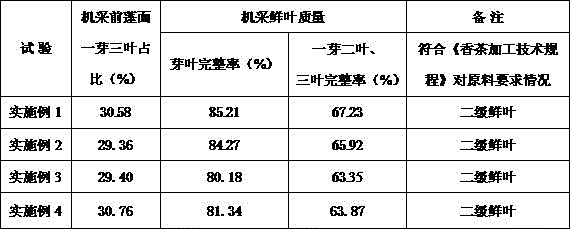

Examples

Embodiment 1

[0020] (1) Tea gardens and varieties: pick tea gardens on high slopes, with a slope of 15° and a terrace width of 1.4m. The tea tree variety is Longjing 43, a 10-year-old small-leaf species, planted in double rows, with the same growth of tea trees, and no broken rows;

[0021] (2) Cultivation of tree crowns: after the end of spring tea in the previous year, heavy pruning was carried out with a single-person pruning machine. After pruning, the height of the tea tree was 55 cm. At the same time, fertilizer cultivation was strengthened, and 100 kg of compound fertilizer was applied per mu; the second time was carried out on October 8 Clean up the surface and apply base fertilizer. Use a single pruning machine to level the crown with light pruning. The height of the tea tree after pruning is 65cm. After pruning, apply base fertilizer, 500kg of rapeseed cake and 100kg of compound fertilizer per mu;

[0022] (3) The machine-picked surface is smooth: in the spring of that year, 15 da...

Embodiment 2

[0027] (1) Tea gardens and varieties: pick tea gardens on high slopes, with a slope of 20° and a terrace width of 1.3m. The tea tree variety is Longjing 43, an 8-year-old small-leaf species, planted in double rows, with the same growth of tea trees, and no broken rows;

[0028] (2) Cultivation of tree crowns: after the end of spring tea in the previous year, heavy pruning was carried out with a single-person pruning machine. After pruning, the height of the tea tree was 55 cm. At the same time, fertilizer cultivation was strengthened, and 100 kg of compound fertilizer was applied per mu; the second time was carried out on October 8 Clean up the surface and apply base fertilizer. Use a single pruning machine to level the crown with light pruning. The height of the tea tree after pruning is 65cm. After pruning, apply base fertilizer, 500kg of rapeseed cake and 100kg of compound fertilizer per mu;

[0029] (3) The machine-picked surface is smooth: In the spring of that year, 18 da...

Embodiment 3

[0034] (1) Tea gardens and varieties: Pick tea gardens on high slopes, with a slope of 15° and a terrace width of 1.4m. The tea tree variety is Yingshuang, a 10-year-old mid-leaf species, planted in double rows, with consistent growth of tea trees, and no broken rows;

[0035] (2) Cultivation of tree crowns: after the end of spring tea in the previous year, heavy pruning was carried out with a single-person pruning machine. After pruning, the height of the tea tree was 55 cm. At the same time, fertilizer cultivation was strengthened, and 100 kg of compound fertilizer was applied per mu; the second time was carried out on October 8 Clean up the surface and apply base fertilizer. Use a single pruning machine to level the crown with light pruning. The height of the tea tree after pruning is 65cm. After pruning, apply base fertilizer, 500kg of rapeseed cake and 100kg of compound fertilizer per mu;

[0036] (3) The machine-picked surface is smooth: in the spring of that year, 15 day...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com