Micro-structure body and preparation method thereof

A technology of microstructures and microneedles, which is applied in the fields of biomedicine and medical cosmetology, and can solve problems such as unsatisfactory needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: Preparation of microstructure

[0029] Take 1.5g of hyaluronic acid and 0.5g of sodium carboxymethylcellulose dissolved in 50ml of water for injection to form a gel, adjust the pH to 7.0, and put the gel into the delivery system.

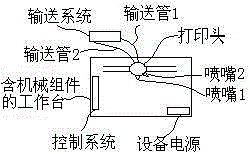

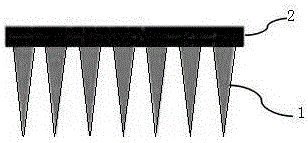

[0030] Input the microstructure instruction of printing conical microneedles of consistent height through the computer to the control system of the 3D printer. The gel was delivered to the nozzle of the print head, printed into substrate and microneedles through the nozzle, dried naturally for 12 hours, and finally sterilized by ethylene oxide. The performance parameters of the microstructure prepared by this method are shown in Table 1.

[0031] Table 1.

[0032]

Embodiment 2

[0033] Embodiment 2: Preparation of microstructure

[0034] Take 2g of hyaluronic acid and 0.1g of collagen and dissolve 80ml of water for injection to form a gel, adjust the pH to 7.2, and put the gel into the delivery system.

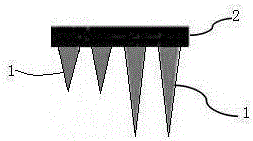

[0035] Input the instruction of printing conical microneedles of different heights to the control system of the 3D printer through the computer. The gel is transported to the nozzle of the print head, printed into substrates and microneedles through the nozzle, dried at 95°C for 5s, and finally sterilized with ethylene oxide. The performance parameters of the microstructure prepared by this method are shown in Table 2.

[0036] Table 2.

[0037]

Embodiment 3

[0038] Embodiment three: preparation of microstructure

[0039] Add 1g of hyaluronic acid to 15ml of water, add BDDE according to 0.001% (W / W) of hyaluronic acid, cross-link under alkaline conditions, swell with neutral physiological isotonic phosphate buffer to form a gel, and then gel Mix 2% (W / W) polylactic acid-glycolic acid into the gel, adjust the pH to 7.0, and load the gel into the delivery system.

[0040]Input the microstructure command of printing cylindrical microneedles of consistent height to the control system of the 3D printer through the computer, the control system sends out the command, the print head starts after receiving the command through WIFI and the feeding system is turned on, and the feeding system sends the gel Delivered to the nozzles of the print head, the substrate and microneedles are printed through the nozzles, dried at 35°C for 4 hours, and finally sterilized by irradiation at 60°C. The performance parameters of the microstructure prepared ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com